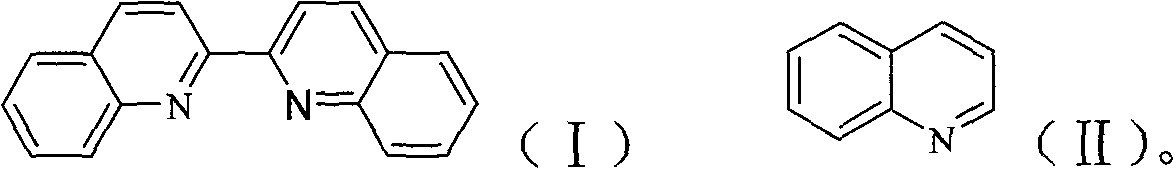

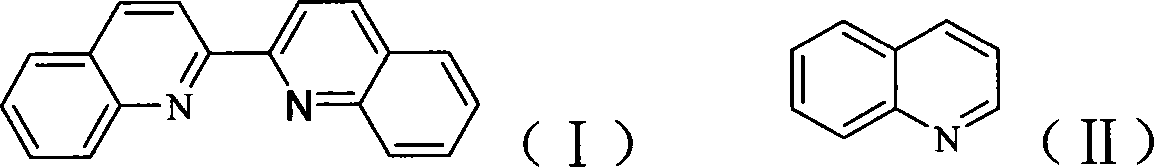

Method for synthesizing 2,2'-biquinoline

A synthesis method and biquinoline technology are applied in 2 fields, can solve problems such as unfavorable industrial production, low product purity, expensive catalyst, etc., and achieve the effects of low cost, simple post-processing, and no reduction in yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

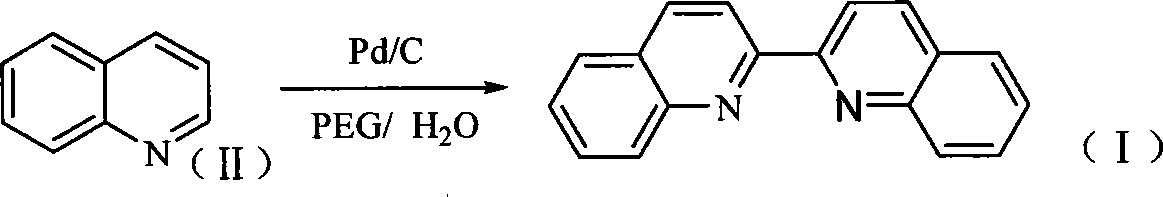

Method used

Image

Examples

Embodiment 1

[0026] In a 50 mL round bottom flask, add H 2 O (5.0g), PEG-400 (1.0g), quinoline (1.0g), after stirring evenly, add 1% Pd / C catalyst (0.1g) and react at 80°C for 20h, cool the reaction solution and suction filter, The filter cake Pd / C was washed with water, which can be recycled and reused; the filtrate was extracted with ethyl acetate, the solvent was evaporated, concentrated, and crystals were precipitated to obtain a crude product, which was recrystallized to obtain 0.12 g of white 2,2'-biquinoline crystals. The yield is 11.9%, and the melting point is 196-197°C. 1 H NMR (400MHz, CDCl 3 )δppm: 8.86 (d, 2H, J = 8.1Hz), 8.34 (d, 2H, J = 8.6Hz), 8.25 (dd, 2H, J = 2.4Hz), 7.89 (dd, 2H, J = 7.0Hz) , 7.59(m, 2H), 7.77(m, 2H); 13 C NMR (CDCl 3 ) δppm: 152, 147.5, 137, 129.5, 128.0, 127.5, 127.0, 119.0; MS (EI): m / z (%): 256 (100) [M + ], 128(30), 101(13).

Embodiment 2

[0028] In a 50 mL round bottom flask, add H 2 O (1.0g), PEG-1000 (2.0g), quinoline (1.0g), after stirring evenly, add 10% Pd / C catalyst (0.4g) and react at 140°C for 15h, cool the reaction solution and suction filter, The filter cake Pd / C was washed with water and could be recycled and reused; the filtrate was extracted with ethyl acetate, the solvent was evaporated, concentrated, and crystals were precipitated to obtain a crude product, which was recrystallized to obtain 0.53 g of white crystals, with a yield of 52.6%.

Embodiment 3

[0030] In a 50 mL round bottom flask, add H 2 O (3.0g), PEG-400 (3.0g), quinoline (1.0g), after stirring evenly, add 5% Pd / C catalyst (1.0g) and react at 120°C for 4h, cool the reaction solution and suction filter, The filter cake Pd / C was washed with water and could be recycled and reused; the filtrate was extracted with ethyl acetate, the solvent was evaporated, concentrated, and crystals were precipitated to obtain a crude product, which was recrystallized to obtain 0.58 g of white crystals, with a yield of 57.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com