Method for extracting gibberellic acid GA4+7 from gibberellic acid fermentation liquor

A gibberellic acid and fermented liquid technology, applied in the direction of organic chemistry, can solve the problems of high production cost, low yield, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

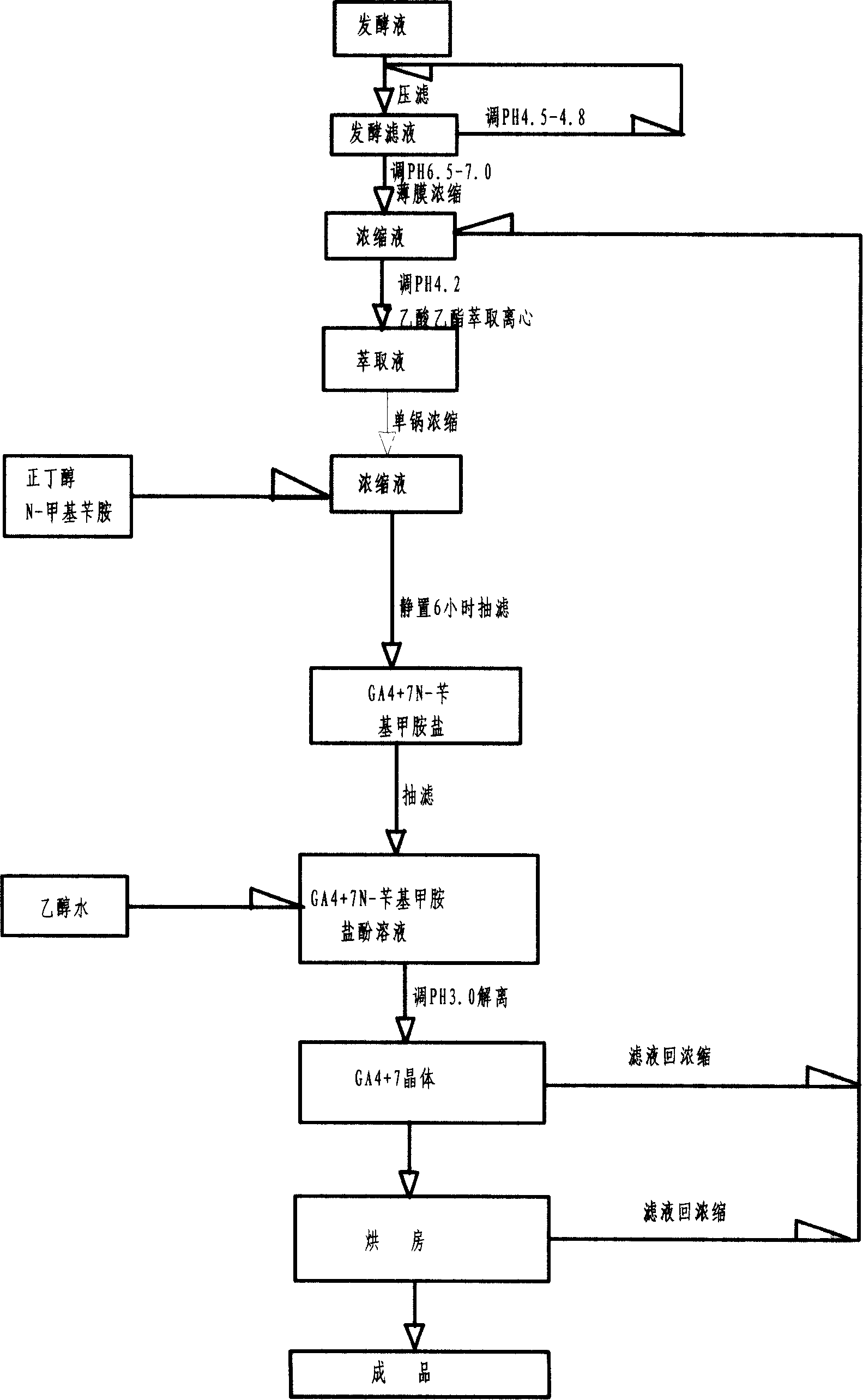

Image

Examples

Embodiment 1

[0017] (1): Get 20 tons of gibberellin A4+7 fermented liquid of gibberellin A4+7 bacterial classification through fermentation culture, measured pH value is 5.95, and fermentation unit is 872 μ / ml; Press out filtrate 16 through plate and frame filter press tons, the pH value is 5.90, and the appearance of the filtrate is light gray;

[0018] (2): above-mentioned filtrate is adjusted pH value with oxalic acid to be 4.0-5.0, then fully stirs 15 minutes, then enters plate and frame filter press again, utilizes original filter cake layer to filter, and filtrate after filtering is light yellow transparent body, this Press out 16.5 tons of filtrate through the plate and frame filter press;

[0019] (3): the former filter cake layer is washed with 10 tons of water with a pH value of 6.5-7.5, and the filtrate collected through cleaning is mixed with the filtrate obtained in the second step above;

[0020] (4) the mixed solution of the third step is regulated to 6.5-7.0 with soda ash ...

Embodiment 2

[0026] (1): Get 18.5 tons of gibberellin A4+7 fermented liquid of gibberellin A4+7 bacterial strain through fermentation culture, measured pH value is 6.12, and fermentation unit is 860 μ / ml; Press out filtrate 14.8 through plate and frame filter press tons, the pH value is 6.11, and the appearance of the filtrate is light gray;

[0027] (2): above-mentioned filtrate is adjusted pH value with oxalic acid to be 4.0-5.0, then fully stirs 15 minutes, then enters plate and frame filter press again, utilizes original filter cake layer to filter, and filtrate after filtering is light yellow transparent body, this Press out 15 tons of filtrate through the plate and frame filter press;

[0028] (3): the former filter cake layer is washed with 9 tons of water with a pH value of 6.5-7.5, and the filtrate collected through cleaning is mixed with the filtrate obtained in the second step above;

[0029] (4): the mixed solution of the third step is regulated to 6.5-7.0 with soda ash to 6.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com