Thermoplasticity elastic sock processing method

A technology of thermoplastic elasticity and thermoplastic elastomer, which is applied in the direction of insoles, metal processing, footwear, etc., and can solve problems such as softness and poor resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

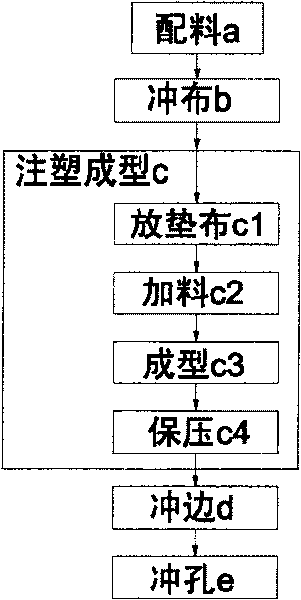

[0042] A method for processing thermoplastic elastic insoles. TPR thermoplastic elastomer (thermoplastic rubber) is selected as the main raw material. TPR thermoplastic elastomer is based on styrene-ethylene / butylene-styrene (SEBB) polymer as the main raw material, and naphthenic Oil and other polymers (such as PP) are mixed in a certain proportion. The processing method uses the following processing steps, such as figure 1 , 2 Shown:

[0043] a. Ingredients: TPR thermoplastic elastomer and toner, according to the weight ratio of 10000:8 or 10000:12 or 10000:16, it is best to use the weight ratio of 10000:12; send it to the kneader to knead 20 or 30 or 40 minutes, the best kneading time is 30 minutes;

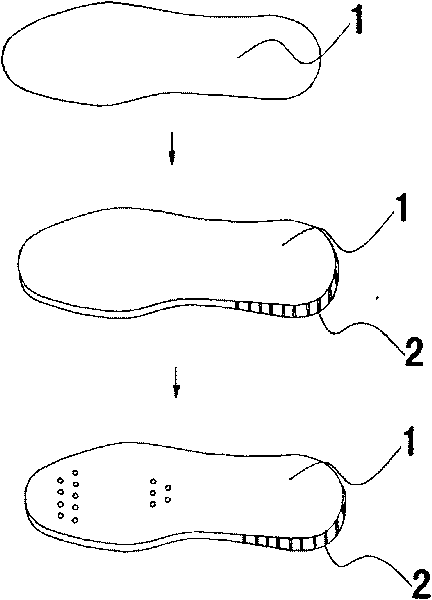

[0044] b. Punching: The fabric base material is punched into the required insole mold shape to form the cushion cloth 1 (to fit the shape of the insole). The fabric base material in this embodiment is a composite cloth, which is composed of a layer of velvet and a white pair The s...

Embodiment 2

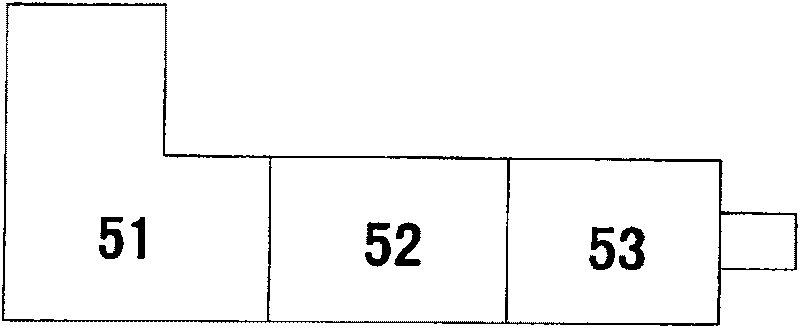

[0056] A method for processing a thermoplastic elastic insole. The difference between this embodiment and the first embodiment is that the thermoplastic elastic insole of the present invention is a two-color insole, which includes the cloth 1, the insole body 2 and the small insole 3 from top to bottom; this embodiment The color of the insole body 2 of the thermoplastic elastic insole of the example and the color of the small insole 3 are different. When injecting two-color insoles, it is two injection molding; according to the structural requirements of the insoles, a lower mold and two upper molds are designed. The injection molding process is as follows, such as Figure 4 , 5 Shown:

[0057] a. Ingredients: TPR thermoplastic elastomer and toner, according to the weight ratio of 10000:8 or 10000:12 or 10000:16, it is best to use the weight ratio of 10000:12; send it to the kneader to knead 20 or 30 or 40 minutes, the best kneading time is 30 minutes;

[0058] b. Punching: The fa...

Embodiment 3

[0074] A method for processing a thermoplastic elastic insole. The difference between this embodiment and the second embodiment is that the thermoplastic elastic insole of the present invention is a three-color insole, which includes a cloth cushion 1, an insole body 2, an insole middle piece 4, and an insole small piece 3. Among them, the insole middle piece 4 is provided with a through groove, the insole small piece 3 is located in the through groove of the insole middle piece 4, the insole body 2 is located under the cloth 1, and the insole small piece 3 and the insole middle piece 4 are located under the insole body 2. The color of the insole body 2, the color of the small insole 3, and the color of the middle part of the insole 4 of the thermoplastic elastic insole of this embodiment are all different. When injecting the three-color insole, it is three injection molding; according to the structural requirements of the insole, design a lower mold, two upper molds, and anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com