Slag included lime cream slag removing method and device

A technology of lime milk and slag removal, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of unusable, short screen life, large consumption of lime milk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

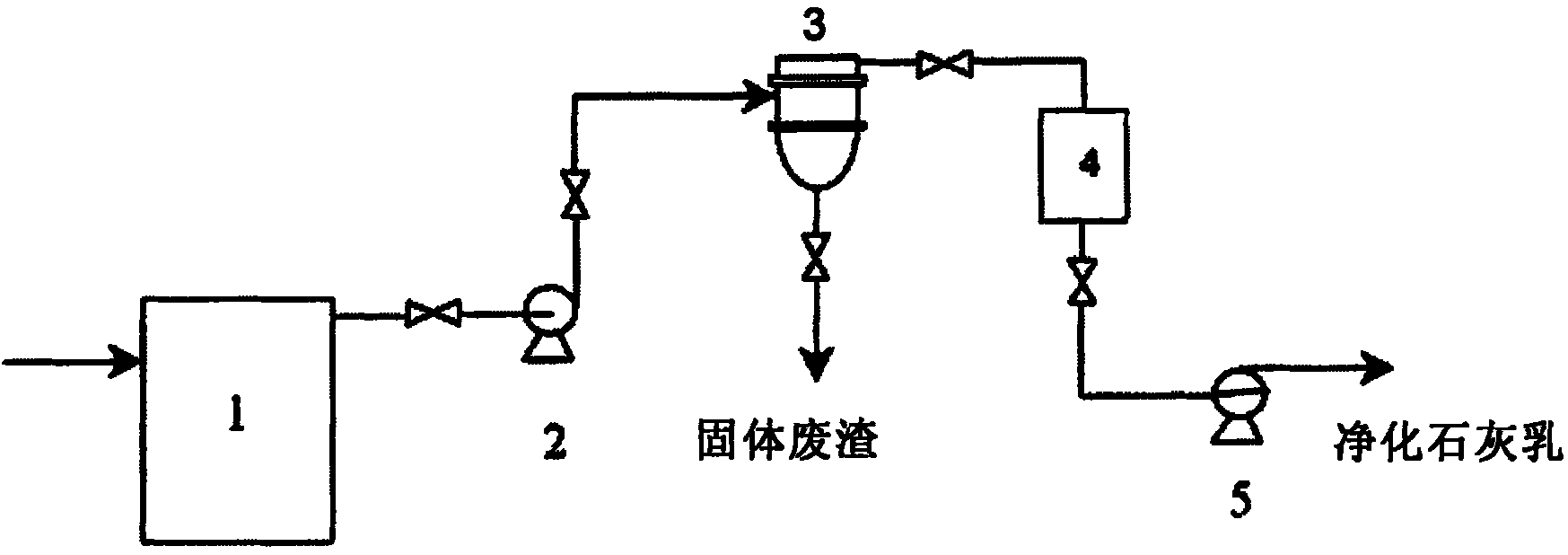

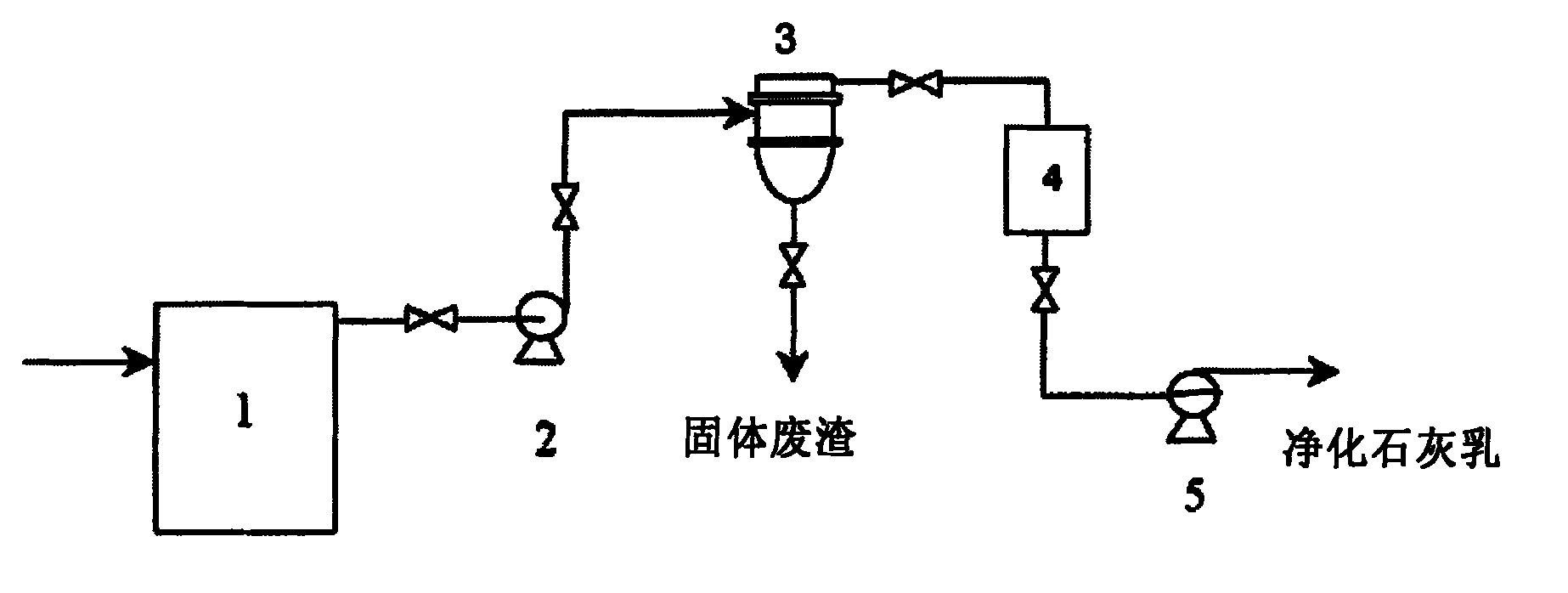

[0058] in a 25m 3 In the propylene oxide plant on the scale of / h, a set of slag-containing lime milk deslagging device as shown in Figure 1 is set up. Its specific operation process and effects are described as follows:

[0059] The capacity of gravity settling tank 1 is 6000m 3 , the lime milk capacity is about 5000m 3 , when the tank inlet flow rate is 26m 3 / h, the slag-containing lime milk goes in and out at the same time. The milk of lime pressure in the gravity settling tank 1 is normal pressure, which is lower than the minimum driving pressure of the solid-liquid cyclone separator 3, so the milk of lime needs to be pressurized. The frequency conversion booster pump 2 is used to increase the pressure of the slag-containing lime milk to 0.5-0.8 MPa, and press it into the solid-liquid cyclone separator 3 . The slag-containing milk of lime is separated into low-concentration milk of lime and solid waste residue. The solid waste is under normal pressure, and the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com