Method for producing dichlormide

A technology of dichloropropenamine and a production method is applied in chemical instruments and methods, preparation of carboxylic acid amides, preparation of organic compounds, etc., and can solve the problems of low operational safety, difficult popularization and application, large fixed investment and the like, Achieve the effect of high product content, prominent substantive characteristics and small fixed investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

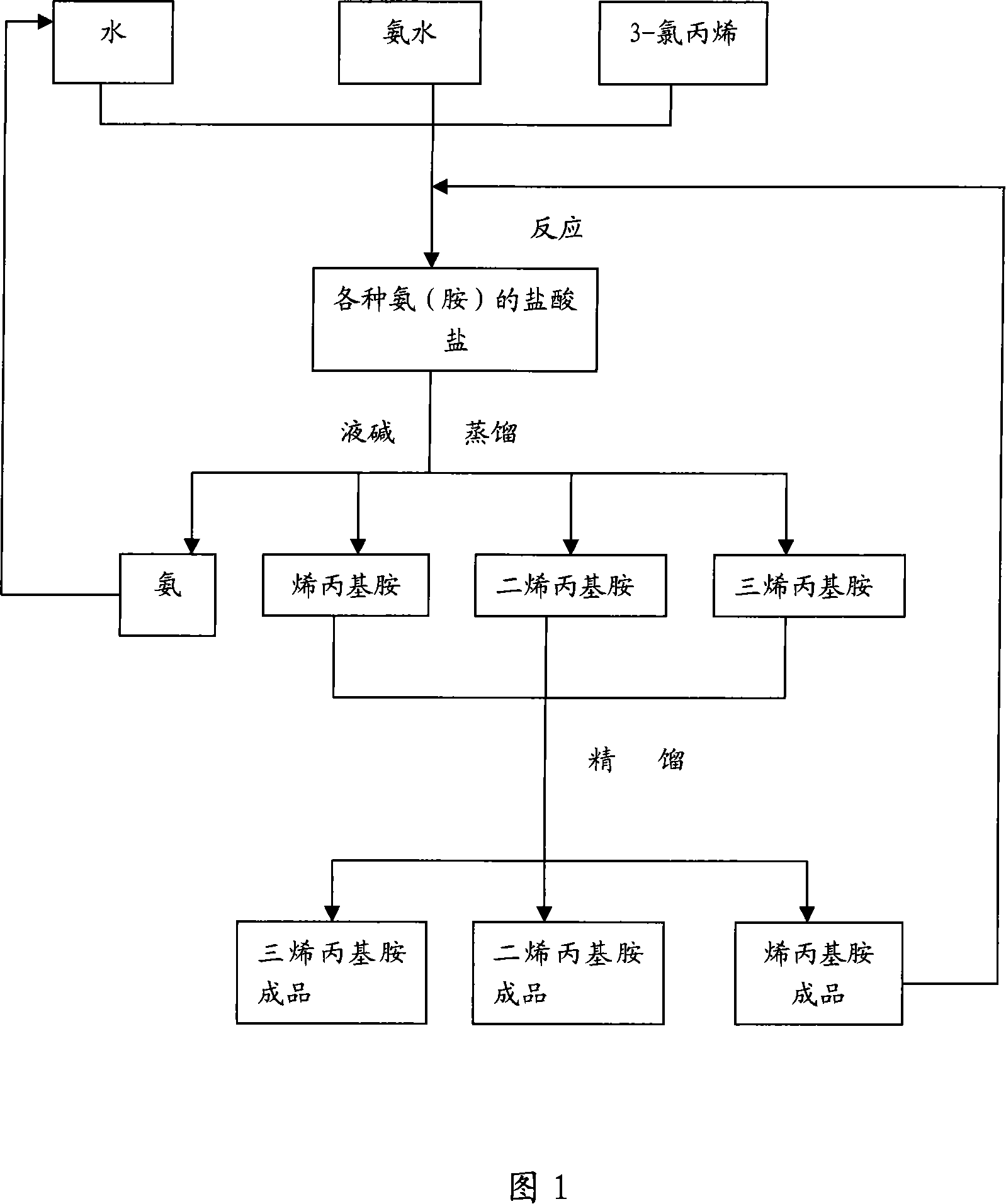

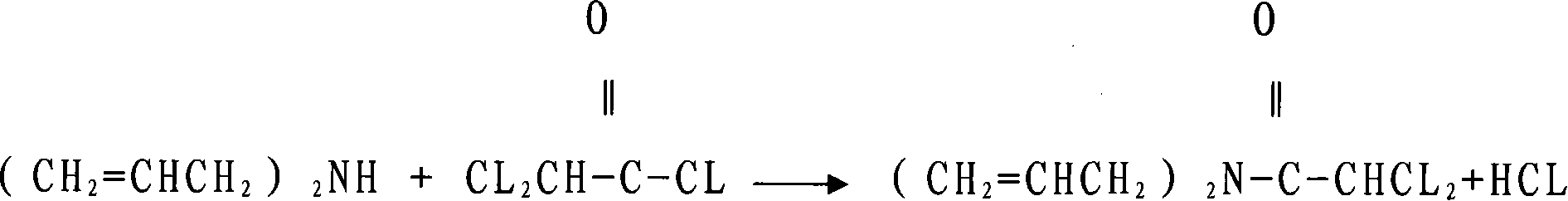

Method used

Image

Examples

Embodiment 1

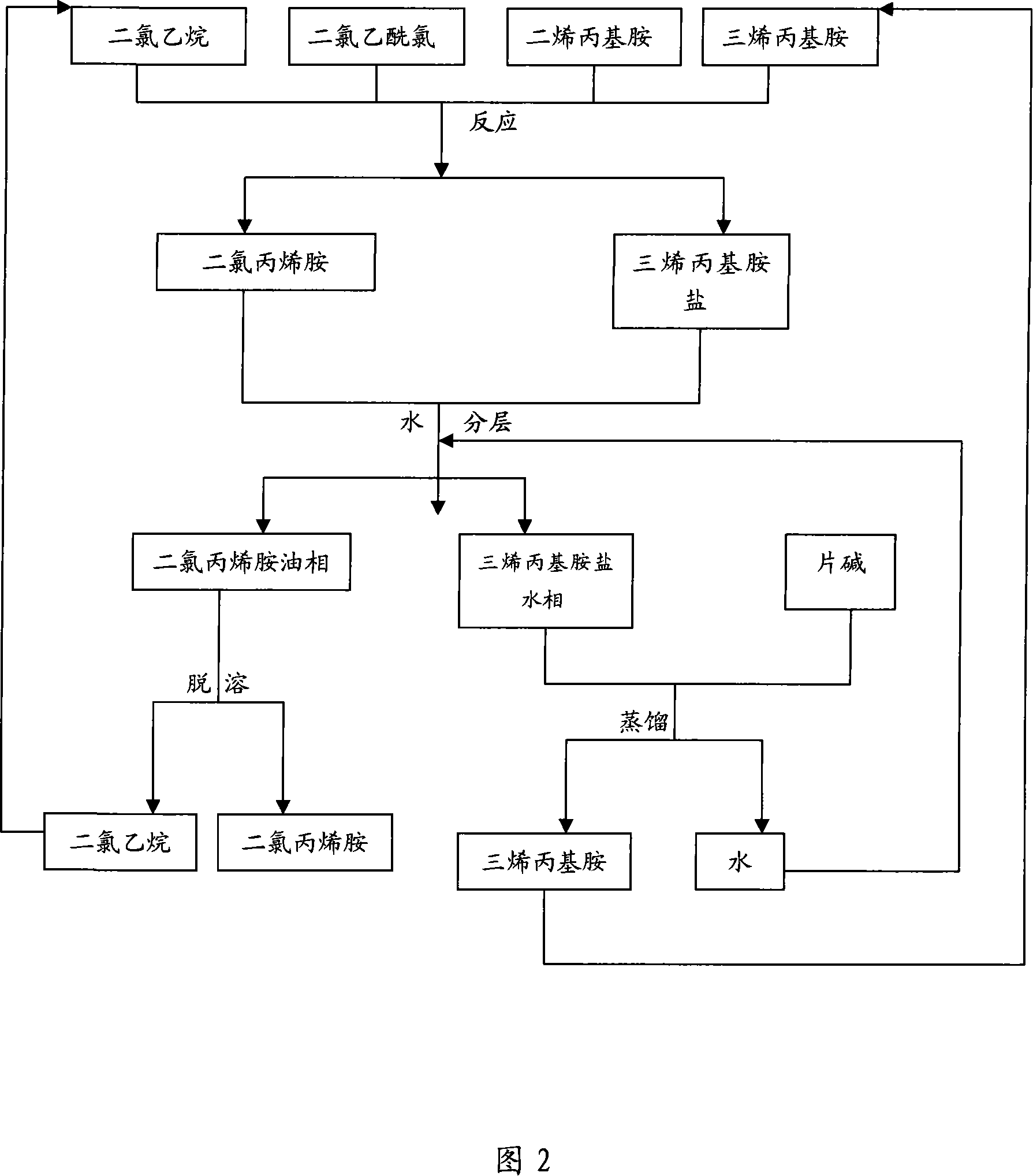

[0031] Use a pump to put 226.7kg of ammonia water (concentration is about 15%) into the reaction kettle, and at the same time put 0.306kg of methylamine and 0.306kg of propylene from the large valve, and pump 153kg of 3-chloropropene into the dripping tank. Add 3-chloropropene dropwise under normal pressure. After the dropwise addition, slowly raise the temperature to 30-50°C, keep it warm for about 1 hour, then lower the temperature, put the material liquid into the still, and steam until the water phase appears to stop, that is, diallyl Crude amine, put the crude product of diallylamine into the rectification kettle to rectify diallylamine (the mixture of diallylamine, allylamine and triallylamine, the same below), diallylamine The base amine yield was 75% (calculated as 3-chloropropene, the same below), which was 72.75kg. Put the rectified diallylamine into the drip tank, pump 291kg of dichloroethane, 105kg of dichloroacetyl chloride, and 98.6kg of triallylamine into the re...

Embodiment 2

[0033] Use a pump to put 340kg of ammonia water (concentration is about 15%) into the reaction kettle, and at the same time, put 1.53kg of methylamine and 1.53kg of propylene from the large valve, pump 153kg of 3-chloropropene into the dripping tank, start stirring, normal temperature and pressure Add 3-chloropropene dropwise, after the dropwise addition, slowly raise the temperature to 30-50°C, keep it warm for about 1 hour, then lower the temperature, put the material liquid into the distillation kettle, and steam until the water phase appears to stop, that is, the crude product of diallylamine , put the crude product of diallylamine into a rectifying still to rectify diallylamine, and the yield of diallylamine is 75.2%, which is 72.9kg. Put the rectified diallylamine into the drip tank, pump 291.6kg of dichloroethane, 105kg of dichloroacetyl chloride, and 98.1kg of triallylamine into the reaction kettle, start stirring, and Slowly add diallylamine dropwise, and the temperat...

Embodiment 3

[0035] Use a pump to put 283.3kg of ammonia water (concentration is about 15%) into the reaction kettle, and at the same time, put 0.765kg of methylamine and 0.765kg of ethylene from the large valve, and pump 153kg of 3-chloropropene into the dripping tank, start stirring, and keep it at room temperature. Add 3-chloropropene dropwise under pressure. After the dropwise addition, slowly raise the temperature to 30-50°C, keep it warm for about 1 hour, then lower the temperature, put the material liquid into the distillation kettle, and steam until the water phase appears to stop, that is, diallylamine Crude product, put the crude product of diallylamine into a rectification kettle to rectify diallylamine, the yield of diallylamine is 75.1%, which is 72.8kg. Put the rectified diallylamine into the drip tank, pump 291kg of dichloroethane, 105kg of dichloroacetyl chloride, and 97.9kg of triallylamine into the reaction kettle, start stirring, and slowly Add diallylamine dropwise, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com