Method for extracting polysaccharide from jujube

A technology of jujube polysaccharides and jujube, which is applied in the field of natural product extraction, can solve the problems of no polysaccharide extraction, and achieve the effects of low cost, simple operation, and increased polysaccharide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

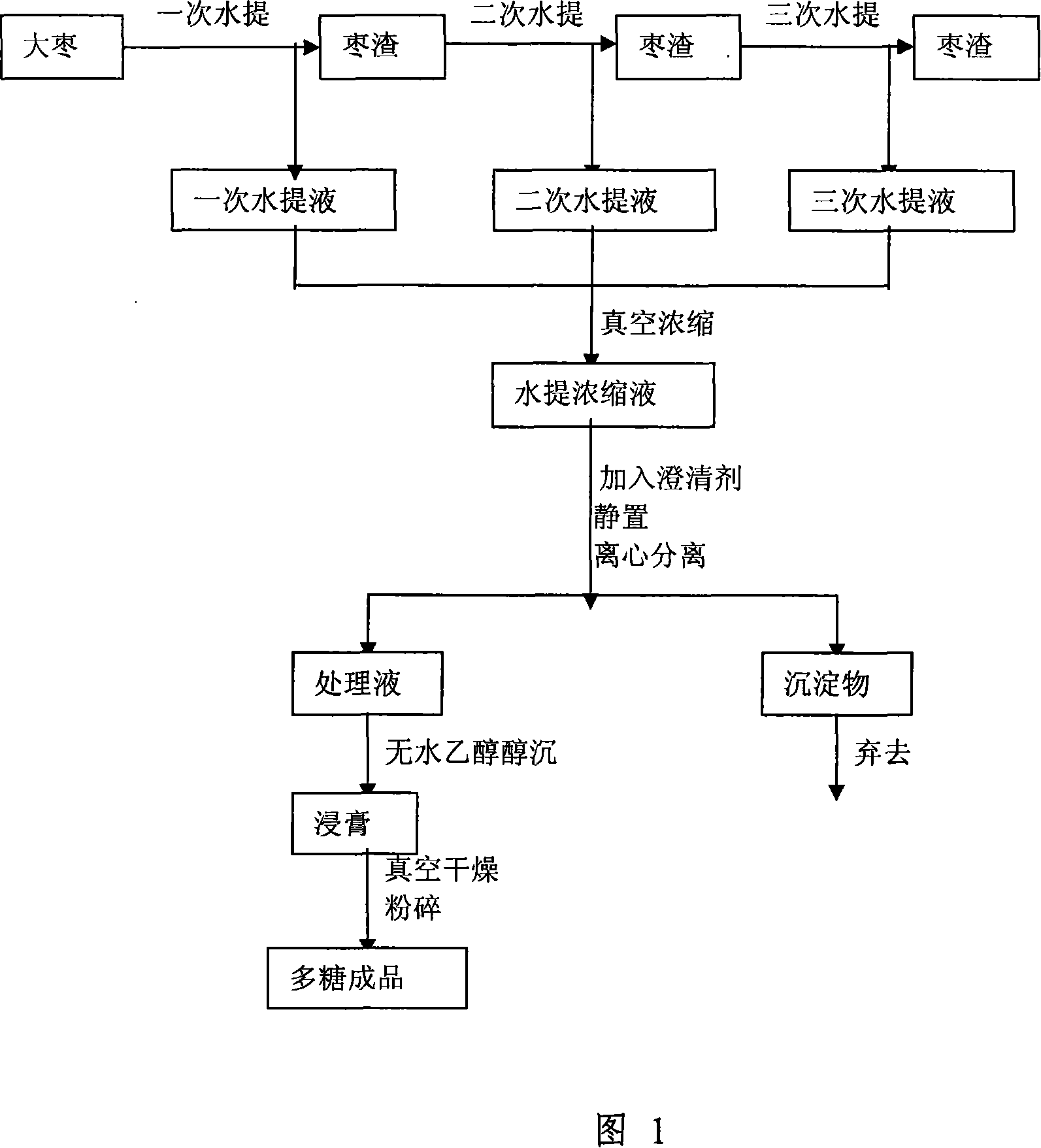

[0018] As shown in Figure 1, weigh 1 Kg of jujube that has been denuclearized and dried to constant weight, add 15 L of distilled water, and extract at 80 ° C for three times under reflux. Jujube and water mass volume ratio is 1: 8g / ml Concentrate under reduced pressure, add 1L of 1% chitosan acetic acid solution to the concentrated solution, after stirring evenly, let it stand for a certain period of time, and centrifuge; add anhydrous Ethanol, so that the volume concentration of ethanol reaches 70%, centrifuged after overnight alcohol precipitation; the obtained solid is dried to constant weight, and the jujube polysaccharide product is obtained. The yield of the obtained polysaccharide is 4.71%, and the content is 46.5%.

Embodiment 2

[0020] Weigh 20g of jujube that has been denuclearized and dried to constant weight, add 200ml of distilled water, and extract twice under reflux at 85°C. Mass volume ratio is 1: 5g / ml concentrating under reduced pressure, adds 1% chitosan acetic acid solution 20ml to concentrated solution, after stirring evenly, let stand for a certain period of time, centrifugal separation; The volume concentration reaches 70%, centrifuged after alcohol precipitation overnight; the obtained solid is dried to constant weight, and the jujube polysaccharide product is obtained. The obtained polysaccharide yield was 4.82%, and the content was 46.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com