Minisize electromagnetic low-frequency vibration energy collecting device

An energy harvester and low-frequency vibration technology, applied in the field of harvesters, can solve the problems of high battery replacement cost, difficult maintenance, large volume and mass, etc., and achieve the effects of easy mass production, ensuring structural reliability, and improving harvesting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

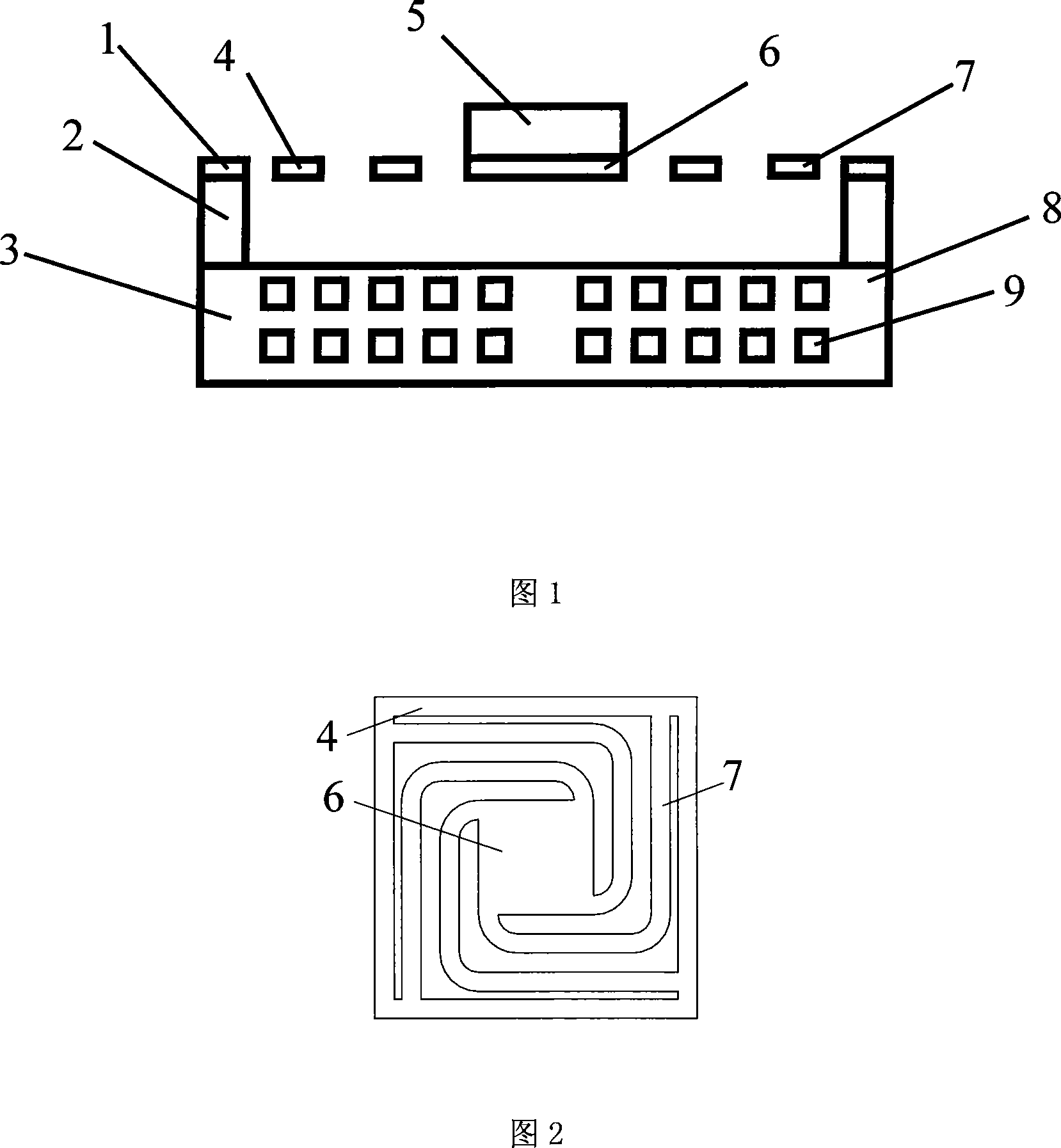

[0023] As shown in FIG. 1 , this embodiment includes: a vibration pickup structure 1 , a support structure 2 and a microcoil 3 . The support structure 2 is located around the vibration pickup structure 1 , and the vibration pickup structure 1 and the support structure 2 are located above the microcoil 3 .

[0024] As shown in FIG. 2 , the vibration pickup structure 1 includes: a metal planar spring 4 and a permanent magnet 5 . The metal planar spring 4 includes four elastic arms 7 and a metal platform 6 in the middle. The permanent magnet 5 is located on the metal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com