Water-saving electricity-saving reverse osmosis water purifying machine

A pure water machine and reverse osmosis technology, which is applied in the field of water treatment, can solve the problems that high-pressure pumps cannot be idled without water and frequent start and stop, affect high-pressure pumps, and high-pressure pumps are heavily loaded, so as to provide water quality by quality and eliminate The effect of frequent start and stop and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

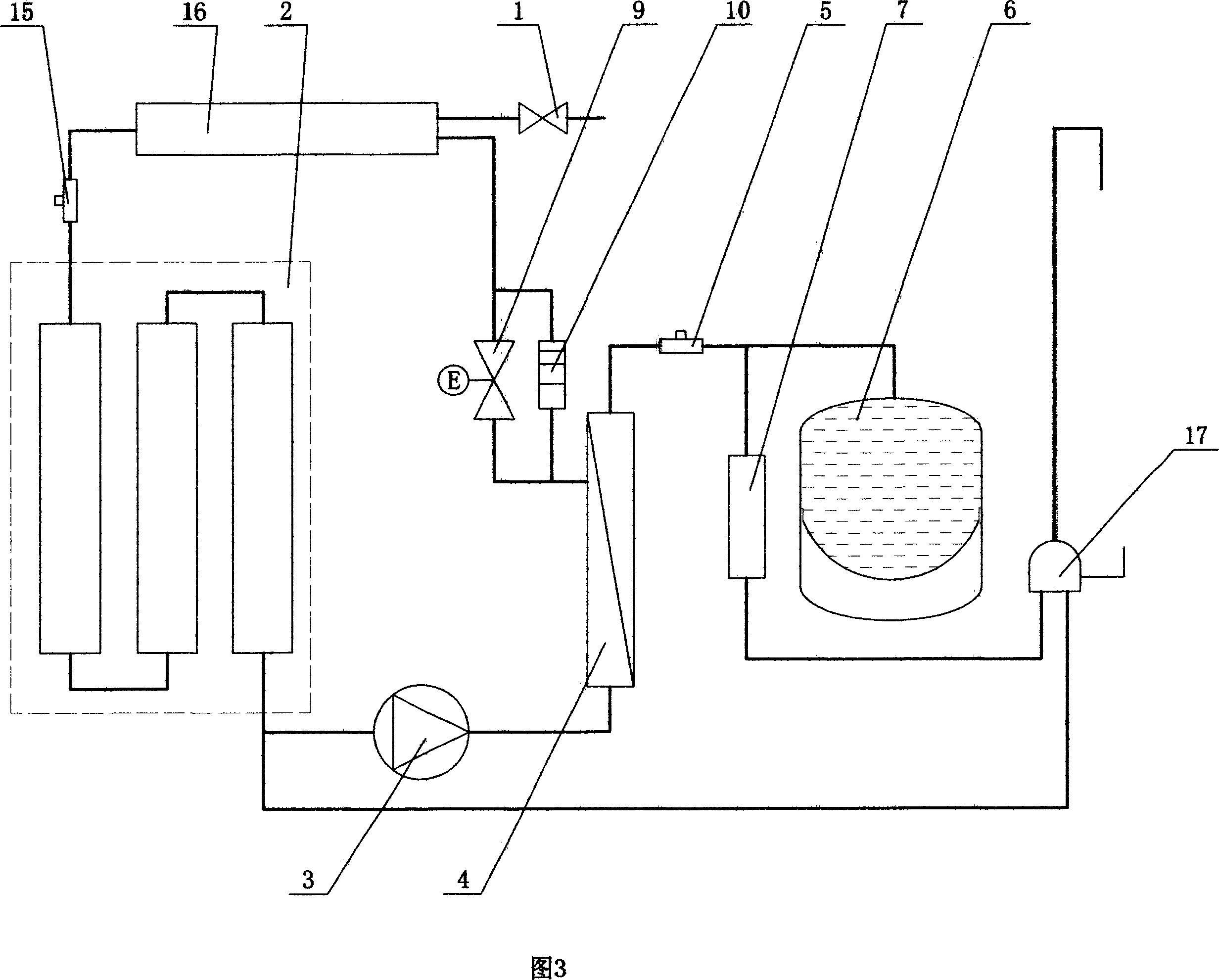

[0051] Embodiment one: in conjunction with Fig. 4, Fig. 5 and Fig. 6 shown, the water-saving and power-saving type reverse osmosis pure water machine of the present embodiment, it comprises pretreatment filter element (2), normal pressure intermediate water tank (32), high-pressure pump ( 3), reverse osmosis filter element (4) and normal pressure pure water tank (31); The inlet of described high-pressure pump (3) connects the filtering device (36) that can filter out particulate matter and suspended matter in water, then connects normal pressure intermediate water tank (32), its outlet connects the water inlet of reverse osmosis filter element (4); Receive the normal pressure intermediate water tank (32); the inlet of the described pretreatment filter element (2) is connected to tap water through the water inlet valve (1), and its outlet connects the normal pressure intermediate water tank (32); the described normal pressure intermediate water tank ( 32) is provided with a flo...

Embodiment 2

[0055] Embodiment two: in conjunction with shown in Fig. 7, in the present embodiment, normal pressure intermediate water tank (60) and normal pressure pure water tank (50) are mutually independent; Described normal pressure intermediate water tank (60) is provided with controllable water level A float valve (52), a water probe (54) that can detect whether there is water in it, a water quality probe (58) that can detect the TDS concentration in water, a water return interface (57), a water outlet interface (55), a water inlet interface (61 ) and air vent (59); said normal pressure pure water tank (50) is provided with inlet and outlet water interface (56), liquid level probe (53) and air vent (51); pure water outlet valve (49) is located at On the pipeline between the water inlet and outlet interface (56) and the water outlet of the reverse osmosis filter element; the mixed water outlet valve (62) is arranged on the pipeline between the water outlet interface (55) and the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com