Self-adhering water-proof coiled material and processing method thereof

A technology of self-adhesive waterproofing membrane and processing method, applied in chemical instruments and methods, other chemical processes, roofing using flexible materials, etc. , to achieve the effect of simple equipment, saving consumption and good pasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

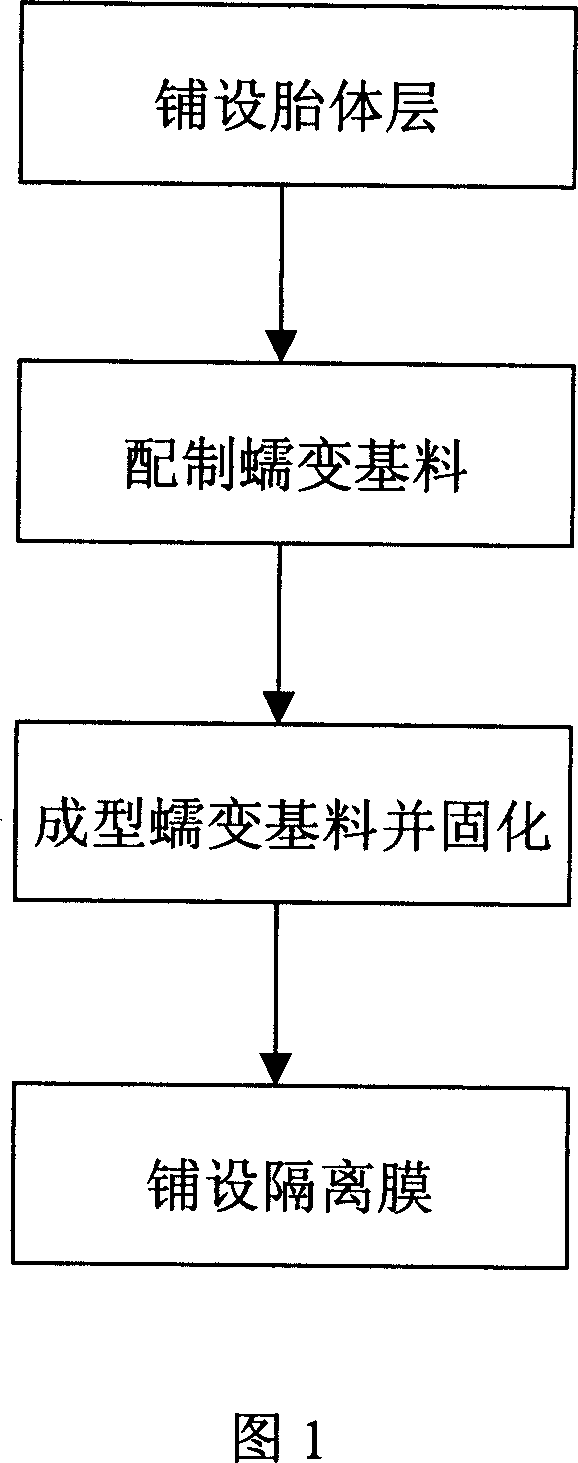

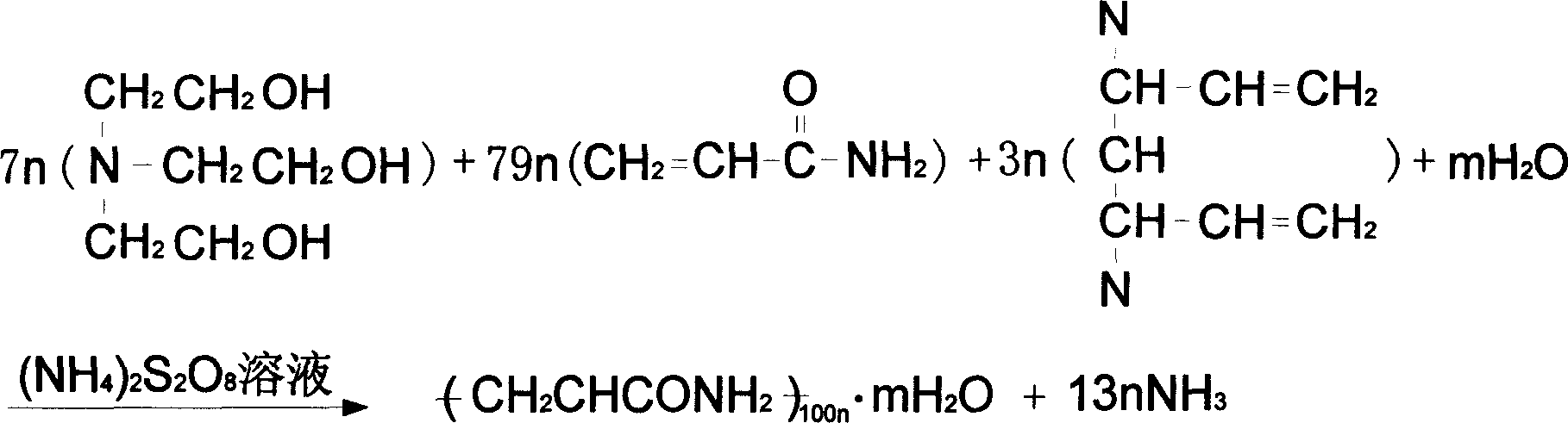

[0034] The present invention provides a self-adhesive waterproof membrane, which comprises a creeping base material and a carcass layer adhered to one side of the base material, wherein the creeping base material is formulated with the following formula (in parts by weight):

[0035] 50-100 parts of water

[0036] Acrylamide 15-40 parts

[0037] Bisacrylamide 0.02~0.5 part

[0038] Triethanolamine 0.5~30 parts

[0039] 0.1~1.0% ammonium persulfate aqueous solution 10~30 parts

[0040] The carcass layer is a non-directional non-woven fabric, of course, other various non-woven fabrics can also be used as the carcass layer.

[0041] List several concrete production formulas (parts by weight) of creep materials below:

[0042] recipe one

recipe two

Recipe three

Recipe four

water

60 copies

70 copies

50

100

20 copies

30 copies

15

40

Bisacrylamide

0.4 parts

0.05

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com