Method for detecting total foam protein content of beer barley and malt

A protein content and protein technology, applied in the preparation of test samples, color/spectral characteristic measurement, biological testing, etc., can solve the problems of inability to occupy a place and low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

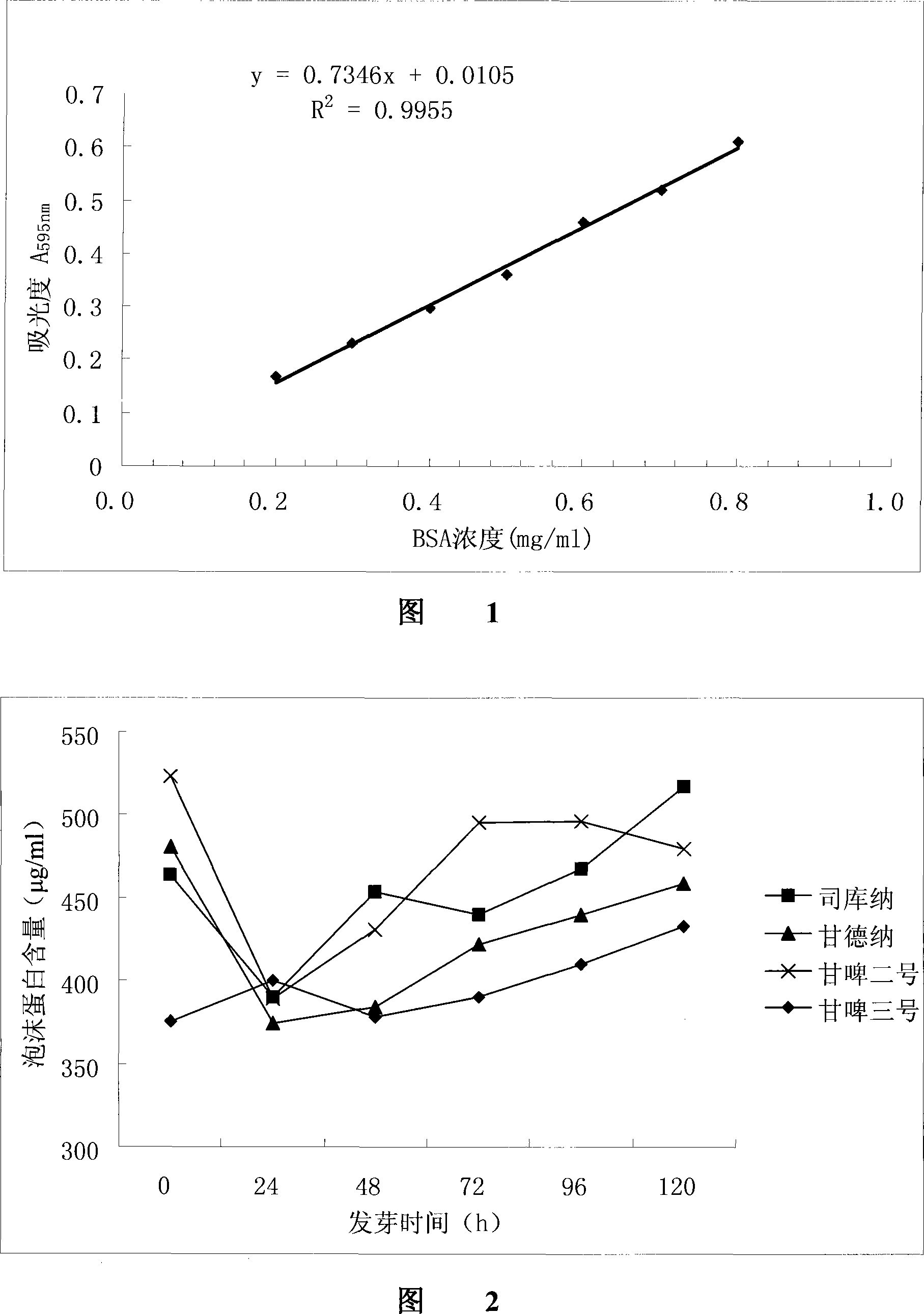

[0019] Embodiment 1. Determination of foam protein content in different varieties of barley and malt.

[0020] Four varieties of barley were germinated under the same conditions, namely Schooner (Australia), Gairdner (Canada), Ganpi No. 2 (Xinjiang), and Ganpi No. 3 (Inner Mongolia).

[0021] Germination conditions: pH 6.8 for soaking and spraying water, 16°C, dark room, ventilation.

[0022] Germination time: Soak wheat for 24 hours, germinate for 96 hours, a total of 120 hours.

[0023] Sampling is taken every 24 hours, and the original wheat sample is recorded as 0 hour of germination. There are a total of 24 samples, which are recorded as Schooner S0~S120, Gardner G0~G120, Gan Beer No. 2 X0~X120, Gan Beer No. 3 M0~M120.

[0024] Extraction buffer pH7.5, Tris-C150mmol L -1 , NaC110mmol·L -1 , DTT1mmol·L -1 , EDTA·2 Nalmmol·L -1 , and the balance is water.

[0025] Crush the above 24 samples, weigh 1g (dry weight after deduction of moisture), place in a plastic centri...

Embodiment 2

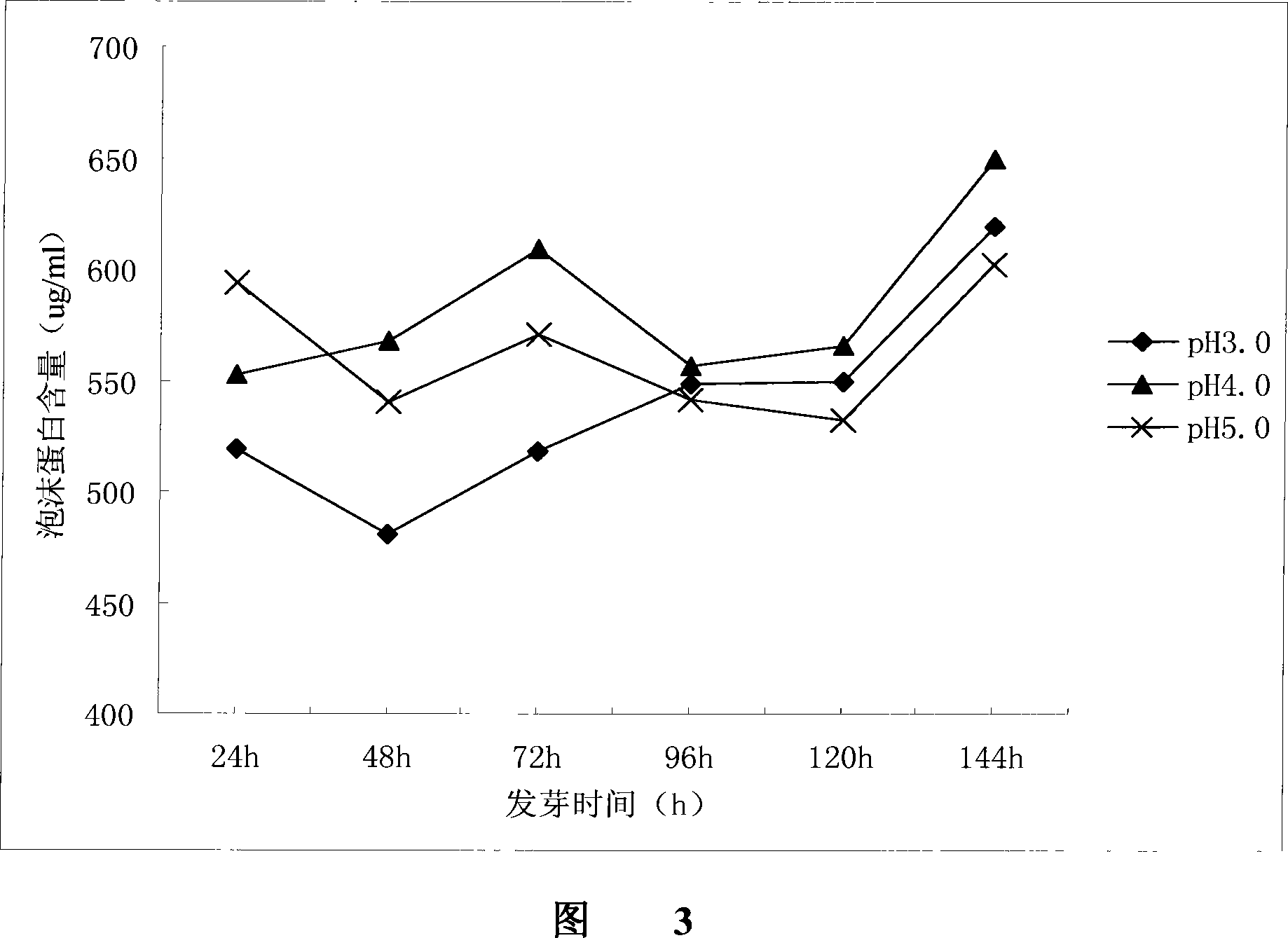

[0035] Embodiment 2, the determination of foam protein content in malt under different germination process conditions.

[0036] Barley variety: Gairdner (Canada).

[0037] Germination conditions: 16°C, dark room, ventilation and oxygen supply. The water used for soaking wheat and spraying is citric acid aqueous solution with pH 3.0, pH 4.0 and pH 5.0 respectively.

[0038] Germination time: Soak wheat for 48 hours, germinate for 96 hours, a total of 144 hours. Samples were taken every 24 hours, a total of 18 samples.

[0039] The extraction and determination methods are the same as in Example 1, and the bovine serum albumin (BSA) standard curve is the same as in Example 1. The results of the measurement are shown in Table 2.

[0040] According to the total foam protein content of each sample in Table 2, the content changes of total foam protein in each variety of barley during the germination process were drawn (Fig. 3).

[0041] Table 2 Total foam protein content in malt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com