Fe3O4 Au magnetic deposition film preparation method

A technology of fe3o4-au and a new method, which is applied in the field of preparing Fe3O4-Au magnetic deposition thin films, can solve the problems of limiting film material stability and biocompatibility, and achieve shortened reaction time, good biocompatibility and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach I

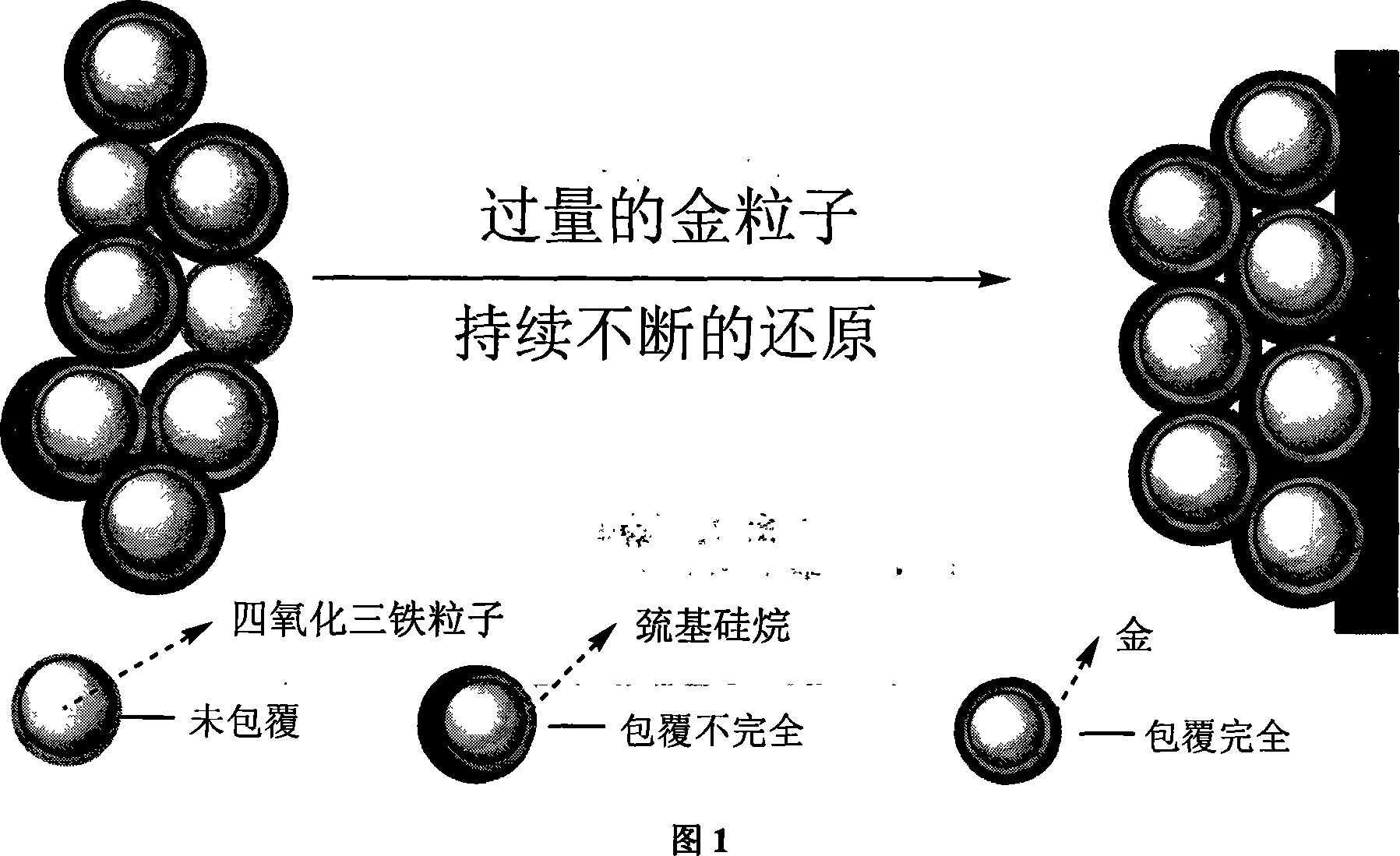

[0020] The present invention relates to a kind of preparation Fe 3 o 4 - A new method for the magnetic deposition of thin films of Au. Specifically as follows: 1) get 2gFeCl respectively 2 4H 2 O and 5.2 g FeCl 3 ·6H 2 O and 0.85 mL of concentrated hydrochloric acid of 12.1 mol / L were dissolved in 200 mL of H 2 O, ultrasonic deoxygenation, and then the above solution was added dropwise to 250mL, 0.75mol / L NaOH solution, all reactions were carried out at a temperature of 80°C, stirring, N 2 under protection. As the reaction progressed, a black precipitate appeared in the reaction solution. After the reaction, the obtained precipitate was separated from the reaction medium by using an external magnetic field, and washed three times with deionized water and twice with ethanol. Finally Fe 3 o 4 Nanoparticles were made into an ethanol solution with a concentration of 5g / L. 2) Dilute the above 25mL solution to 150mL with ethanol and 1mL water, in order to better disperse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com