Stainless steel plate integral burner

A stainless steel plate and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of complex structure, increased cost, and many production processes, and achieve simple manufacturing process, avoid deformation and damage, and fix strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

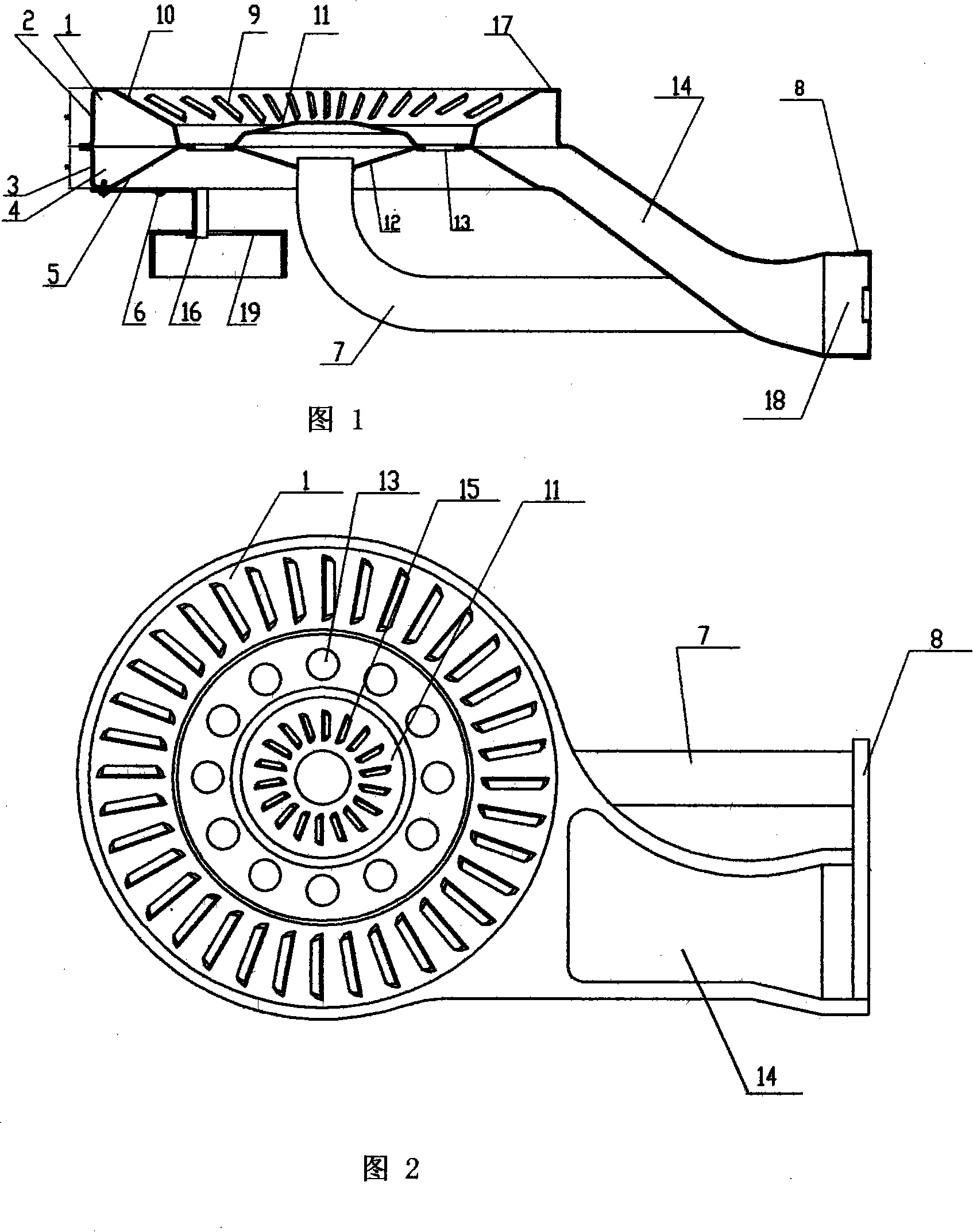

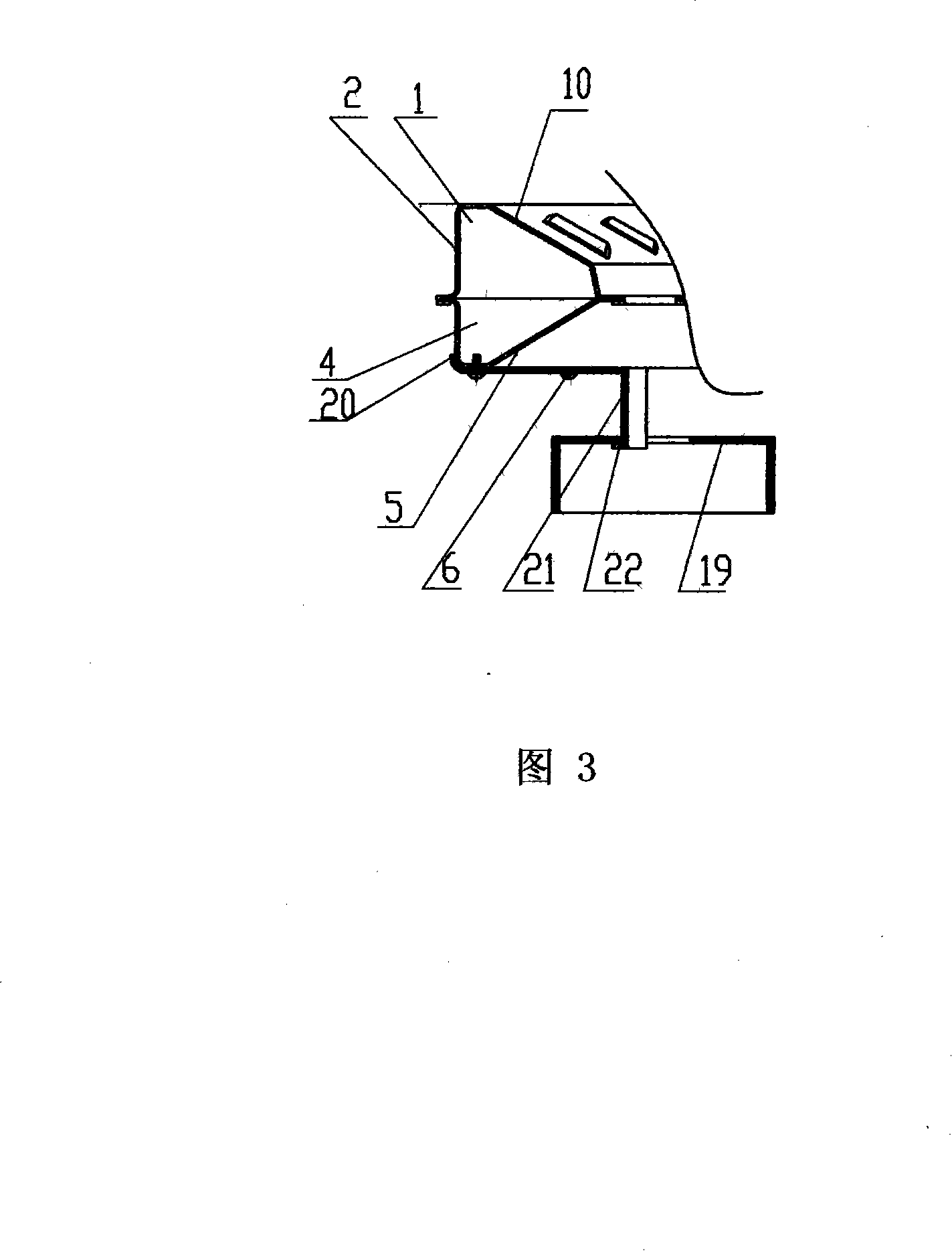

[0020] The specific implementation of the present invention will be further described below in conjunction with the embodiments given in the drawings.

[0021] As shown in Figures 1 and 2, the stainless steel plate integral burner according to the present invention includes a burner upper body 1 and a burner lower body 4, a main fire ejection tube 14, a central small fire ejection tube 7, and a burner upper body There is a convex cone-shaped conical ring with a long slit fire hole 9 on it, which is characterized in that the burner upper body 1 is a stamped and formed piece of stainless steel plate, and the outer ring has a long arc-shaped slit fire hole 9 The conical disc portion 10, the upper boss-shaped portion 11 with a long slit fire hole 15 in the center, and the annular transition portion with a vent 13 between the two, and the main lead extending from the conical disc portion The upper cover of the shoot tube 14, the riveted edge riveted with the lower body 4 of the burner,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com