Collagen produced accelerant, dressing material, and method for producing collagen

A technology for cosmetic materials and manufacturing methods, which is applied in the direction of cosmetic preparations, cosmetics, preparations for dressing, etc., and can solve the problems of promoting collagen production without polyphosphoric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0073] [Manufacturing example 1] Preparation of sodium polyphosphate

[0074] Sodium polyphosphates of various chain lengths were prepared as described below. (i) 200 g of food additive standard sodium hexamethylphosphate (manufactured by Taihei Chemical Industry Co., Ltd.) was dissolved in 1,000 ml of purified water, and 50 ml of 96% ethanol was slowly added thereto. (ii) The obtained solution was stirred well, left to stand at room temperature for 1 hour or more, and then centrifuged (10,000×g, 10 minutes, 25° C.) to separate the liquid into two layers. (iii) Take out the upper layer and move it to another container. (iv) The lower layer containing high-molecular-weight (long-chain) sodium polyphosphate is collected and stored as a fraction (fraction 1) containing long-chain sodium polyphosphate with the largest molecular weight.

[0075] (v) Further add 50 ml of ethanol to the upper layer that has just been separated and recovered by the operation of (iii). The operation...

Embodiment 1

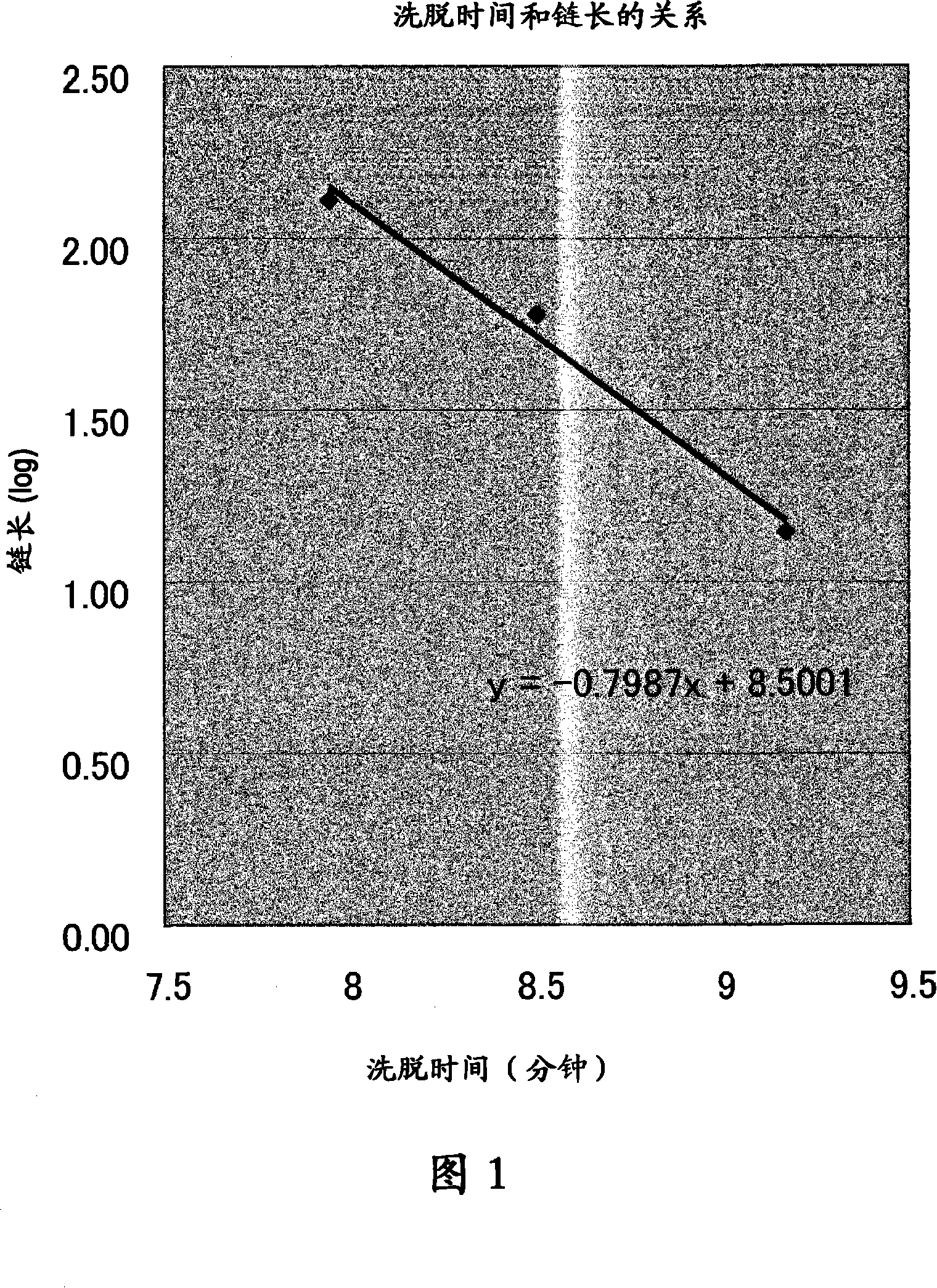

[0078] Determining the Average Molecular Weight and Molecular Weight Range of Sodium Polyphosphate

[0079] As a result of the above separation operation, each fraction was divided into three groups and mixed, and each group was made into long-chain sodium polyphosphate, medium-chain sodium polyphosphate, and short-chain sodium polyphosphate. The group of mixed fractions 1 and 2 is long-chain sodium polyphosphate, the group of mixed fractions 3-5 is medium-chain sodium polyphosphate, and the group of mixed remaining fractions 6-9 is short-chain sodium polyphosphate. Moreover, the group which mixed all the fractions 1-9 was made into the split sodium polyphosphate containing all molecular weights and having a large molecular weight distribution. The mixture of each of the above fractions was freeze-dried, and ethanol was completely removed to obtain sodium polyphosphate powders of each chain length. The average chain length and molecular weight distribution of each group were ...

Embodiment 2

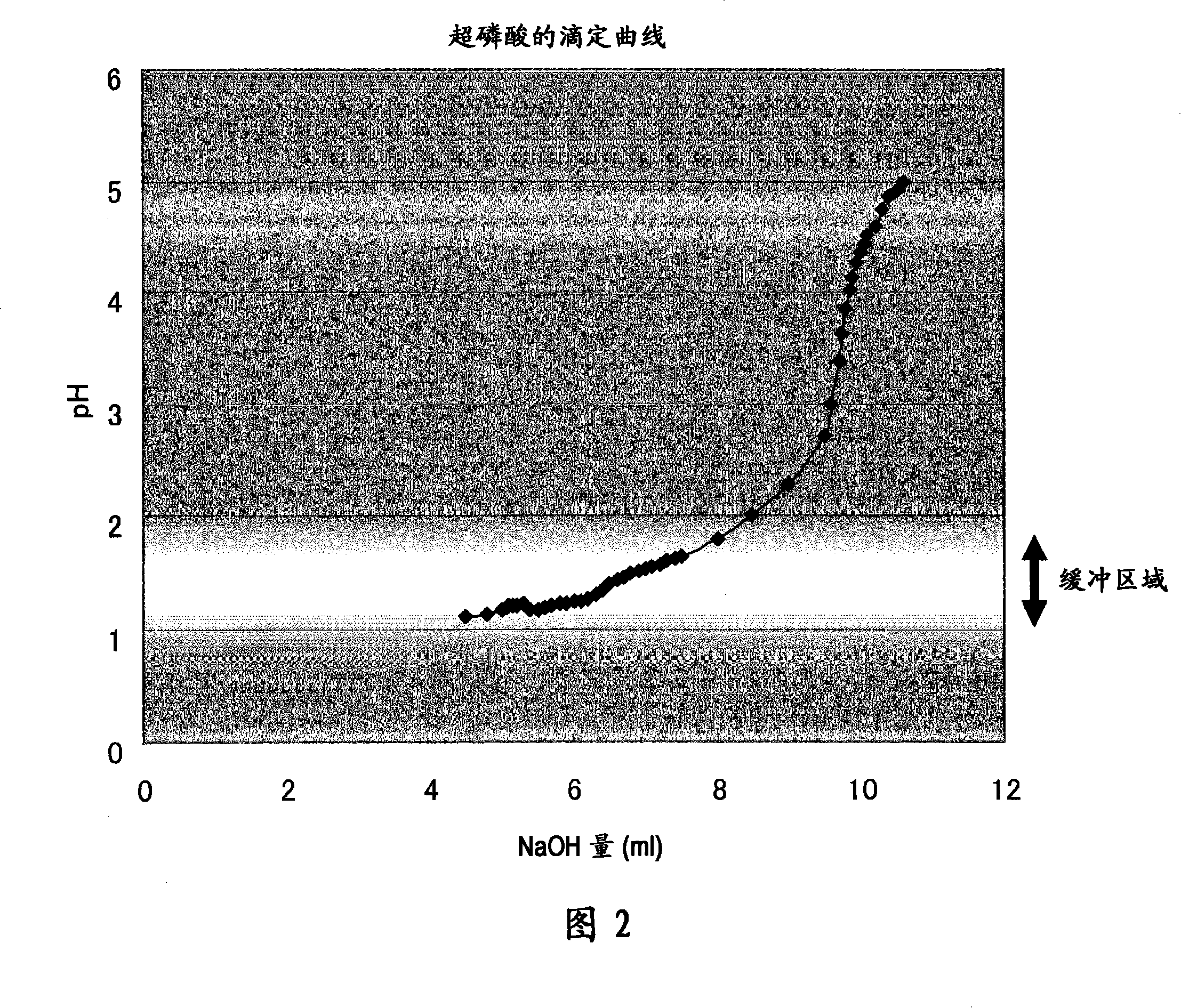

[0099] Confirmation of the properties of sodium superphosphate

[0100] Regarding the sodium superphosphate used in this example, it is known as its molecular characteristics that when it is made into an aqueous solution, it shows a strong acidity of pH 1 to 2, and when it is titrated with an alkaline solution such as sodium hydroxide, it becomes acidic at the above pH. The regions have pH buffered regions. Proceeding from this fact, the sodium superphosphate aqueous solution was titrated with the sodium hydroxide aqueous solution, and the pH change thereof was measured, as shown in FIG. 2 . As a result, buffering action was exhibited around pH 1 to 2, and it was confirmed that it had properties of sodium superphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com