Multi-relative position electrohydraulic scale servo system position control method

A technology of servo system and electro-hydraulic ratio, which is applied in manufacturing tools, presses, etc., can solve the problems of low precision of position control, non-adjustment of liquid flow, and temperature rise of hydraulic oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

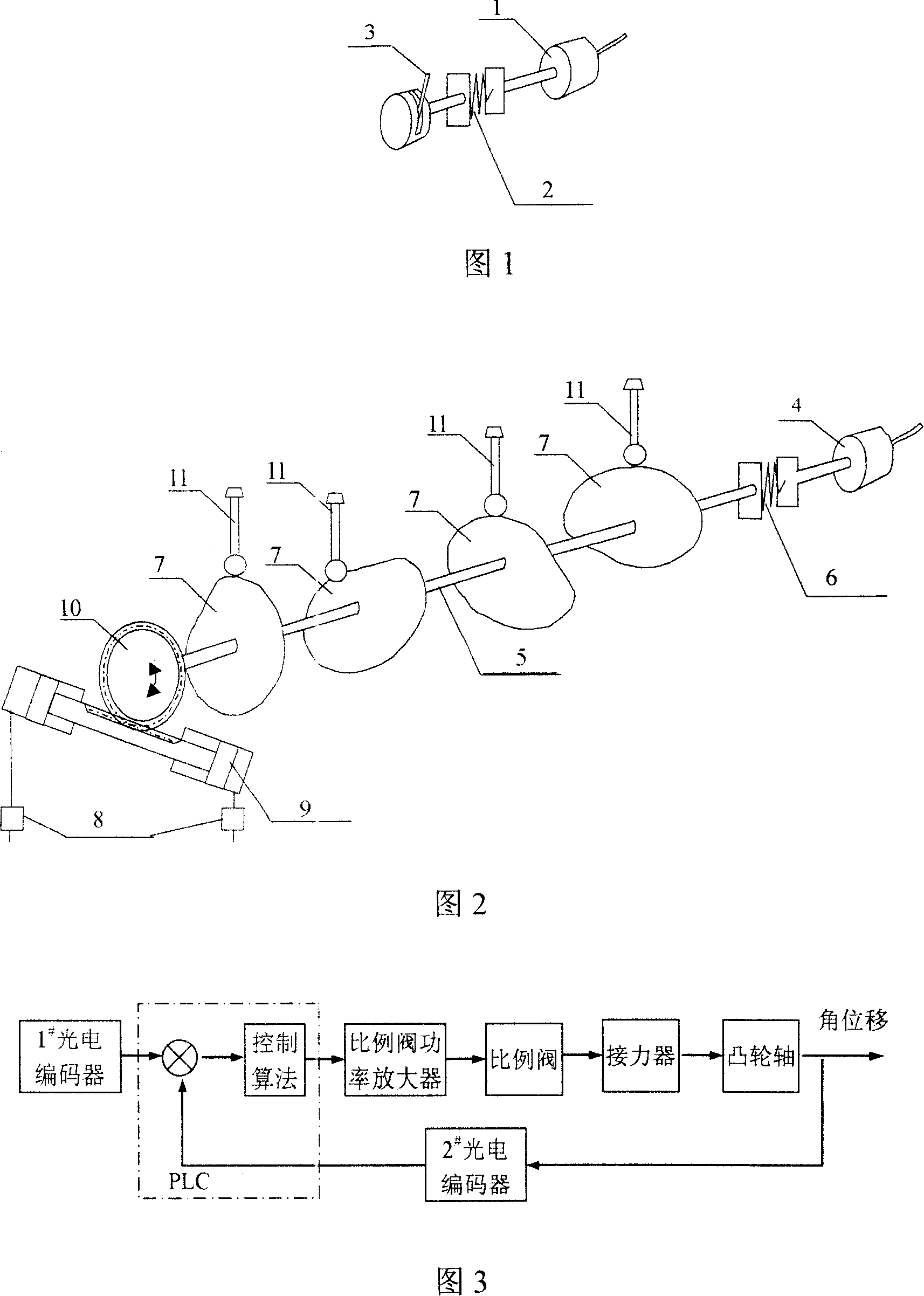

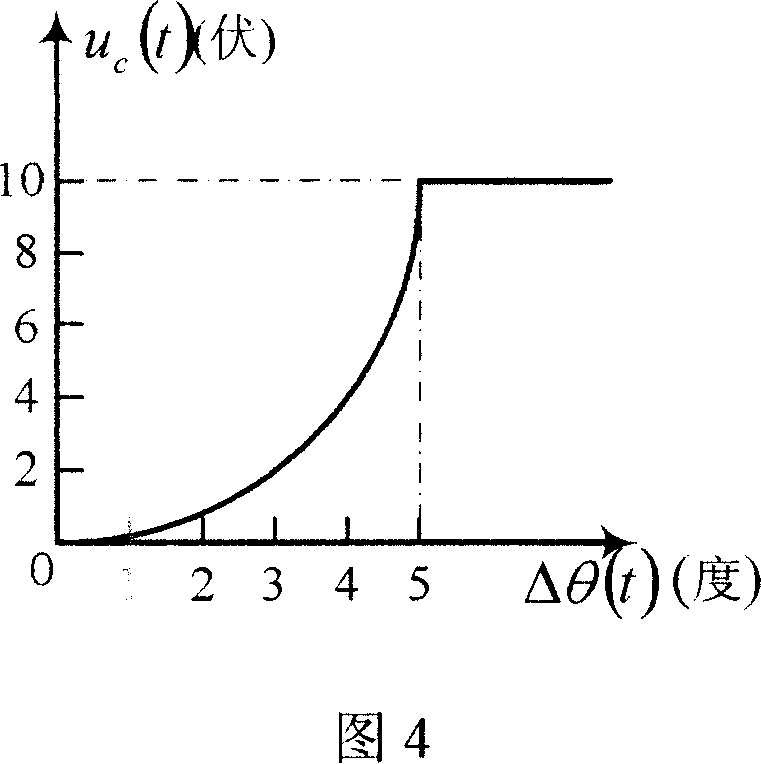

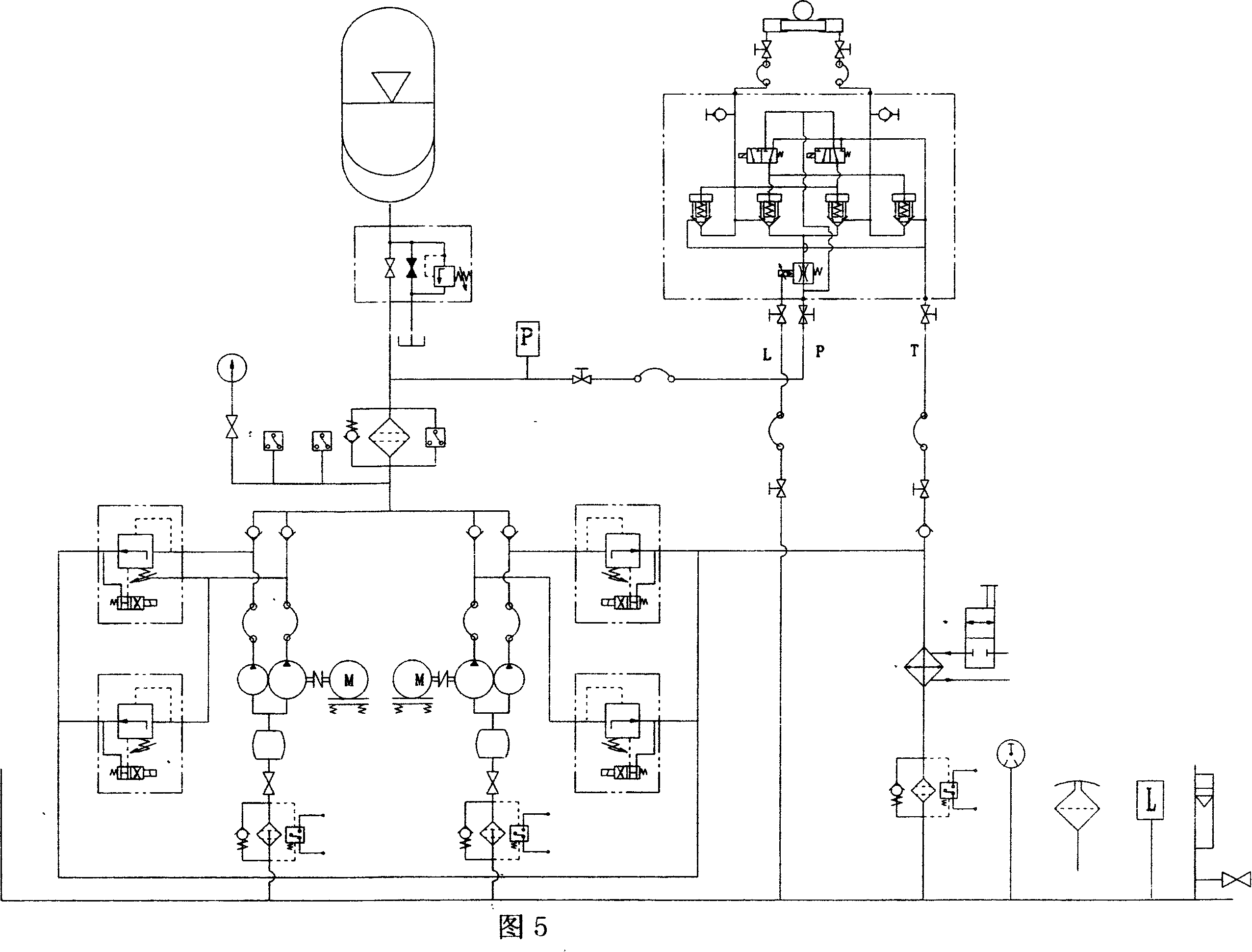

[0012] [Implementation mode] As shown in Figure 1 and 2, 1 # The photoelectric encoder 1 is connected with the rotating shaft of the operating handle 3 through an elastic coupling 2 . 2 # The photoelectric encoder 4 is installed on one end of the distributor shaft 5 and is connected with the distributor rotating shaft 5 through an elastic coupling 6 . Multiple cams 7 are installed on the distributor shaft 5. The relative position of each cam depends on the needs of multiple working conditions of the system and is related to the angle of the shaft. The rotation angle of the cam shaft is controlled by a digital electro-hydraulic proportional servo system 8. The hydraulic oil flow rate and the moving speed of the hydraulic cylinder piston rod 9 are described by the following formula:

[0013] Q=k·V

[0014] In the above formula, Q is the hydraulic oil flow rate, k is the proportional coefficient, and V is the moving speed of the hydraulic piston rod 9 . Controlling the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com