Layered mesoporous birnessite manganese dioxide cellular nano ball, preparing method and use of the same

A birnessite and honeycomb technology is applied in the field of layered mesoporous birnessite-type MnO2 honeycomb nanospheres and their preparation, and achieves the effects of high structural stability, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

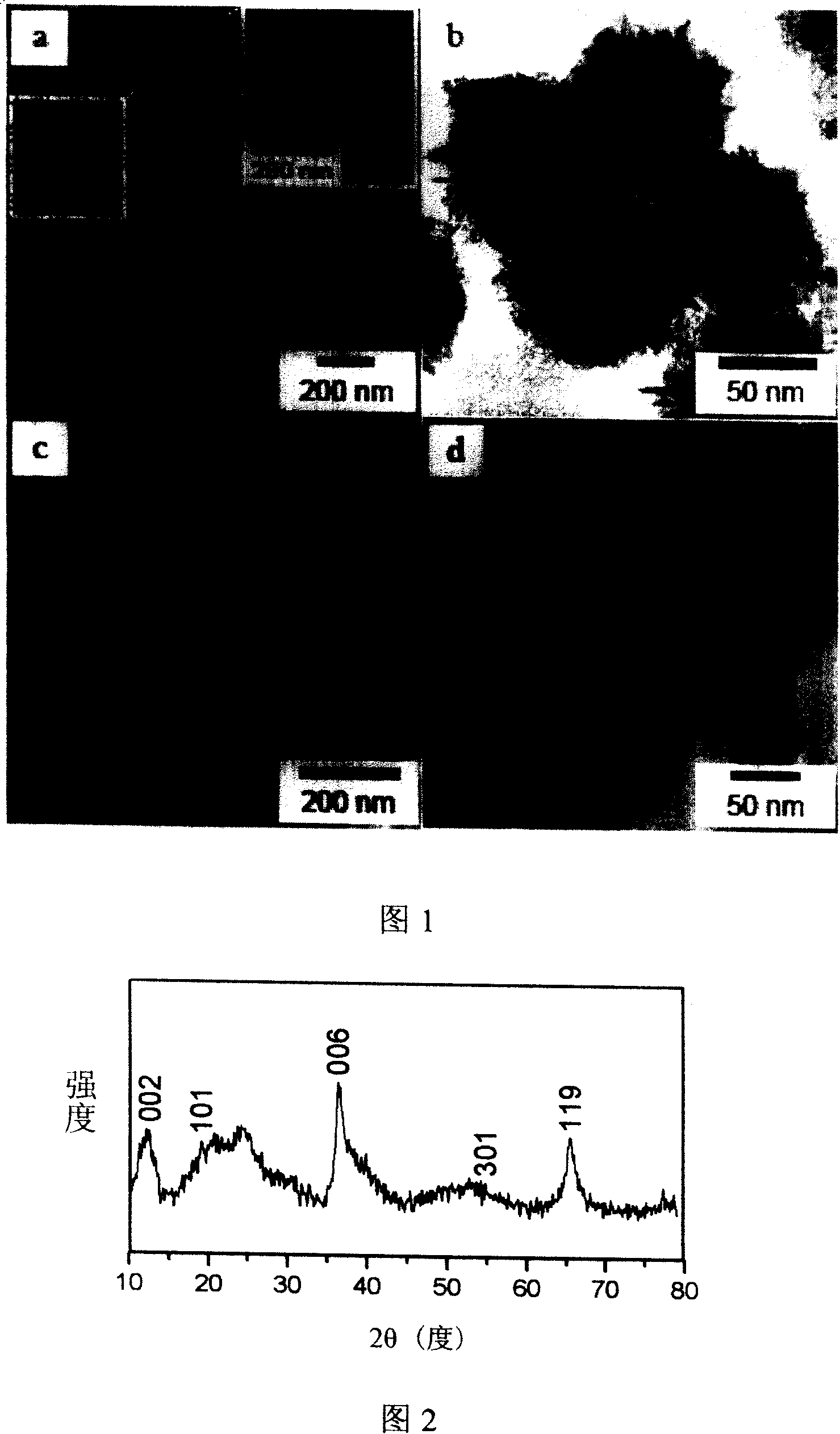

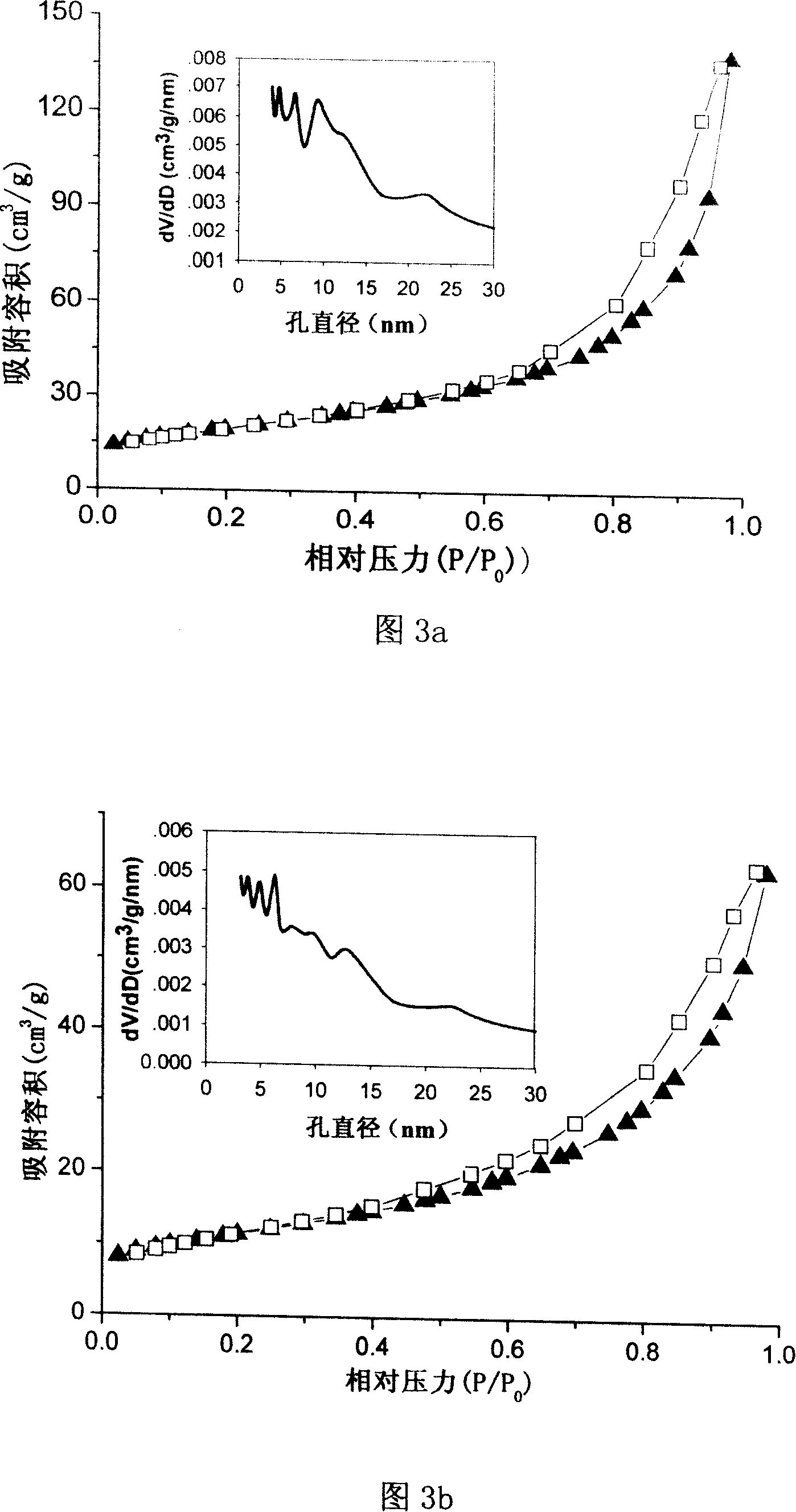

[0031] Take a certain amount of potassium permanganate with a purity of not less than 99.5% and dissolve it in 40-60 mL of distilled water, stir at room temperature for 15-30 minutes, and add 1 mL of oleic acid dropwise (the density of oleic acid is 0.891-0.899 g / mL, and the saponification value is not less than 3. The acid value is 190-200), the molar ratio of potassium permanganate / oleic acid is 1 / 10-3 / 10, and the stirring reaction is continued for not less than 5 hours. After reacting for a certain period of time until solid precipitates appear, separate at 4000 rpm for 10 to 15 minutes, then wash the sample with distilled water and ethanol, and repeat 3 to 5 times. The final sample was vacuum-dried at 50-70 degrees Celsius for more than 10 hours, and the obtained dark brown layered mesoporous birnessite-type MnO 2 The honeycomb nanospheres are shown in Figures 1a and 1b. Take a small amount of dried sample and redisperse it in ethanol, ultrasonically disperse it under 120...

Embodiment 2

[0035] Prepare layered mesoporous birnessite type MnO according to the method of Example 1 2 Honeycomb hollow nanosphere structure. Take a certain amount of potassium permanganate with a purity of not less than 99.5% and dissolve it in 40-60 mL of distilled water, stir at room temperature for 15-30 minutes, and add 1 mL of oleic acid dropwise (the density of oleic acid is 0.891-0.899 g / mL, and the saponification value is not less than 3. The acid value is 190-200), the molar ratio of potassium permanganate / oleic acid is 1-2, and the stirring reaction is continued for not less than 5 hours. After reacting for a certain period of time, separate at 4000 r / min for 10-15 minutes, then wash the sample with distilled water and ethanol, and repeat 3-5 times. The final prepared samples were dispersed and dried in vacuum at 50-70 degrees Celsius for more than 10 hours, and the obtained dark brown layered mesoporous birnessite-type MnO 2 The honeycomb hollow nanospheres are shown in Fi...

Embodiment 3

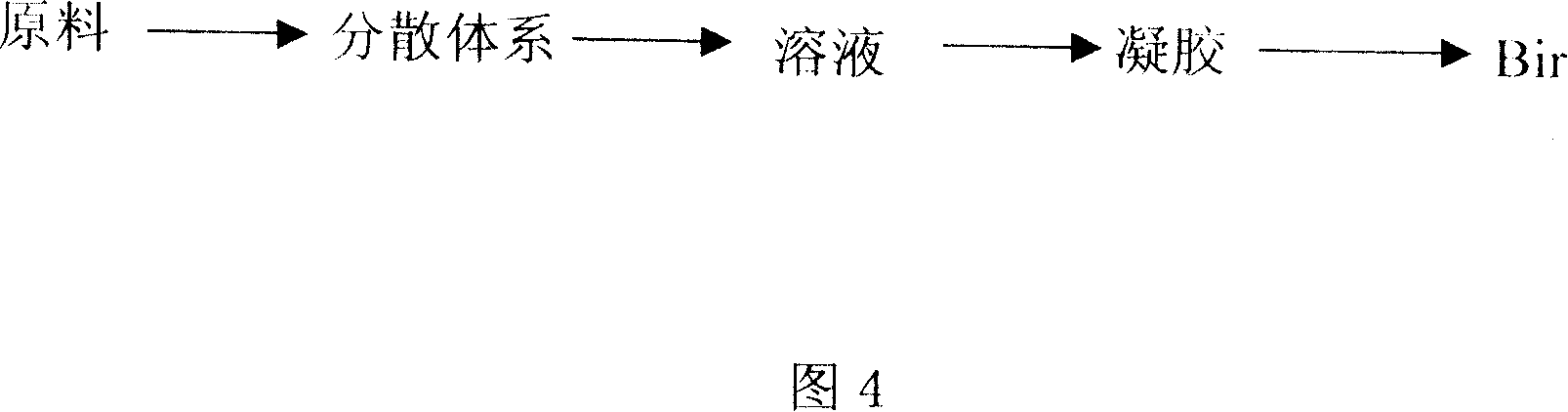

[0038] Get the layered mesoporous birnessite type MnO obtained in embodiment 1 and 2 2 Honeycomb nanospheres and honeycomb hollow nanospheres were degassed at 150 degrees Celsius, and their nitrogen adsorption at -196 degrees Celsius was measured on a nitrogen adsorption-desorption analyzer (Quantachrome NOVA 4200e, Quanta, USA) properties, the experimental results are shown in the curve in Figure 3, which shows that the obtained layered mesoporous birnessite-type MnO 2 Honeycomb nanospheres and honeycomb hollow nanospheres have good gas adsorption properties. Figure 3a shows layered mesoporous birnessite-type MnO 2 Nitrogen adsorption-desorption isotherms and pore size distribution curves of honeycomb nanospheres; Figure 3b shows the layered mesoporous birnessite-type MnO 2 Nitrogen adsorption-desorption isotherms and pore size distribution curves of honeycomb hollow nanospheres. The isotherm has a hysteresis loop, indicating that the as-prepared layered mesoporous birness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com