Technique of controlling and cooling hot-rolled seamless tube online

A seamless steel pipe and controlled cooling technology, which is applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as hot-rolled seamless steel pipes that have not been found, and achieve easier control of cooling effect, simplified process, and better cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

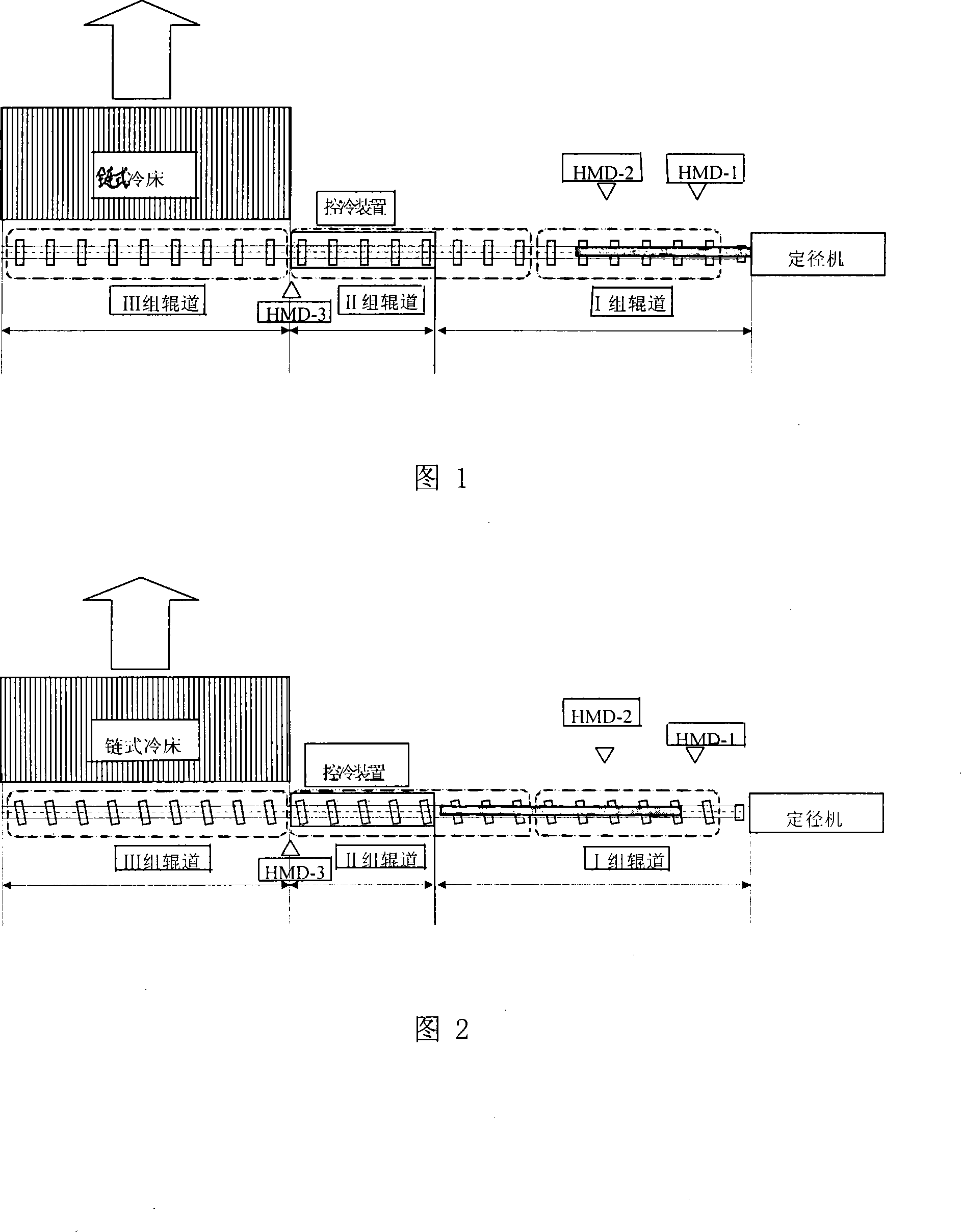

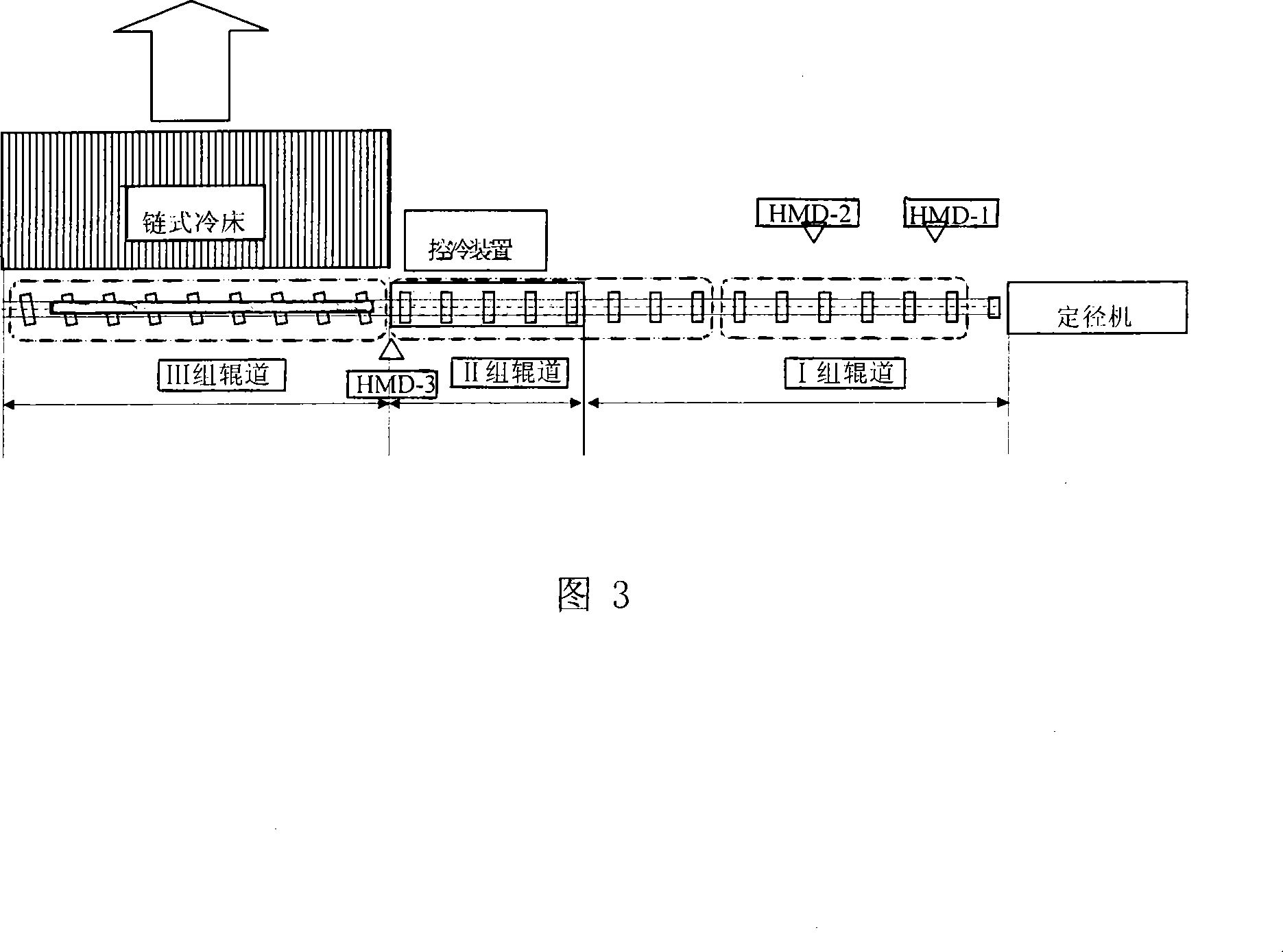

Image

Examples

Embodiment

[0036] In the early stage of hot test, the batch hot test was mainly based on equipment adaptability adjustment. Three specifications of ∮140×13mm, ∮168×16mm, and ∮180×22mm were tested successively. The steel types were 20# and 45#, and the cooling device was controlled. Choose to use mist cooling.

[0037] It can be seen from the record curve that the final rolling temperature after sizing is generally in the range of 950°C to 980°C, the temperature after controlled cooling is generally 680°C to 780°C according to the wall thickness of the pipe diameter, and the temperature drop is generally in the range of 950°C to 980°C. Between 200°C and 270°C. The temperature drop value varies with the wall thickness of the steel pipe. The thinner the pipe wall, the greater the temperature drop value, and the maximum value is around 270°C; the thicker the pipe wall, the slower the temperature drop value, and the minimum value is around 200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com