Heat-proof polylactic acid blend and preparation method thereof

A technology of polylactic acid and blends, which is applied in the field of polymer materials, can solve the problems of inability to meet heat resistance requirements, non-biodegradable, and limited improvement range, and achieve low cost, excellent mechanical properties, and good heat resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

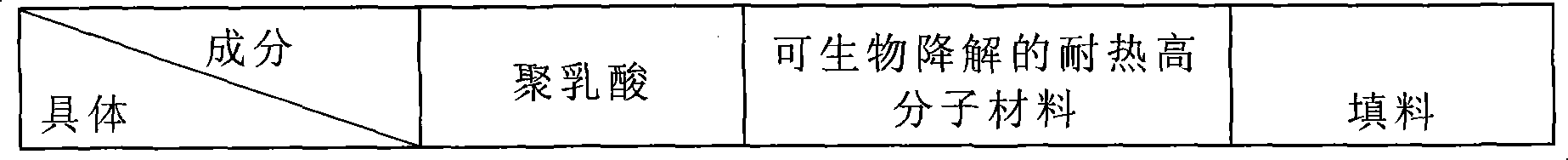

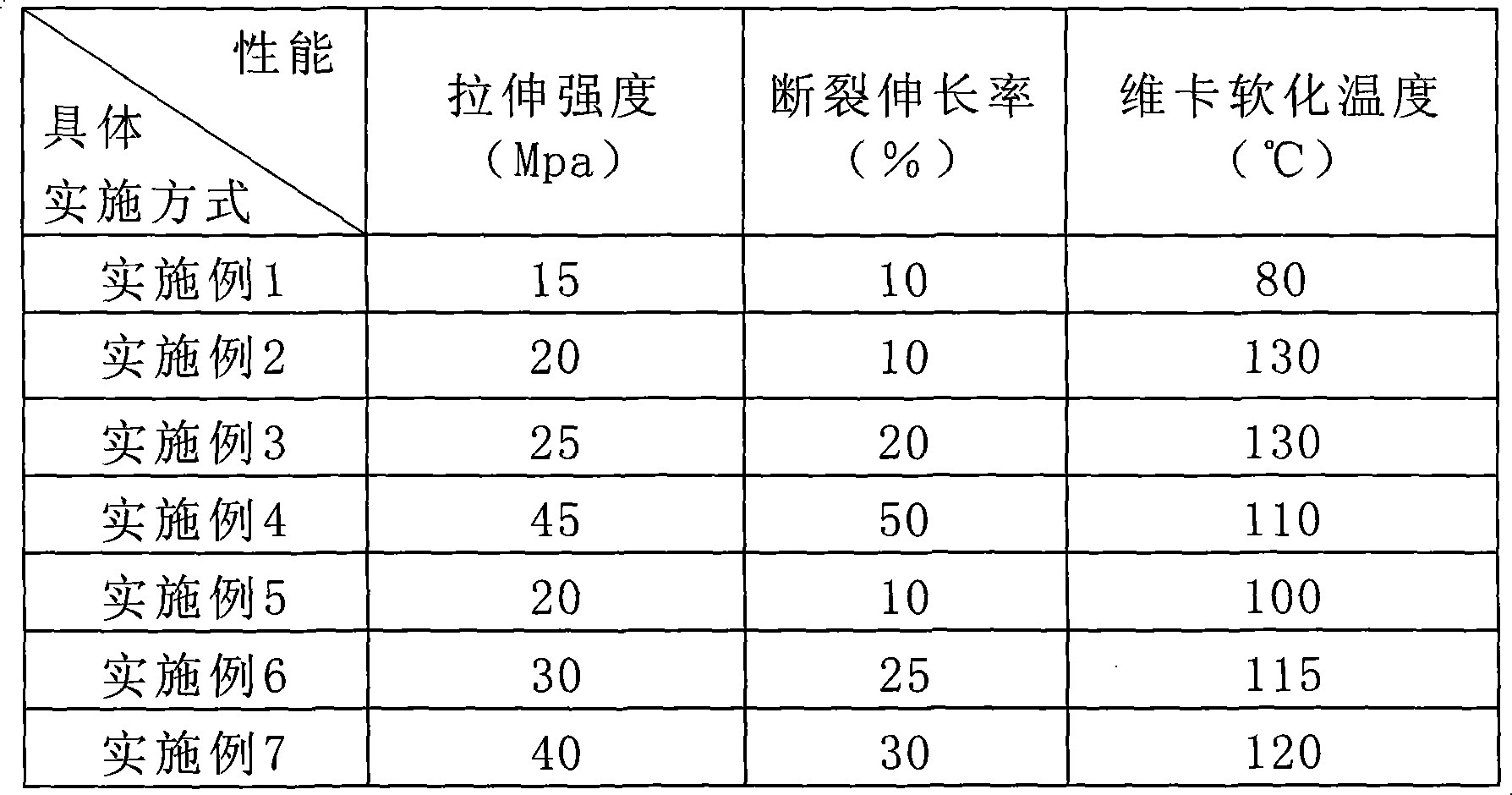

Embodiment 1

[0036] A, mixing: mix according to the composition of the weight portion of embodiment 1 in table 1, put into high-speed mixer after mixing and stir evenly;

[0037] B, internal mixing: put the above-mentioned blended ingredients into an internal mixer for internal mixing, wherein the internal mixing temperature is 150°C, and the internal mixing time is 20 minutes;

[0038] C. Hot press forming: hot pressing the above-mentioned resin after banburying at a temperature of 150° C. and a pressure of 15 MPa to obtain a sheet with a thickness of 1.0 mm;

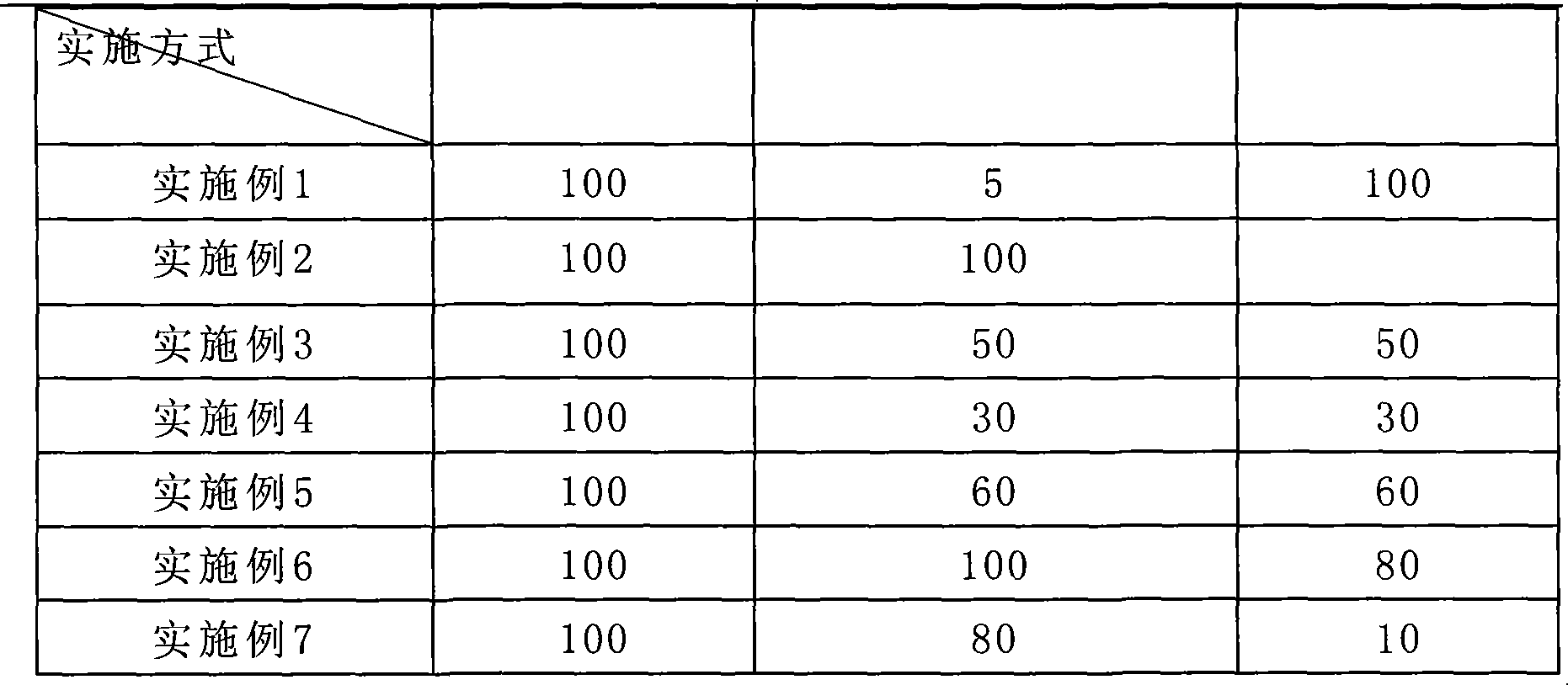

[0039] D. Isothermal crystallization: The heat-resistant polylactic acid blend was obtained after isothermally crystallizing the above-mentioned hot-pressed sheet at a temperature of 60°C for 5 minutes. The thermal properties are shown in Table 2.

Embodiment 2

[0041] A, mixing: mix according to the composition of the weight portion of embodiment 2 in table 1, put into high-speed mixer after mixing and stir evenly;

[0042] B, internal mixing: put the above-mentioned blended ingredients into an internal mixer for internal mixing, wherein the internal mixing temperature is 170°C, and the internal mixing time is 10 minutes;

[0043] C. Hot press molding: hot press molding the above-mentioned resin after banburying at a temperature of 180° C. and a pressure of 10 MPa to obtain a sheet with a thickness of 1.0 mm;

[0044] D. Isothermal crystallization: The heat-resistant polylactic acid blend was obtained after isothermally crystallizing the above-mentioned hot-pressed sheet at a temperature of 90°C for 70 minutes. The mechanical properties and resistance The thermal properties are shown in Table 2.

Embodiment 3

[0046] A, mixing: mix according to the composition of the weight portion of embodiment 3 in table 1, put into high-speed mixer after mixing and stir evenly;

[0047] B, internal mixing: put the above-mentioned blended ingredients into an internal mixer for internal mixing, wherein the internal mixing temperature is 190°C, and the internal mixing time is 5 minutes;

[0048] C. Hot press molding: hot press molding the above-mentioned resin after banburying at a temperature of 200° C. and a pressure of 8 MPa to obtain a sheet with a thickness of 1.0 mm;

[0049] D. Isothermal crystallization: The heat-resistant polylactic acid blend was obtained after isothermal crystallization of the above-mentioned hot-pressed sheet at a temperature of 120°C for 120 minutes. The thermal properties are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com