Coal gas naphthalene-purifying waste diesel reclaiming technique

A process method and technology of waste diesel oil, which is applied in the petroleum industry, combustible gas purification, refining by centrifugal force, etc., can solve problems such as lowering temperature, lowering diesel quality, and increasing fuel consumption, so as to facilitate sales and use, and solve storage and sales Difficulty, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

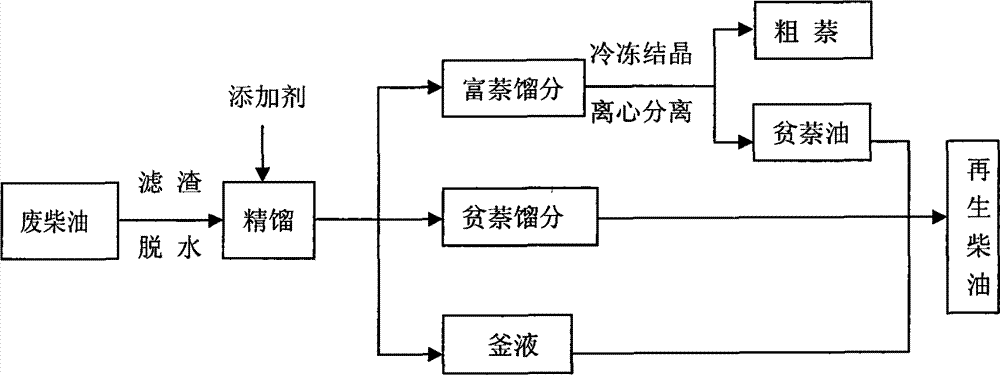

[0017] The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The main equipment used for separation is packed rectification tower, frozen crystallizer and centrifuge.

[0019] Add an aromatic compound (such as benzene or anthracene) to the naphthalene-washed waste diesel oil with a naphthalene content of 3% to 4% after filtering the residue and dehydrating it. This aromatic compound additive can change the naphthalene and other components in the waste diesel oil. The intermolecular force between them increases its relative volatility, and the dosage of the additive accounts for about 3% of the naphthalene content in the waste diesel. The waste diesel oil containing additives is sent to the packed tower for batch rectification.

[0020] After a period of total reflux operation, the fixed operation reflux ratio starts to collect the overhead fraction in sections. The overhead fraction is divided into two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com