Alignment apparatus, alignment method and imagery quality detecting method

A technology for alignment devices and detectors, which is applied to exposure devices, optics, instruments, etc. in photolithography, and can solve the problems of high manufacturing and configuration precision requirements for mirrors and lenses, high energy requirements for alignment lighting sources, and alignment device structures. Complicated problems, to achieve the effect of improving system work efficiency, reducing motion stroke, and optimizing alignment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

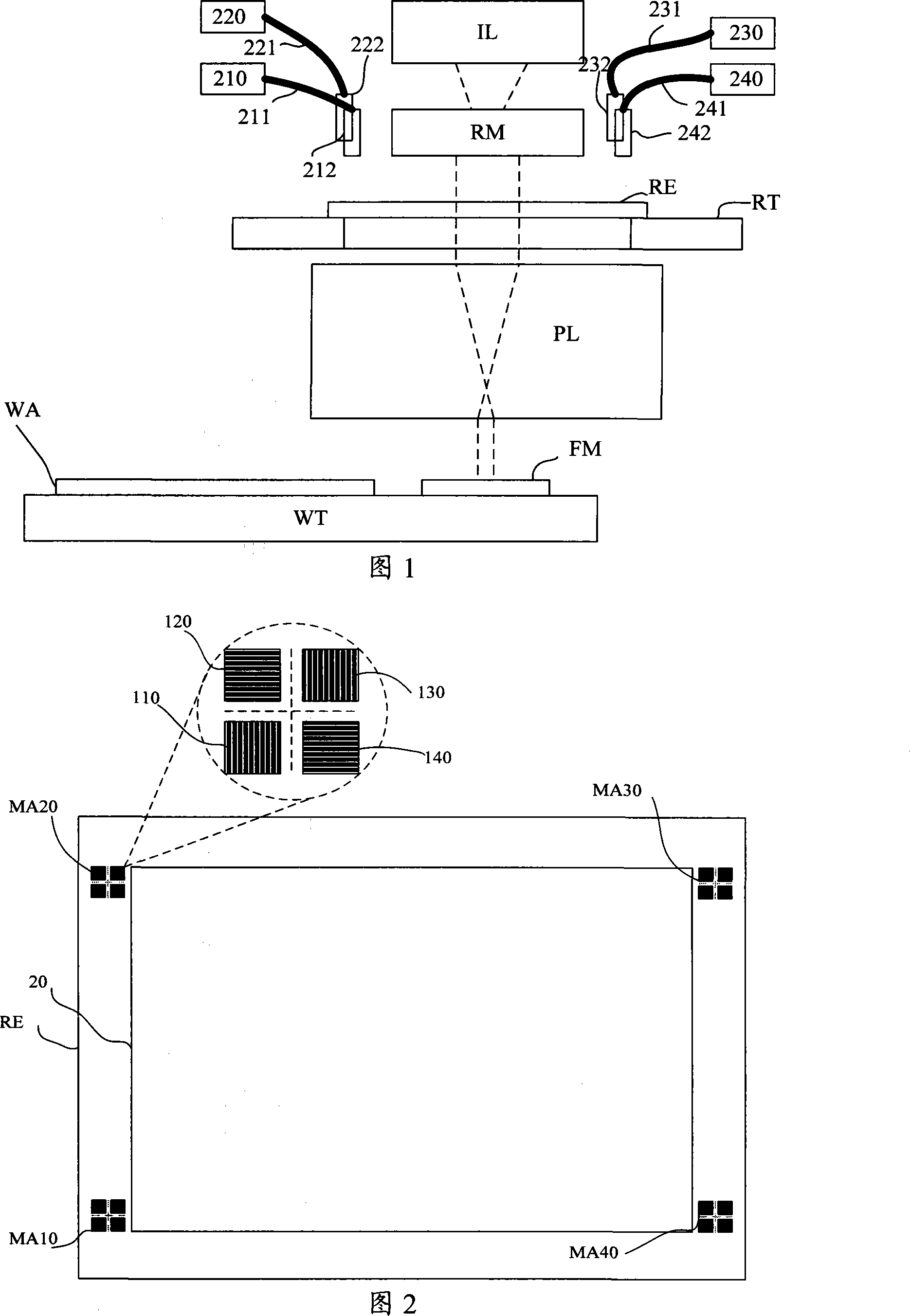

[0051] Figure 1 shows a schematic structural diagram of the alignment system of a lithography machine for mask and reference plate alignment, the alignment system includes an alignment light source and illumination system, mask RE, mask table RT, projection objective lens PL and settings The reference plate FM and the substrate WA on the workpiece table, the mask and the reference plate are respectively placed on both sides of the projection objective lens PL, the mask table can drive the mask to move, and the workpiece table can drive the reference plate and silicon wafer to move, aligning the lighting system It is located above the mask mark and is used to illuminate the mask mark. The alignment illumination light emitted by the alignment illumination system has a wavelength of 633nm or its wavelength is the same as that of the exposure lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com