Method for manufacturing cable for military industry equipment

A technology of military equipment and cables, which is applied in the direction of cable/conductor manufacturing, insulated cables, and conductor/cable insulation, etc. It can solve problems such as equipment failure, large temperature variation, and halogen generation, so as to ensure real-time performance and accuracy. Reduce the effect of signal attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

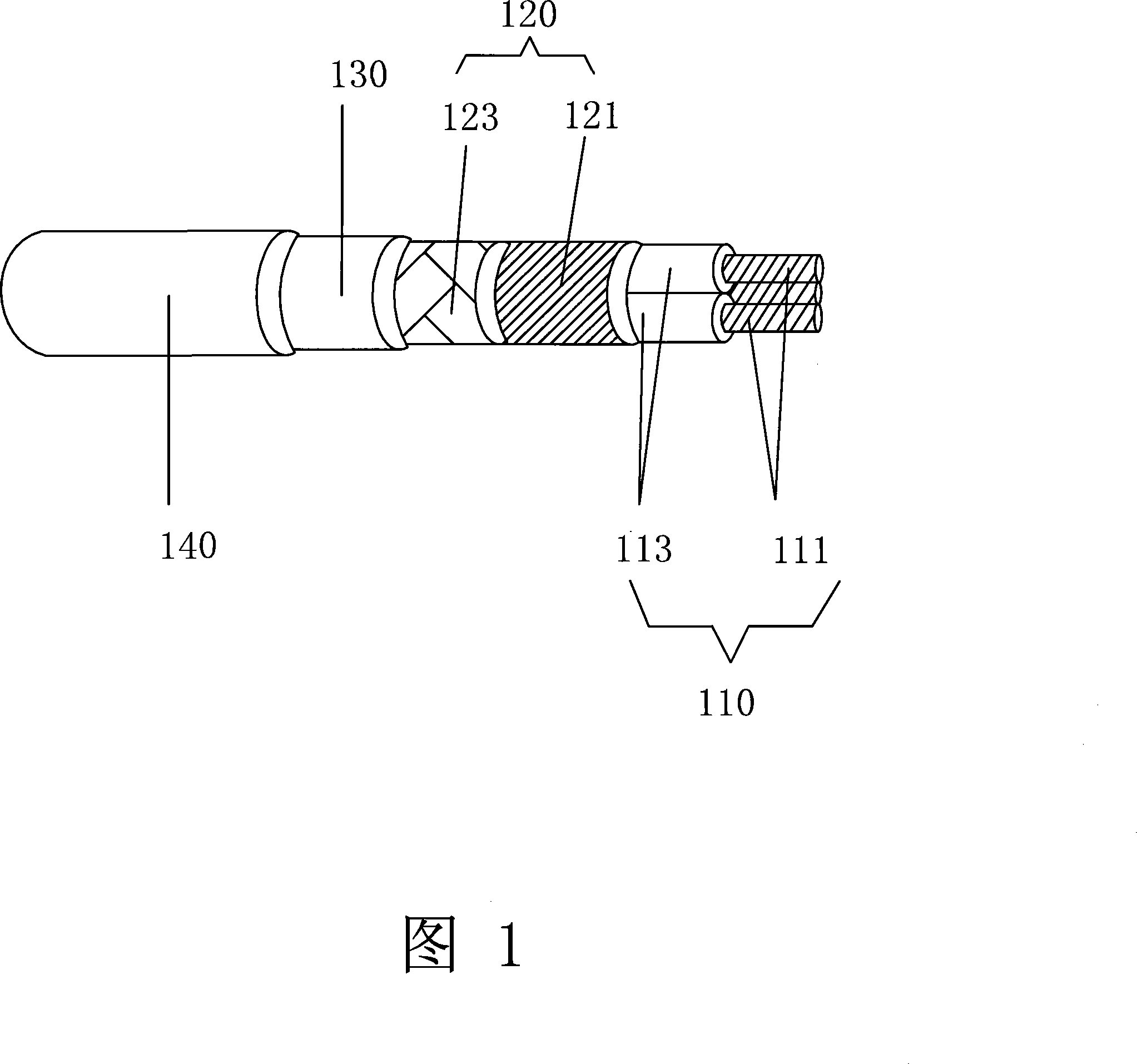

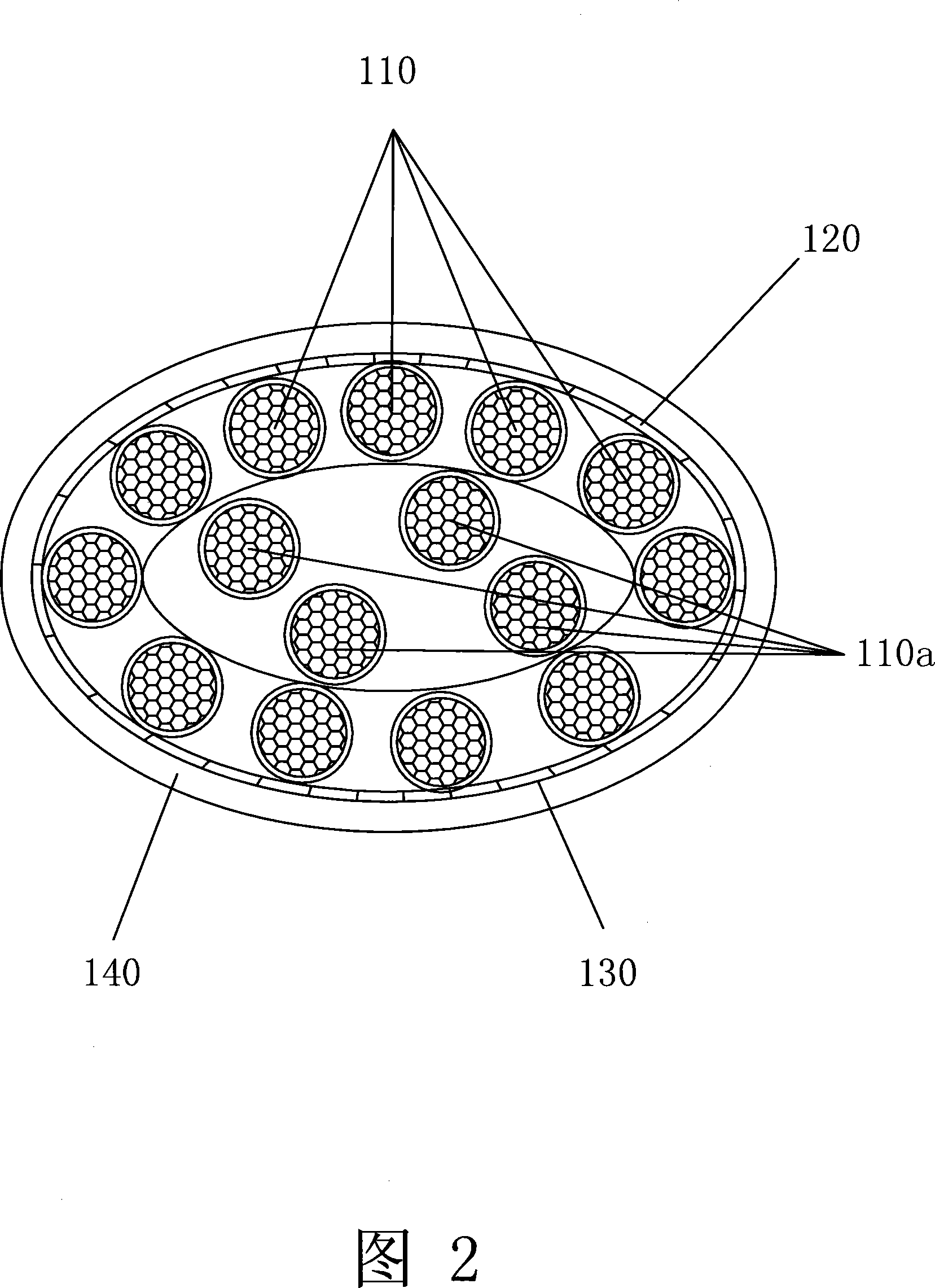

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention aims to provide a method for manufacturing a superconducting cable for military equipment. The cable manufactured by the method has fast signal transmission, environmental protection, cold resistance, ultraviolet resistance and good shielding effect. Harsh environment and ensure communication quality, meet several main conditions of cables for military equipment.

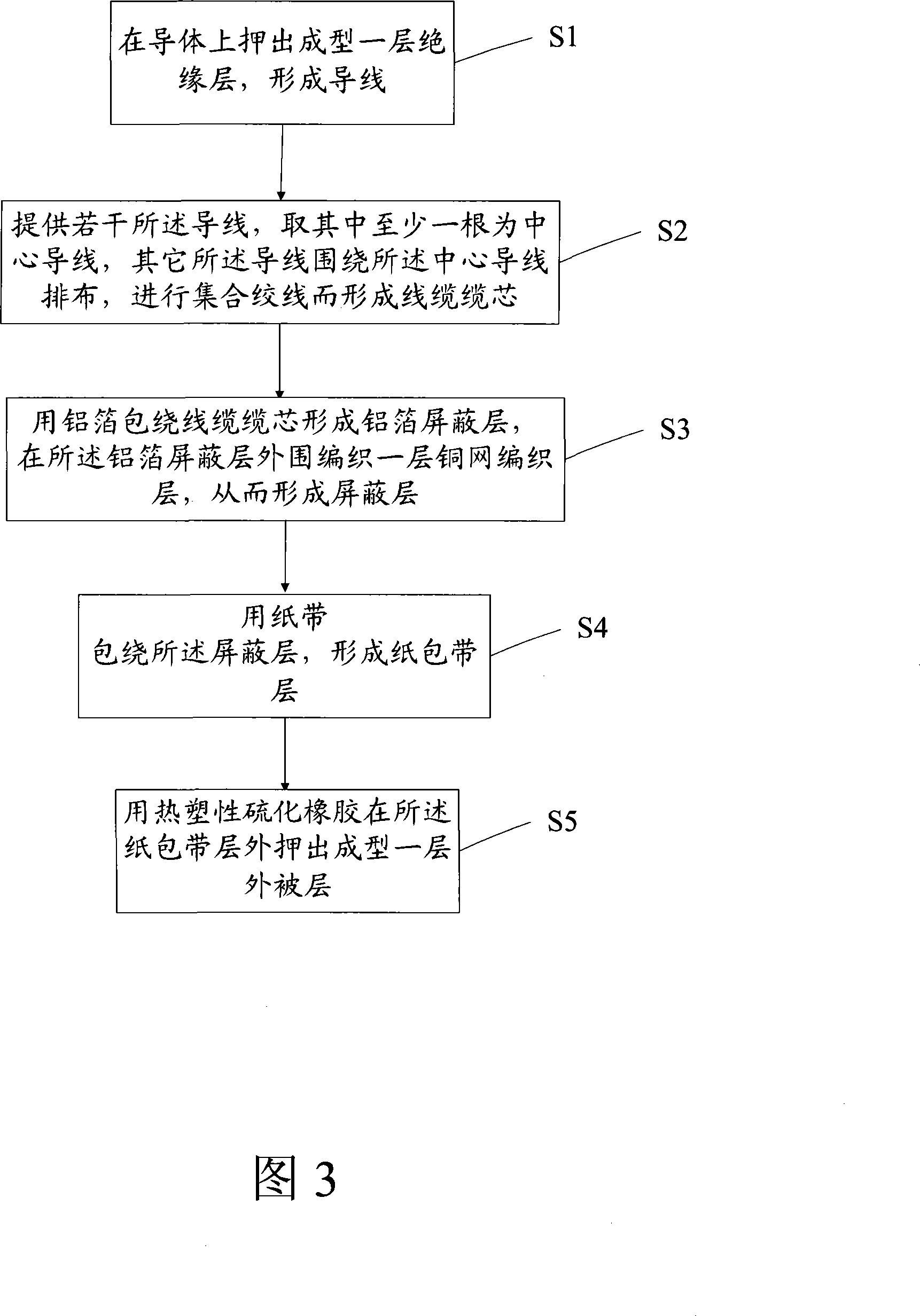

[0019] Fig. 3 is a flow chart of the method for manufacturing cables for military equipment according to the present invention. As shown in the figure, the method includes the following steps: (S1) extruding and forming a layer of insulating layer on the conductor to form a wire; wherein the conductor is tinned copper wire, and the insulating layer is made of polyfluoroethylene propylene (FEP) plastic; ( S2) Provide seve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com