Supported platinum based three-way catalyst and preparing method and use

A three-way catalyst and supported technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problems of poor stability, catalyst dehydrogenation activity and low selectivity of low-carbon oxane, and achieve Effects of long service life, high activity, and long olefin selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

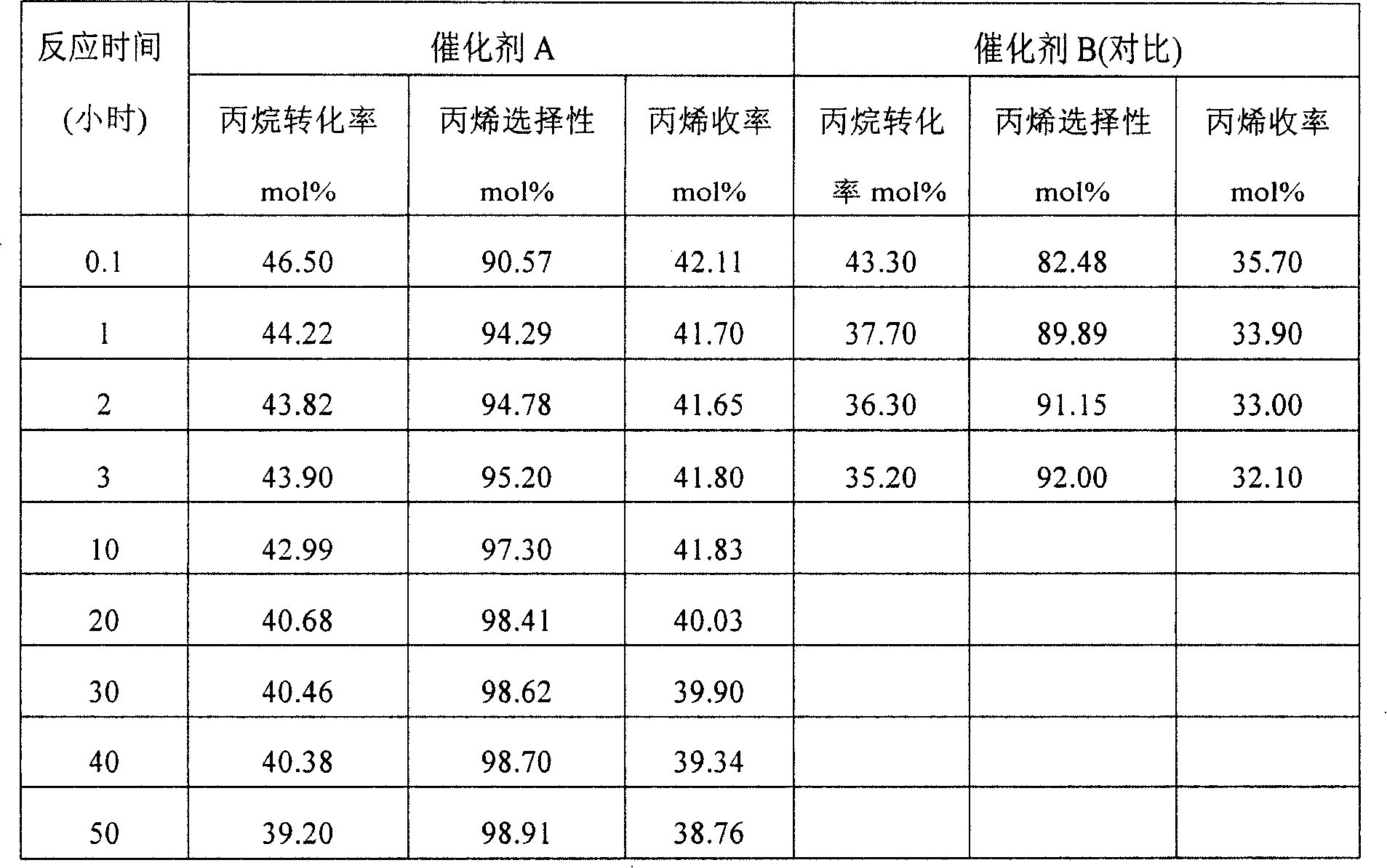

Embodiment 1 and comparative Embodiment 1

[0024] Catalyst A and Comparative Catalyst B were prepared, both containing 0.3% Pt (wt.), 0.9% Sn (wt.). The carrier has a specific surface area ≥ 200m 2 / g, γ-Al with a bulk density of 0.47g / ml 2 o 3 .

[0025] Preparation of Catalyst A: Sieve granular 30-40 mesh γ-Al 2 o 3 as a carrier. Weigh 0.42g Ce(NO 3 ) 3 ·6H 2 O and 0.21 g SnCl 2 2H 2 O was simultaneously dissolved in 24 ml of absolute ethanol to form a solution, and 12 g of γ-Al was weighed 2 o 3 Dipping for 12 hours. Evaporate remaining ethanol to dryness at 70°C in a water bath, and dry at 120°C for 12 hours. The dried sample was placed in a muffle furnace, raised to 500°C at a rate of 5°C / min, calcined in an air atmosphere for 4 hours, and cooled to room temperature. Weigh 1 gram of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) Dissolve in 250 ml deionized water. Take 24.56 ml of chloroplatinic acid solution and immerse the cooled sample for 12 hours, evaporate the remaining water in a water bath at 7...

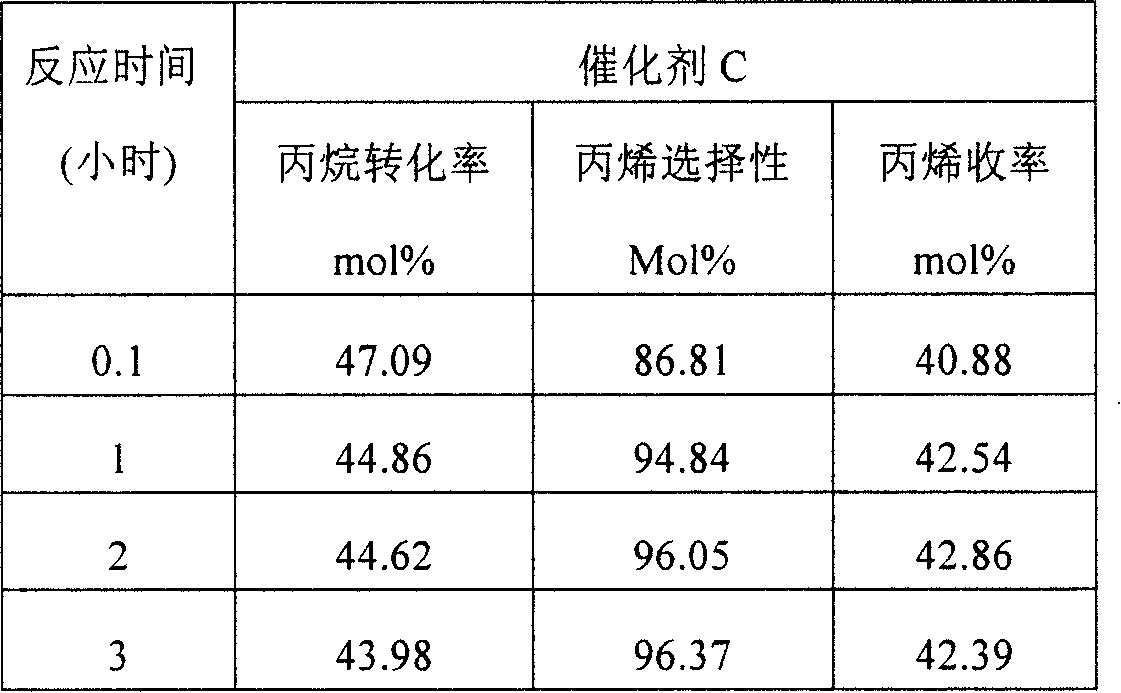

Embodiment 2

[0029]Preparation of Catalyst C. The preparation steps are: sieving granular 30-40 mesh γ-Al 2 o 3 as a carrier. Weigh 0.84 g Ce(NO 3 ) 3 ·6H 2 O and 0.21 g SnCl 2 2H 2 O was simultaneously dissolved in 24 ml of absolute ethanol to form a solution, and 11.87 g of γ-Al 2 o 3 Dipping for 12 hours. Evaporate the remaining ethanol in a water bath at 70°C, and then dry at 120°C for 12 hours. The dried sample was placed in a muffle furnace, raised to 500°C at a rate of 5°C / min, baked in air for 4 hours, and cooled to room temperature. Weigh 1 gram of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) Dissolve in 250 ml deionized water. Take 24.56 ml of chloroplatinic acid solution and immerse the cooled sample for 12 hours, evaporate the remaining water in a water bath at 70°C, and dry at 120°C for 12 hours. The dried sample is placed in a muffle furnace at a rate of 5°C / min Raised to 500, roasted in the air for 4 hours to prepare catalyst C, its expression is: 0.3%Pt-0.9%Sn-2....

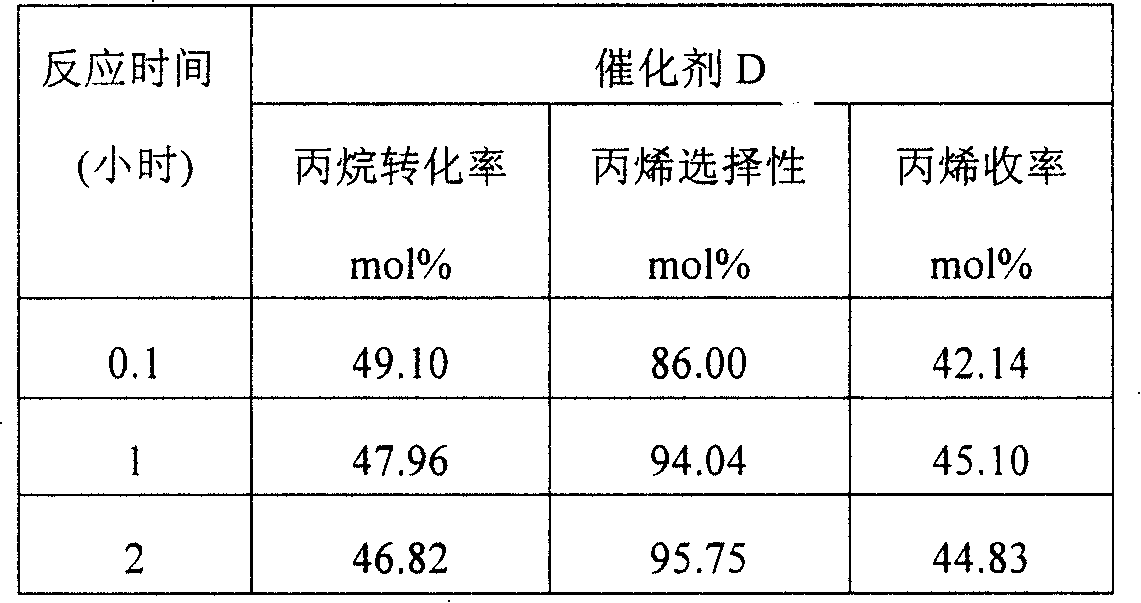

Embodiment 3

[0032] Catalyst D was prepared. The preparation steps are: sieving granular 30-40 mesh γ-Al 2 o 3 as a carrier. Weigh 0.84 g Ce(NO 3 ) 3 ·6H 2 O and 0.21 g SnCl 2 2H 2 O was simultaneously dissolved in 24 ml of absolute ethanol to form a solution, and 11.83 g of γ-Al 2 o 3 Dipping for 12 hours. Evaporate the remaining ethanol in a water bath at 70°C, and then dry at 120°C for 12 hours. The dried sample was placed in a muffle furnace, raised to 500°C at a rate of 5°C / min, baked in air for 4 hours, and cooled to room temperature. Weigh 1 gram of chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) Dissolve in 250 ml deionized water. Take 49.12 ml of chloroplatinic acid solution and immerse the cooled sample for 12 hours, evaporate the remaining water in a water bath at 70°C, and dry at 120°C for 12 hours. The dried sample is placed in a muffle furnace at a rate of 5°C / min Raised to 500, roasted in the air for 4 hours to prepare catalyst C, its expression is: 0.6%Pt-0.9%Sn-2.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com