Domestic garbage landfilling and processing technique with in-situ denitrogenation function and bioreactor

A bioreactor and domestic waste technology, which is applied in the direction of biological sludge treatment, sludge treatment, solid waste removal, etc., can solve the problems of high ammonia nitrogen concentration and achieve high treatment efficiency and low investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

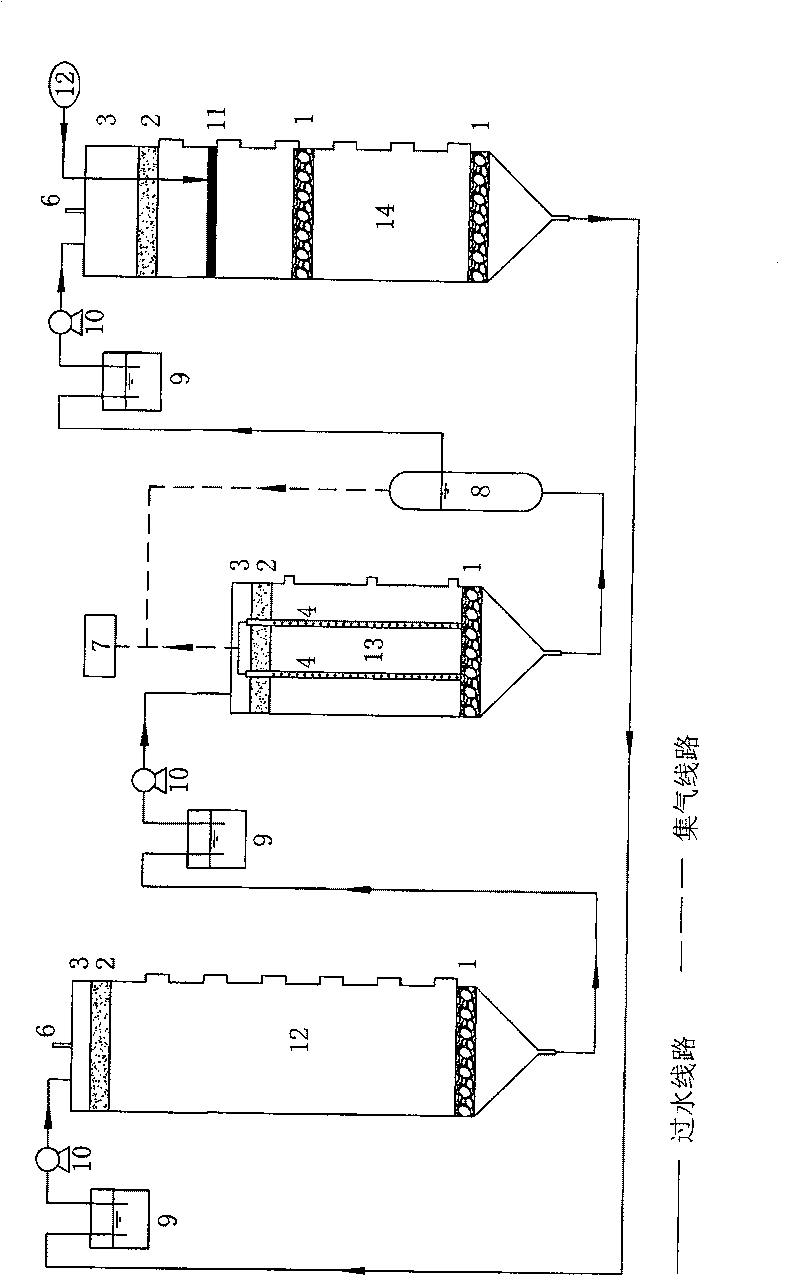

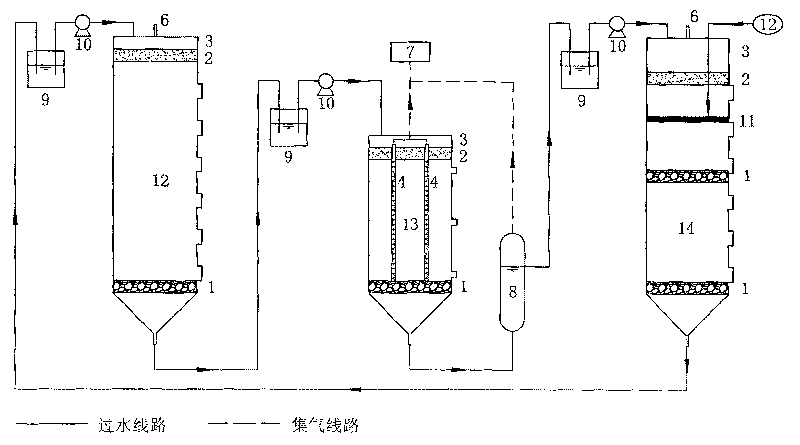

[0015] Such as figure 1 As shown, a domestic waste landfill bioreactor with in-situ denitrification function is composed of a three-stage reactor followed by a fresh landfill 12, a methanogenic reactor 13 and a nitrification reactor 14 through the previous stage of reaction. The leachate outlet at the bottom of the reactor is connected to the top leachate water inlet of the last stage reactor through a water collection bottle 9 and a water inlet pump 10. The reactors at all levels are equipped with garbage chambers and air chambers 3. The chamber 3 is provided with an air duct 6 to facilitate the collection and utilization of landfill gas.

[0016] The bottom of the garbage chamber of the reactors at all levels is covered with a gravel layer 1 to facilitate the smooth discharge of leachate, and the top is provided with a sand layer 2 .

[0017] The leachate water outlet at the bottom of the methanogenic reactor 13 is communicated with the top leachate water inlet of the nitri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com