Method for preparing surface porous metal material

A metal material with a porous surface technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as process instability, micropore size, density and distribution are difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

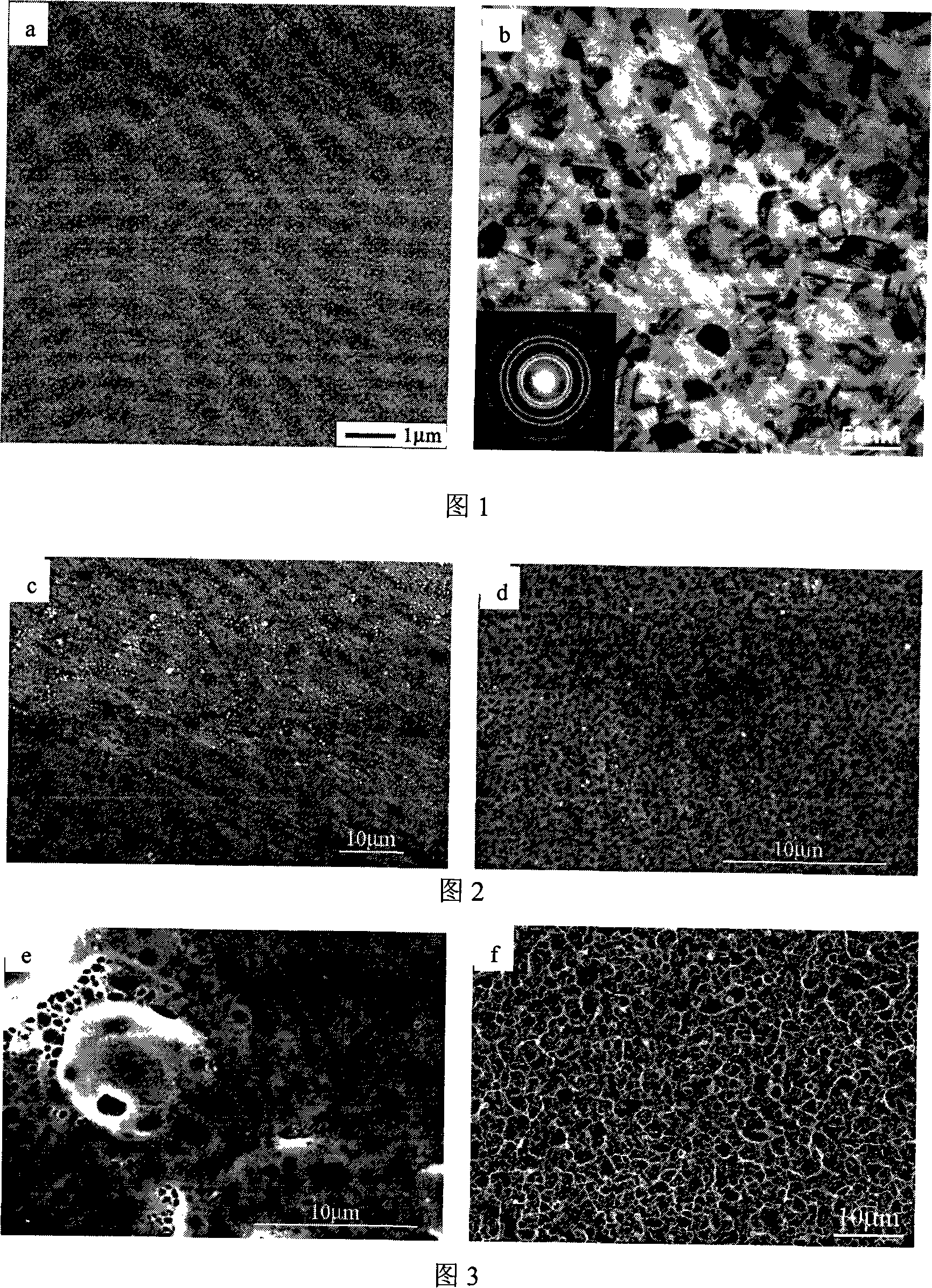

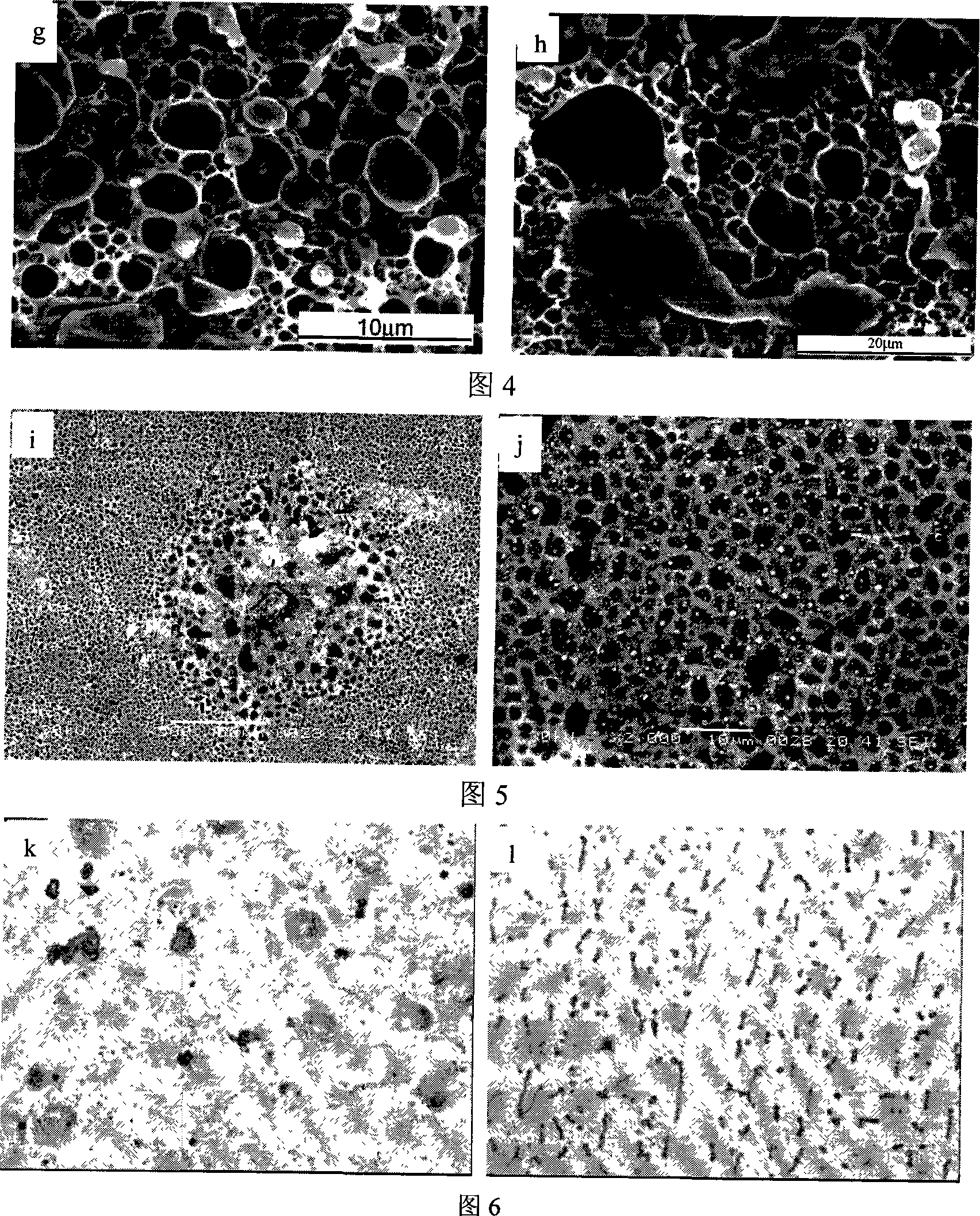

[0019] Polycrystalline pure copper material with nano-grains (average grain size 26nm) was used as the target material (see Figure 1), and Nadezhda-2 low-energy, high-current, short-pulse electron beam device was used for irradiation, and high-current pulse The working parameters of the electron beam irradiation are: the electron beam energy is adjusted between 18-28KeV, the pulse time is 3.5μs, and the vacuum chamber pressure is about 10 -5 Torr, the pulsed electron beam energy density was controlled at 2 J / cm by adjusting the distance between the workpiece and the cathode, respectively 2 , 3 J / cm 2 and 4 J / cm 2 The samples were irradiated. Through experimental research, the conditions for forming surface microporous pure copper are obtained as follows:

[0020] The energy density of the pulsed electron beam is 2 J / cm 2 When irradiated 10 times, pores with a size of about 50nm and fairly uniform distribution can be obtained. The pores are separated from each other, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com