Lines superimposing type packing paper and producing method thereof

A production method and technology of tipping paper, applied in the field of packaging materials, can solve the problems of transfer paper such as inconspicuous laser effect, single visual effect, and difficulty in large-scale production, so as to achieve bright and dazzling color, enhance visual effect, and improve anti-counterfeiting effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

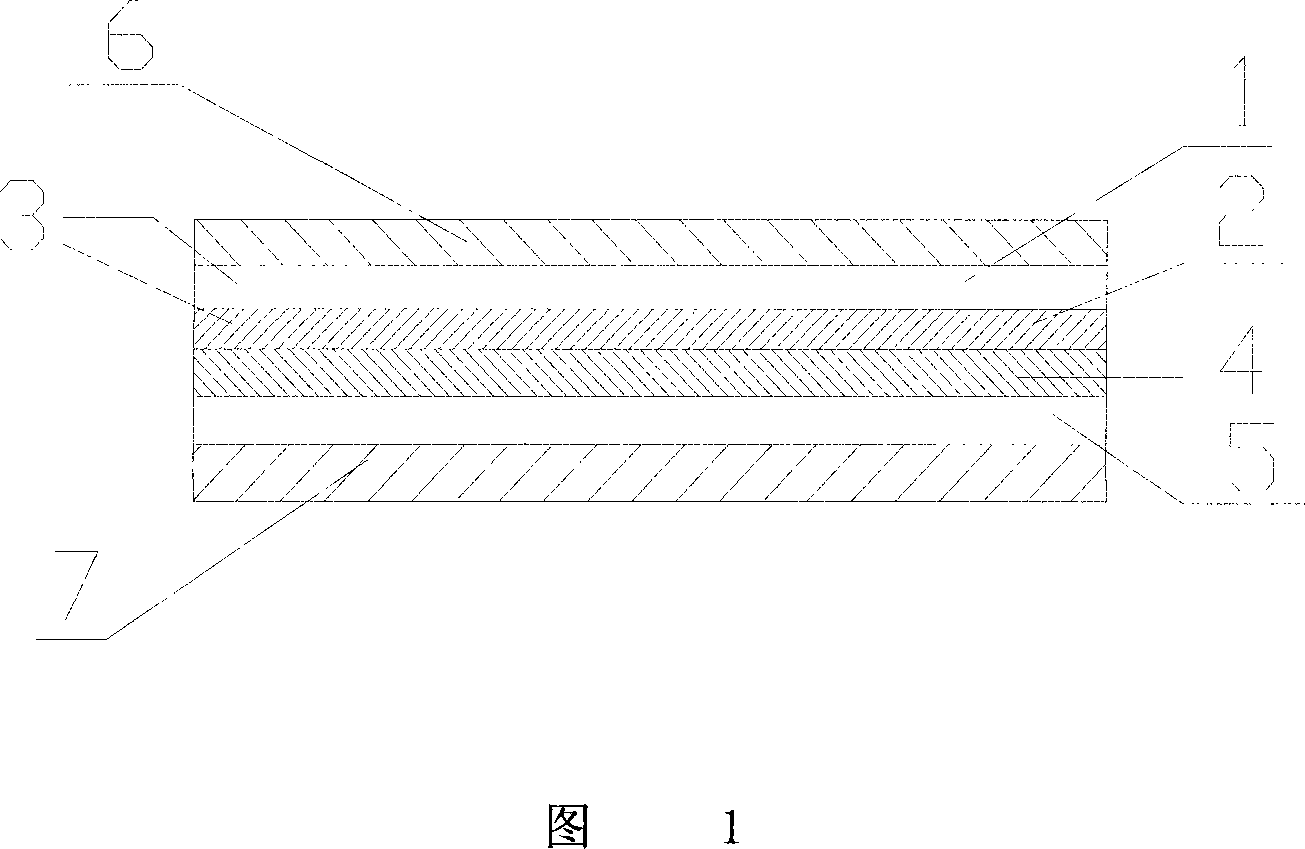

[0020] The present invention comprises sequentially compounded bottom layer 7, adhesive layer 5, aluminum plating layer 4 and surface layer 3, and described surface layer 3 is made of transparent surface coating 1 and printing layer 2, is characterized in that: also comprises at least one layer The color line layer 6, the color line layer 6 is bonded with the surface layer 3.

[0021] The above colored line layer 6 is formed by ink printing. The above-mentioned colored line layer 6 is formed by dye printing. The thickness of the transparent surface coating 1 on the surface layer 3 is 0.5 μm-1.5 μm.

[0022] The method for producing line superposition type tipping paper of the present invention comprises the following steps:

[0023] a. Coating: Use PET plastic light film as the base material, and evenly coat a layer of polymer resin material on the base material. After drying and solidifying, a layer of transparent surface coating 1 with peelable properties is formed;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com