6nm-100nm wave band extreme ultraviolet imaging optical instrument imaging quality test device

A 6nm-100nm, extreme ultraviolet imaging technology, which is applied in the field of imaging quality testing devices for extreme ultraviolet imaging optical instruments, can solve the problems that the detection of imaging quality resolution cannot be realized, and the imaging quality detection of extreme ultraviolet imaging systems cannot be realized. Simple, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

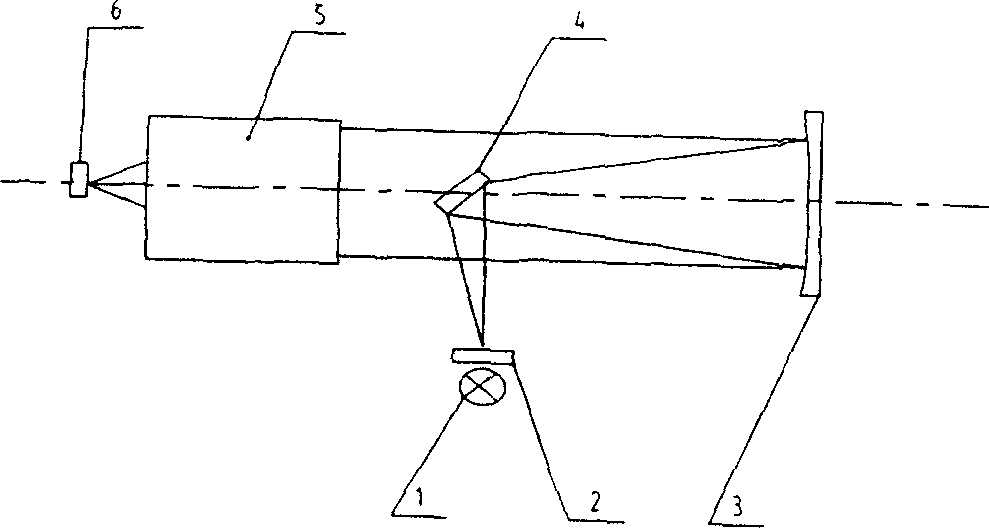

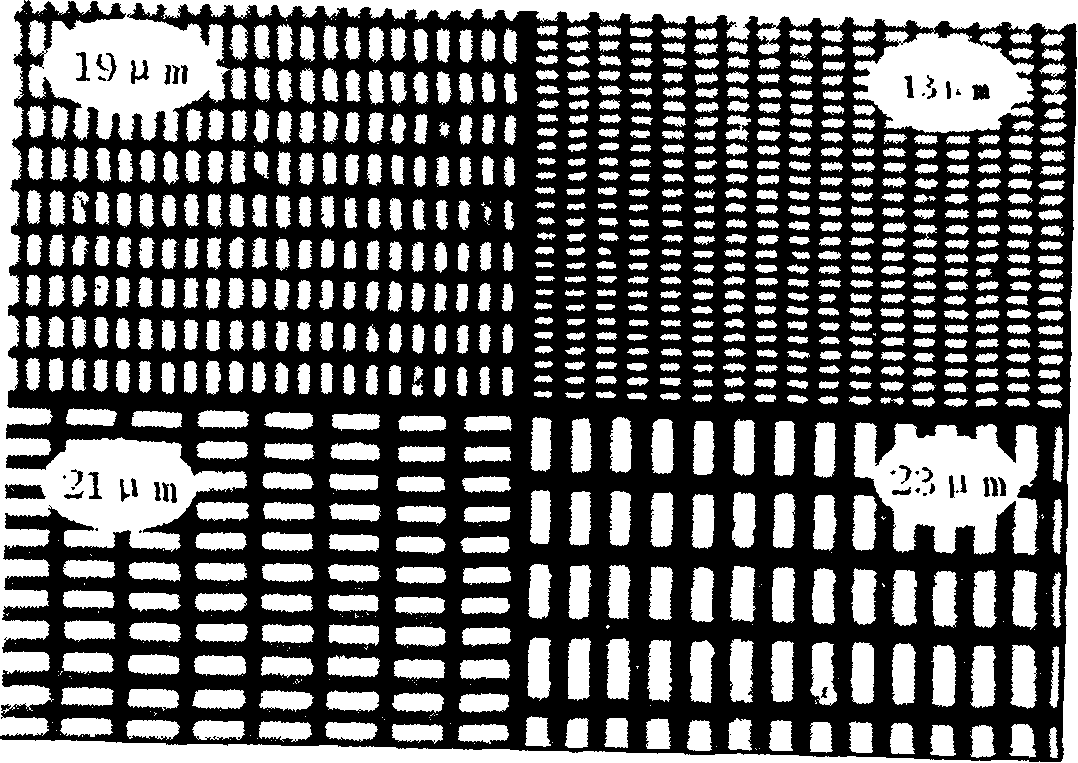

[0012] The entire optical system is under vacuum conditions. The EUV light source 1 emits an EUV light beam that passes through a precision-drawn metal grid 7, hits the mirrors 3 and 4, and finally passes through the EUV imaging optical system 5 to be tested in the EUV camera 6. On the imaging, the grid scale of the metal grid is compared with the formed image, and the resolution data of the optical system to be tested can be obtained after calculation.

[0013] Hollow cathode light source can be selected as the extreme ultraviolet light source, and the grid can be obtained by micro-machining method, and the grid grid precision is 19 μm. Made of nickel metal.

specific Embodiment approach 2

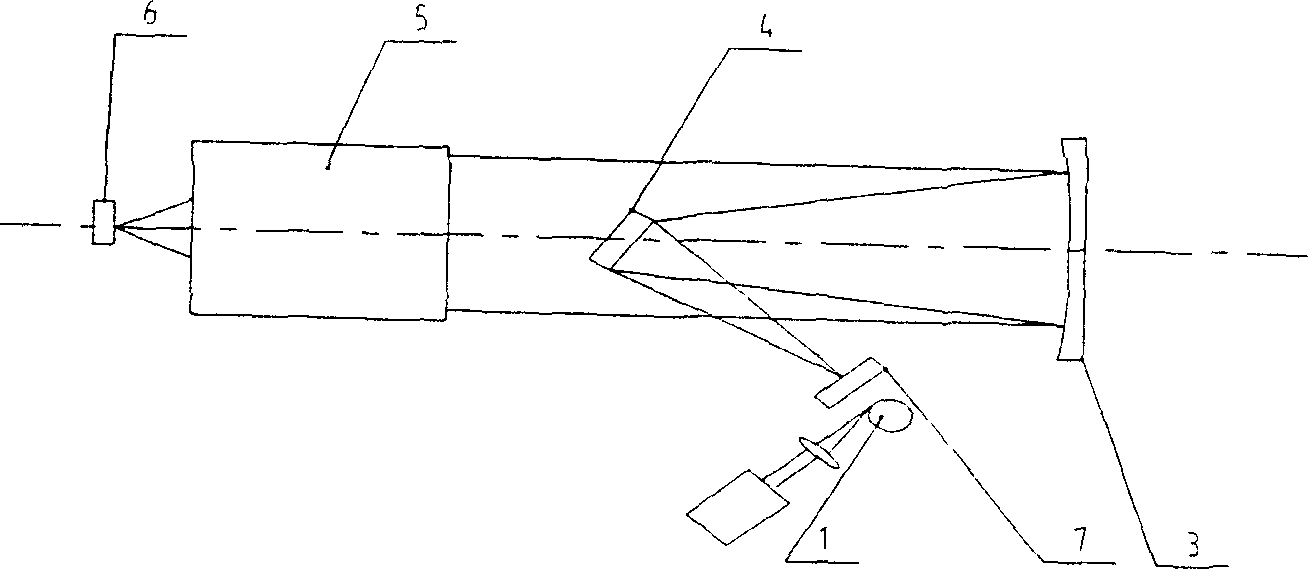

[0014] The entire optical system is under vacuum conditions. The EUV light source 1 emits an EUV light beam that passes through a precision-drawn metal grid 7, hits the mirrors 3 and 4, and finally passes through the EUV imaging optical system 5 to be tested in the EUV camera 6. On the imaging, the grid scale of the metal grid is compared with the formed image, and the resolution data of the optical system to be tested can be obtained after calculation.

[0015] The extreme ultraviolet light source is a laser plasma light source, and the grid can be obtained by the synchrotron radiation LIGA process, and the grid grid accuracy is 13 μm. Made of nickel metal.

specific Embodiment approach 3

[0016] The entire optical system is under vacuum conditions. The EUV light source 1 emits an EUV light beam that passes through a precision-drawn metal grid 7, hits the mirrors 3 and 4, and finally passes through the EUV imaging optical system 5 to be tested in the EUV camera 6. On the imaging, the grid scale of the metal grid is compared with the formed image, and the resolution data of the optical system to be tested can be obtained after calculation.

[0017] The extreme ultraviolet light source is a laser plasma light source, and the grid is obtained by the synchrotron radiation LIGA process, and the grid accuracy is 2 μm. Made of nickel metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com