Separator disk on multi-cell component mix liquid separating system and application method of the same

A technology of liquid separation and separation disc, which is applied in the direction of liquid separation, separation method, and dispersed particle separation, etc., and can solve problems such as time-consuming, labor-intensive, low efficiency, and unfavorable to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

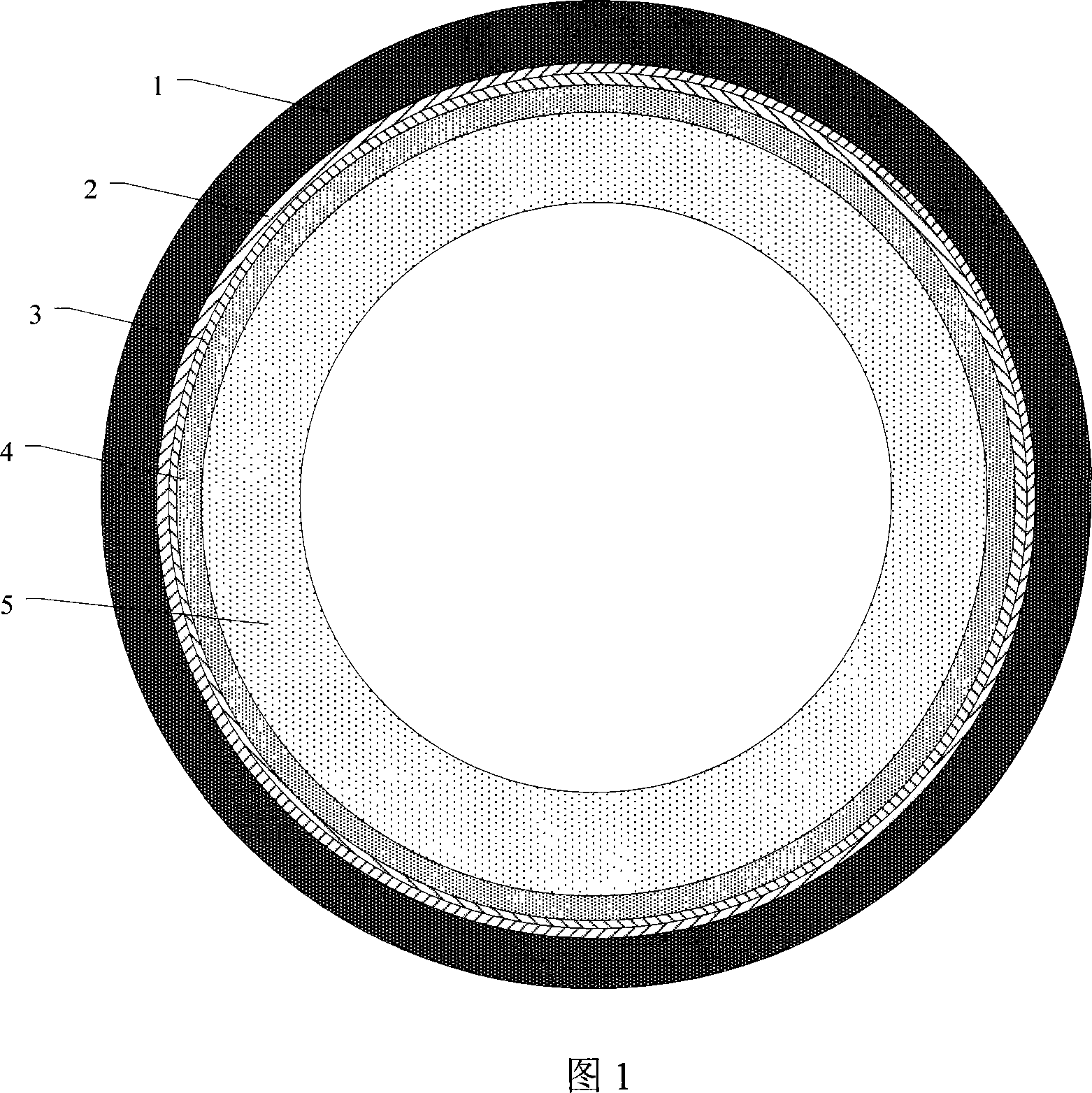

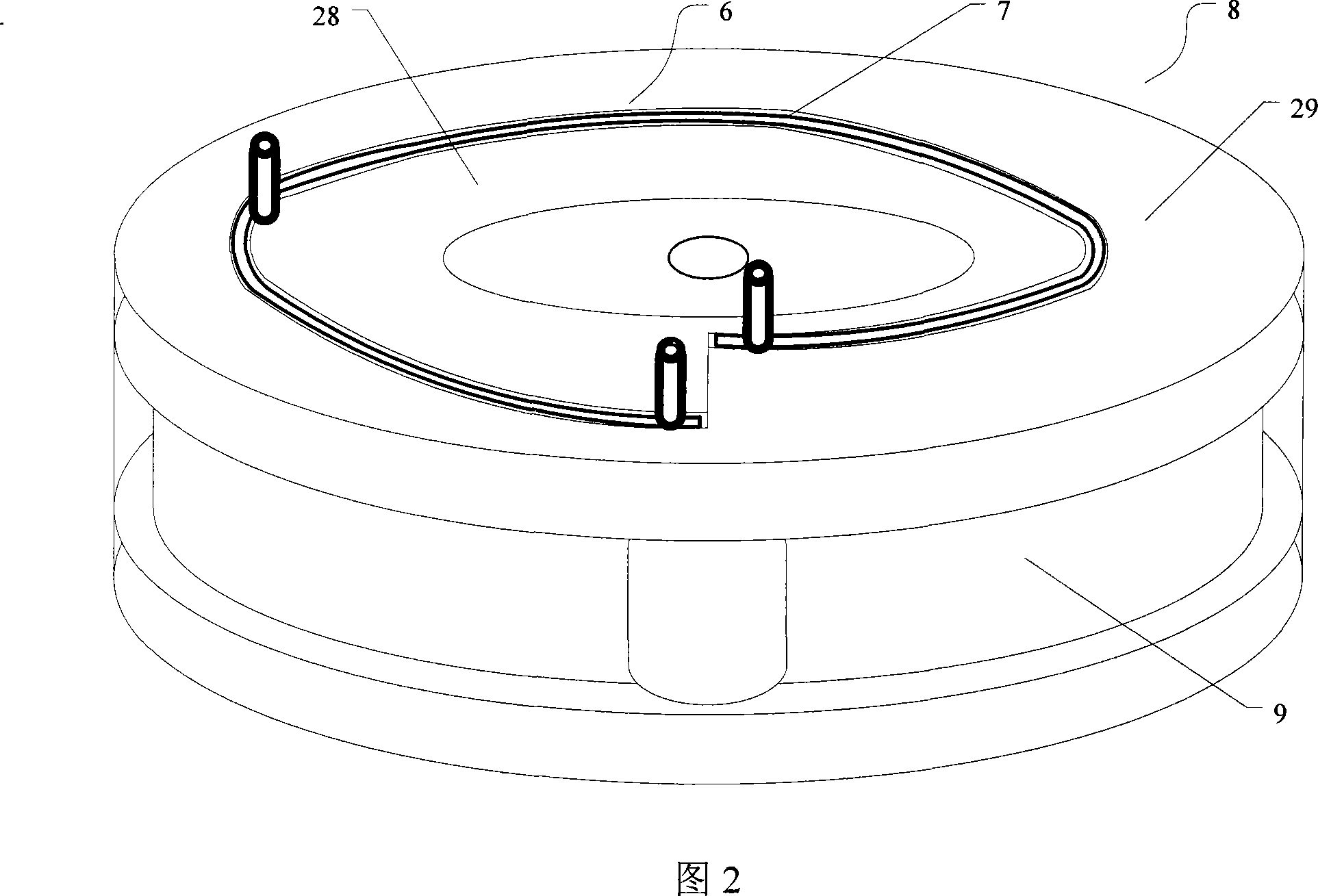

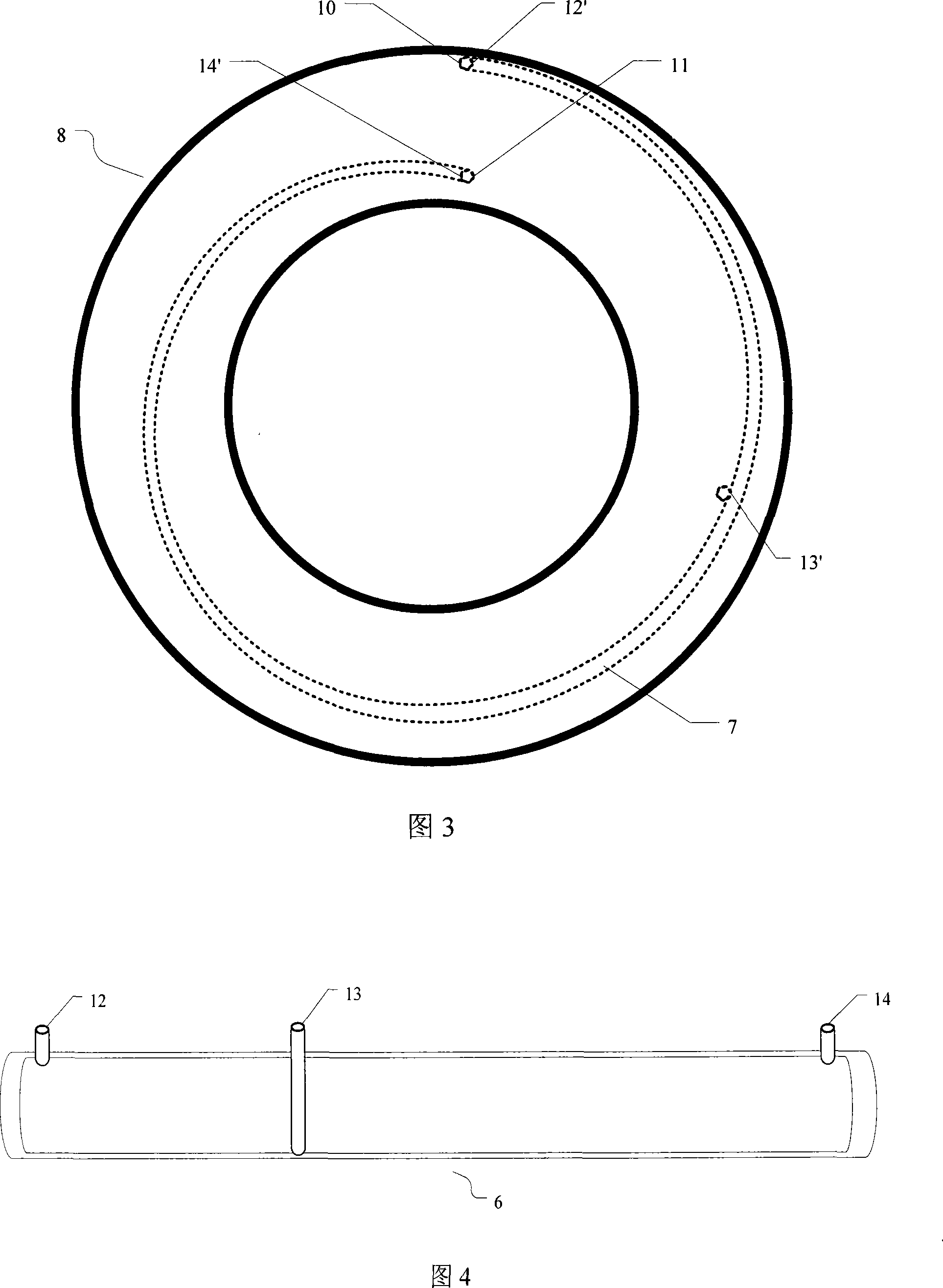

[0060] What this embodiment involves is a separation disk with a single arc-shaped cavity structure, and the single-arc-shaped cavity is specialized as a helical segment cavity around the central axis of the hard chassis. It is mainly used for the continuous separation of the lowest density component in a mixed liquid of multicellular components, such as plasma in whole blood, or the continuous separation of the highest density component in a mixed liquid of multicellular components, such as red blood cells in whole blood.

[0061] Please see Fig. 3 and Fig. 4. Fig. 3 is a schematic view of the single arc-shaped cavity hard chassis of the separation disc in the embodiment 1 of the multi-cell component mixing liquid separation system of the present invention. Fig. 4 is a schematic diagram of the structure of the single-curve soft bag of the embodiment 1 of the separation disc on the multi-cell component mixing liquid separation system of the present invention. It can be seen fr...

Embodiment 2

[0068] In order to realize the extraction of components whose density is in the middle position in the mixed liquid layering, the cavity design is further optimized, and the cavity is composed of a plurality of smooth arc segments that are bent towards the central axis and connected end to end, and the entire cavity is continuous , the curvature of each smooth arc segment is different, the tail of the previous arc segment in two adjacent smooth arc segments is connected with the head of the next arc segment, and the connection of the adjacent arc segments It is a ridge protruding toward the central axis of the circle; in order to adapt to the structure of the cavity, additional liquid outlet tubes with the same number as the number of ridges in the cavity are added on the soft bag. When the soft bag is placed in the cavity, the additional liquid outlet tubes The furthest distance from the central axis of the arc segment behind the crest.

[0069] What is involved in this embod...

Embodiment 3

[0080] In order to realize the extraction of components whose density is in the middle position in the mixed liquid layering, the cavity design is further optimized, and the cavity is composed of a plurality of smooth arc segments that are bent towards the central axis and connected end to end, and the entire cavity is continuous , the curvature of each smooth arc segment is different, the tail of the previous arc segment in two adjacent smooth arc segments is connected with the head of the next arc segment, and the connection of the adjacent arc segments It is a ridge protruding toward the central axis of the circle; in order to adapt to the structure of the cavity, additional liquid outlet tubes with the same number as the number of ridges in the cavity are added on the soft bag. When the soft bag is placed in the cavity, the additional liquid outlet tubes The furthest distance from the central axis of the arc segment behind the crest.

[0081] What this embodiment involves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com