Heat exchanger

A heat exchanger and core tube technology, which is applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problem of poor contact between the core tube and the coil tube, the strength of the raised part is reduced, and the heat transfer performance is reduced. and other problems to achieve the effect of eliminating poor contact, avoiding strength reduction, and improving heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The heat exchanger of the present invention is explained with reference to the drawings and examples.

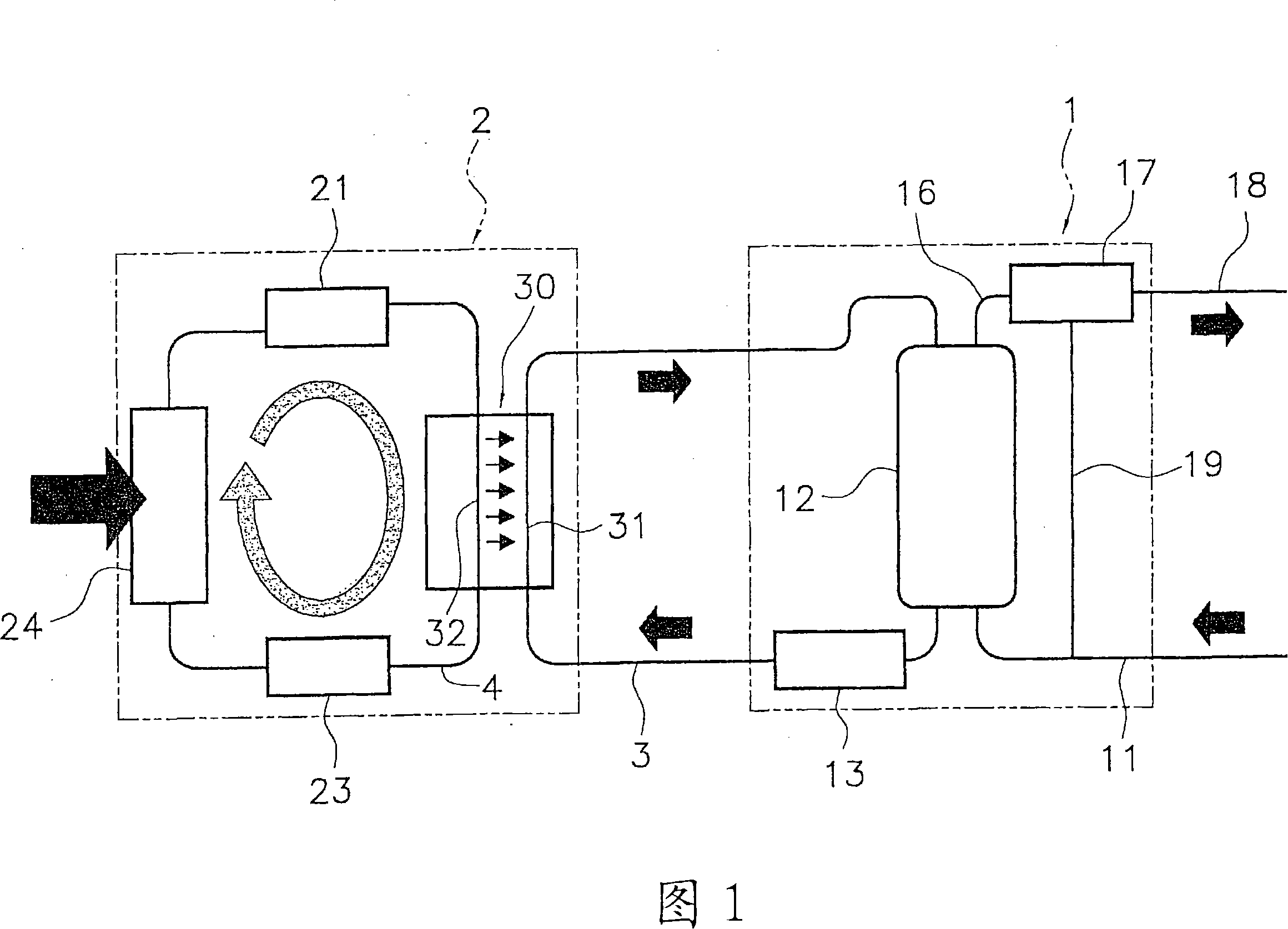

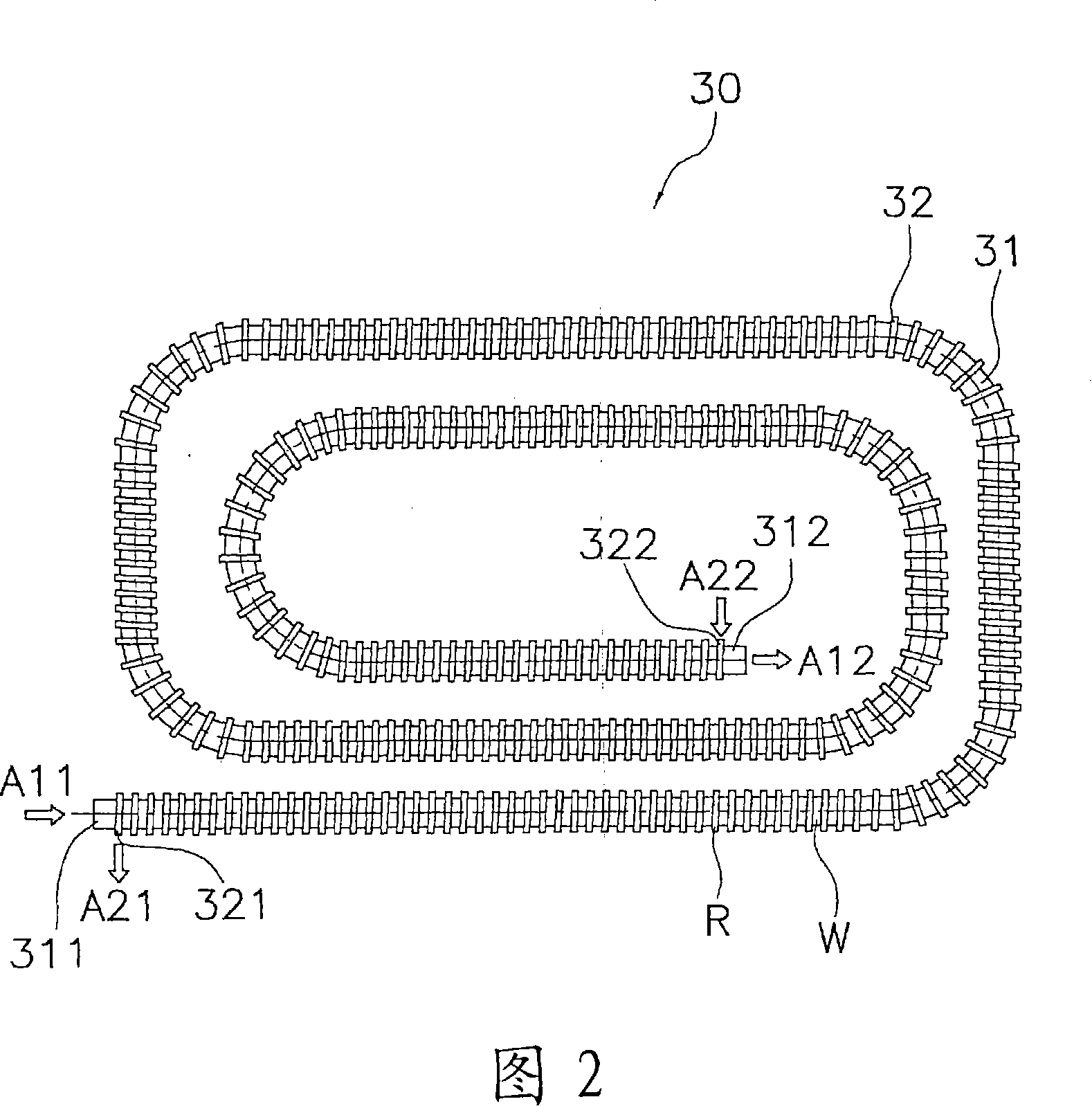

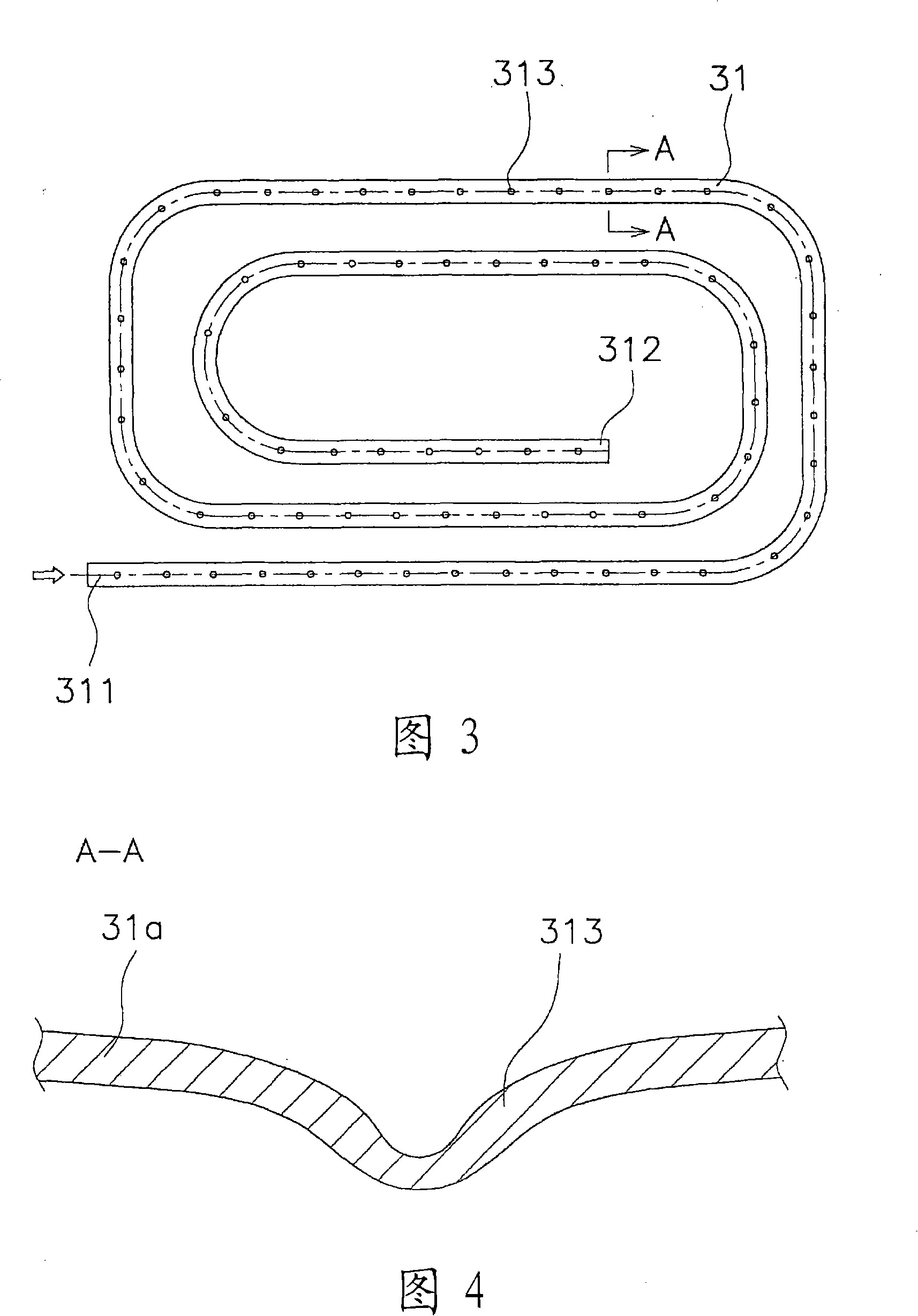

[0036] Fig. 1 is a schematic diagram of a heat pump water heater using the heat exchanger of the present invention. In the heat pump type water heater shown in FIG. 1, it takes a long time to heat water from about 10 degrees to about 90 degrees in one direction in order to efficiently use nighttime electricity which is cheap in electricity costs. Here, the heat pump water heater has a water supply unit 1 and a heat pump unit 2 . The hot water supply unit 1 is connected in sequence with a tap water pipe 11, a hot water storage tank 12, a water circulation pump 13, a water supply pipe 3, a core pipe 31 constituting a water heat exchanger 30, a warm water pipe 16, a mixing valve 17 and a heat supply unit. water pipe18. Here, tap water is supplied from the tap water pipe 11 to the hot water storage tank 12 . Water at a low temperature is supplied from the bottom of the...

Embodiment 2

[0043] As shown in FIG. 6 , in Example 2, for a heat exchanger in which a plurality of coil tubes 42 , 42 are spirally wound on a core tube 41 , paste solder 43 accommodated in a container 45 is coated. After applying to the coiled pipes 42, 42, brazing is performed using a heating furnace not shown. At this time, the solder 43 melted by heating is poured into the concave portion 414 by capillary suction. Therefore, in the heat exchanger in which a plurality of coil tubes 42 , 42 are helically wound around the core tube 41 , the working efficiency of brazing can be improved. Furthermore, the solder melted by heating is reliably poured into the concave portion, and the cooling adhesion occurs. Therefore, the recess formed on the outer surface of the core pipe is reliably filled with the brazing filler metal, so that poor contact between the core pipe and the coil pipe can be eliminated. And, in the processing of the protrusions, even if the wall thickness of the protrusions o...

Embodiment 3

[0045] As shown in FIG. 7 , in Embodiment 3, the heat transfer tubes 42 forming the refrigerant passage R are not coiled tubes but straight tubes. That is, in the heat exchanger 50, the straight pipe 42 forming the refrigerant passage R is arranged on the outer surface of the core pipe 51 forming the water passage W. Here, the paste-like brazing material 53 is applied in advance to the concave portion 514 formed on the outer surface of the core tube 51 , and then the straight tube 52 is placed on the core tube 51 and brazed using a heating furnace not shown. Then, the solder 53 melted by heating is reliably poured into the concave portion 514, and the cooling sticking occurs. Therefore, the concave portion 514 formed on the outer surface of the core tube 51 is reliably filled with the solder 53 , so that poor contact between the core tube 51 and the straight tube 52 can be eliminated. And, in the process of protruding, even if the wall thickness of the protruding portion 513 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com