Water-soluble carbon nano tube and preparation method thereof

A carbon nanotube, water-soluble technology, applied in the field of materials, can solve the problems of harsh reaction conditions and complicated operation steps, and achieve the effect of great significance and avoiding complicated steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

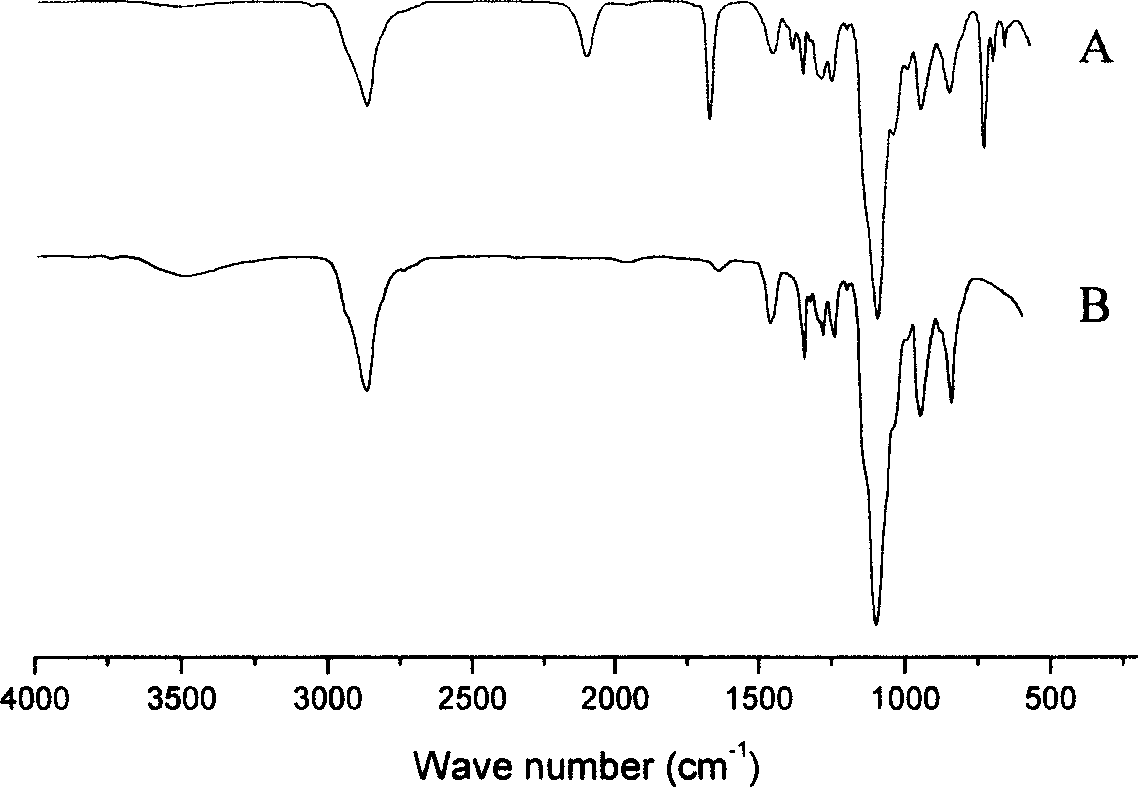

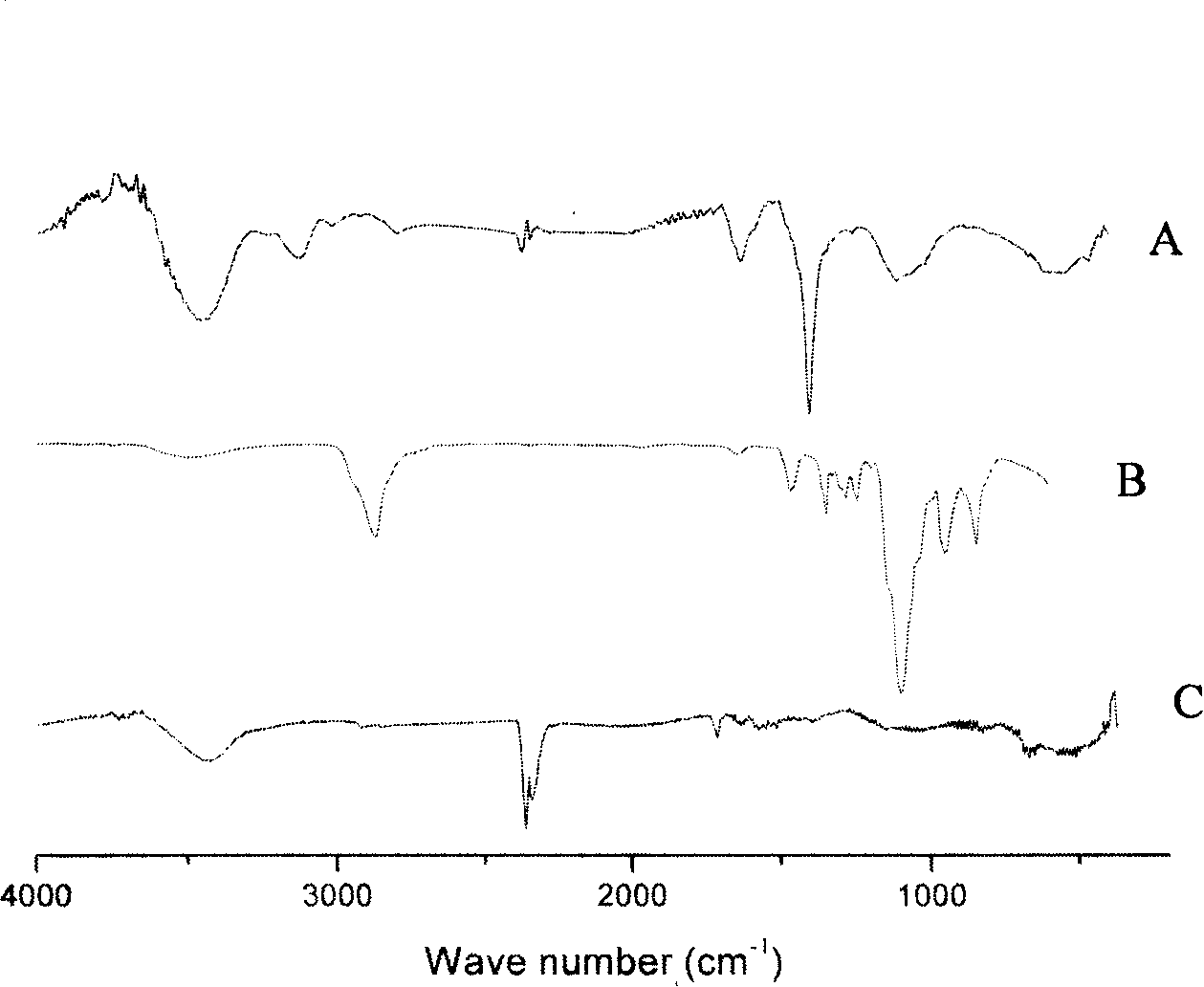

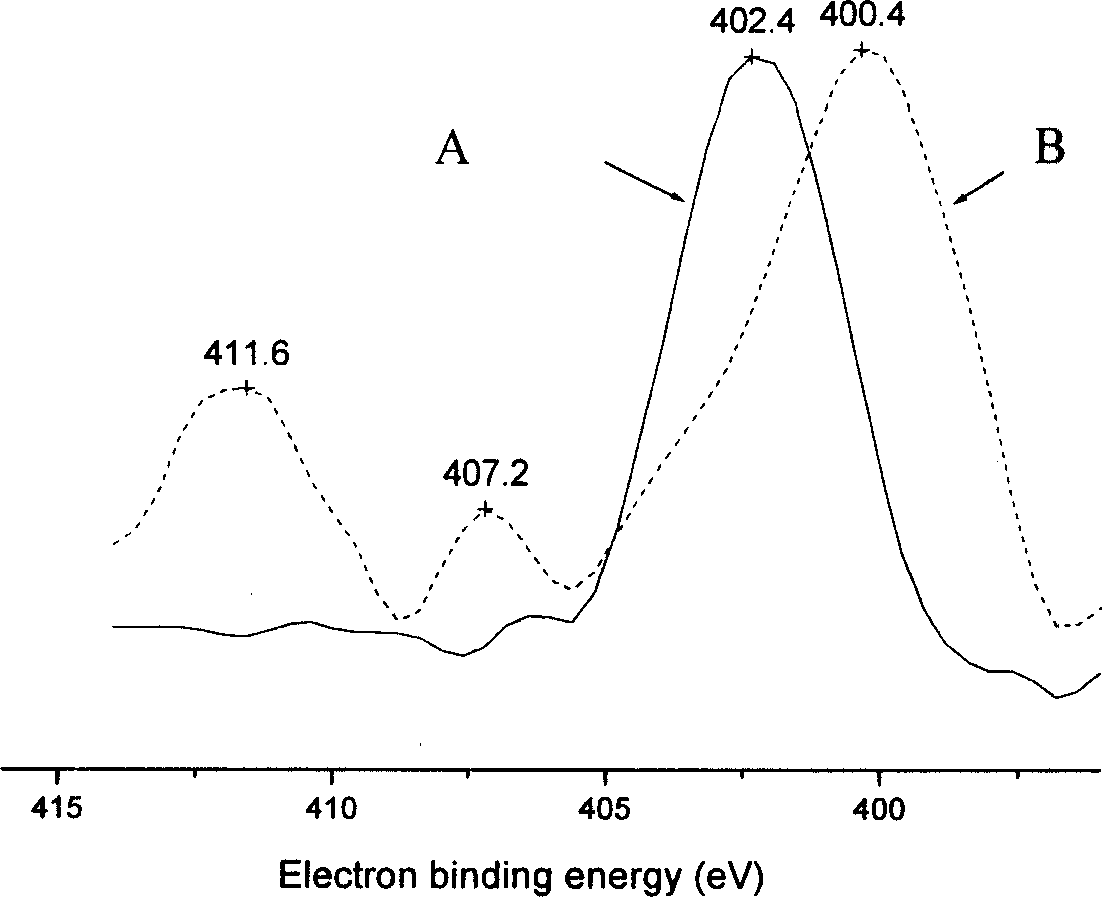

[0028] Example 1: Preparation of water-soluble single-walled carbon nanotube-g-polyethylene glycol monomethyl ether 750

[0029] (a) Add 40ml of 98% nitric acid, 40ml of 96% sulfuric acid and 120ml of dichloromethane into the three-necked flask successively, stir and cool to 0-5°C. 30 ml of dichloromethane dissolved in 20 g of hydroxyl-terminated polyethylene glycol monomethyl ether 750 was slowly added dropwise. The temperature is maintained at 5-8°C. After the dropwise addition, the reaction was continued for 1 h. After the reaction, the reaction mixture was poured into ice water, the dichloromethane layer was separated, and washed continuously with water and 50 wt% aqueous sodium bicarbonate until neutral. After removing the solvent, polyethylene glycol monomethyl ether 750 terminated with nitrate group was obtained.

[0030] (b) Put 10mmol of polyethylene glycol monomethyl ether 750 terminated by nitrate group, 21mmol of sodium azide, and 15mL of distilled water into a t...

Embodiment 2

[0033] Example 2: Preparation of water-soluble multi-walled carbon nanotube-g-polyethylene glycol monomethyl ether 750

[0034] (a) Add 40ml of 98% nitric acid, 40ml of 96% sulfuric acid and 120ml of dichloromethane into the three-necked flask successively, stir and cool to 0-5°C. 30 ml of dichloromethane dissolved in 20 g of hydroxyl-terminated polyethylene glycol monomethyl ether 750 was slowly added dropwise. The temperature is maintained at 5-8°C. After the dropwise addition was completed, the reaction was continued for 1 h. After the reaction, the reaction mixture was poured into ice water, the dichloromethane layer was separated, and washed continuously with water and 50 wt% aqueous sodium bicarbonate until neutral. After removing the solvent, polyethylene glycol monomethyl ether 750 terminated with nitrate group was obtained.

[0035](b) Put 10mmol of polyethylene glycol monomethyl ether 750 terminated by nitrate group, 21mmol of sodium azide, and 15mL of distilled w...

Embodiment 3

[0038] Embodiment 3: Preparation of water-soluble single-walled carbon nanotube-g-polyethylene glycol monooctyl ether 600

[0039] (a) Add 40ml of 98% nitric acid, 40ml of 96% sulfuric acid and 120ml of dichloromethane into the three-necked flask successively, stir and cool to 0-5°C. 30 ml of dichloromethane dissolved in 20 g of hydroxyl-terminated polyethylene glycol monocaprylyl ether 600 was slowly added dropwise. The temperature is maintained at 5-8°C. After the dropwise addition was completed, the reaction was continued for 1 h. After the reaction, the reaction mixture was poured into ice water, the dichloromethane layer was separated, and washed continuously with water and 50 wt% aqueous sodium bicarbonate until neutral. After removing the solvent, polyethylene glycol monooctyl ether 600 terminated by nitrate group was obtained.

[0040] (b) Put 10 mmol of nitrate group-terminated polyethylene glycol monooctyl ether 600, 21 mmol of sodium azide, and 15 mL of distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com