Method for refining glutaraldehyde

A refining method, glutaraldehyde technology, applied in the preparation of heterocyclic compounds, organic chemistry, etc., can solve the problems of darkening of polymerization color, inability to guarantee product color, and failure to meet the requirements of medical grade purification, and achieve the operation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

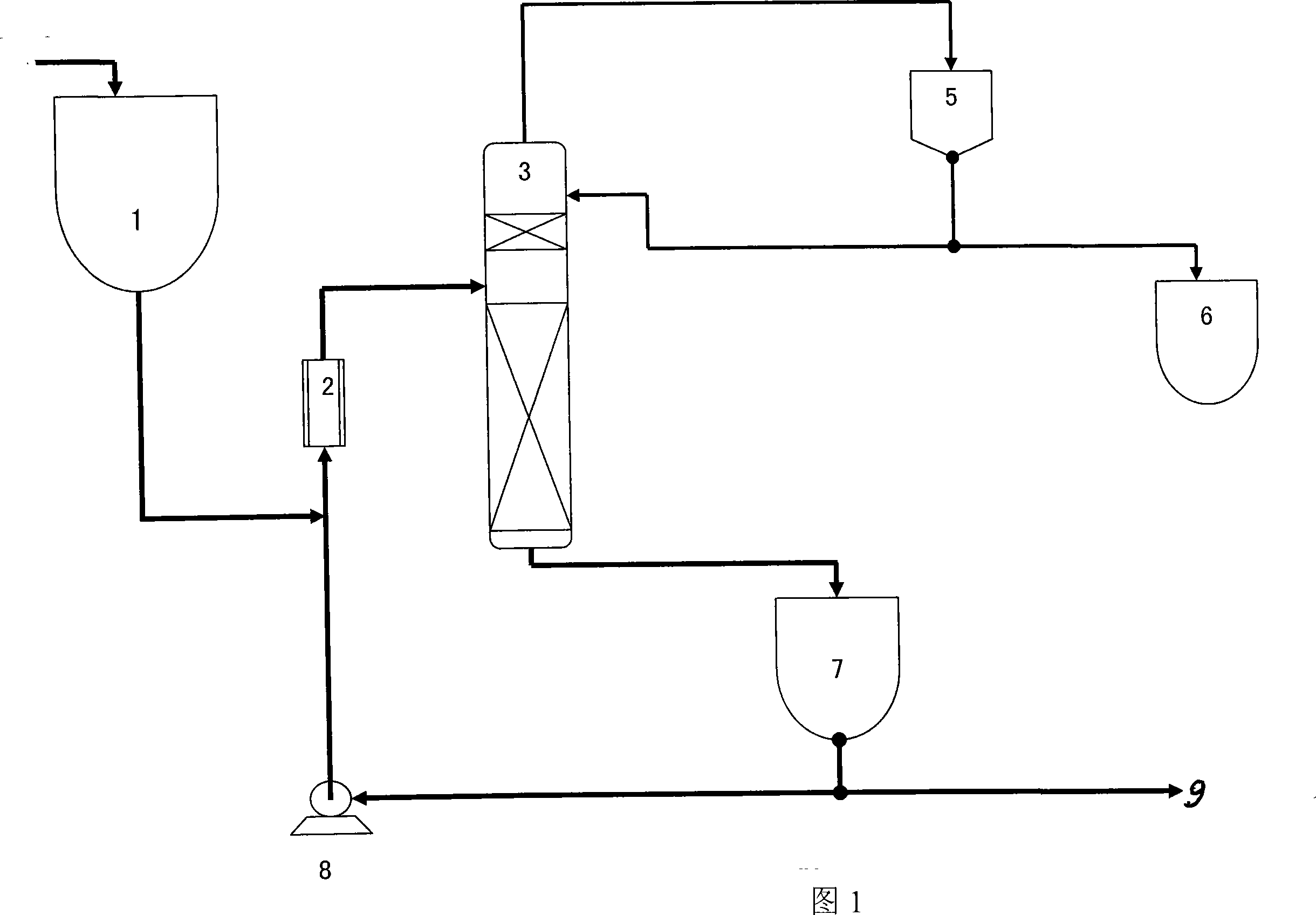

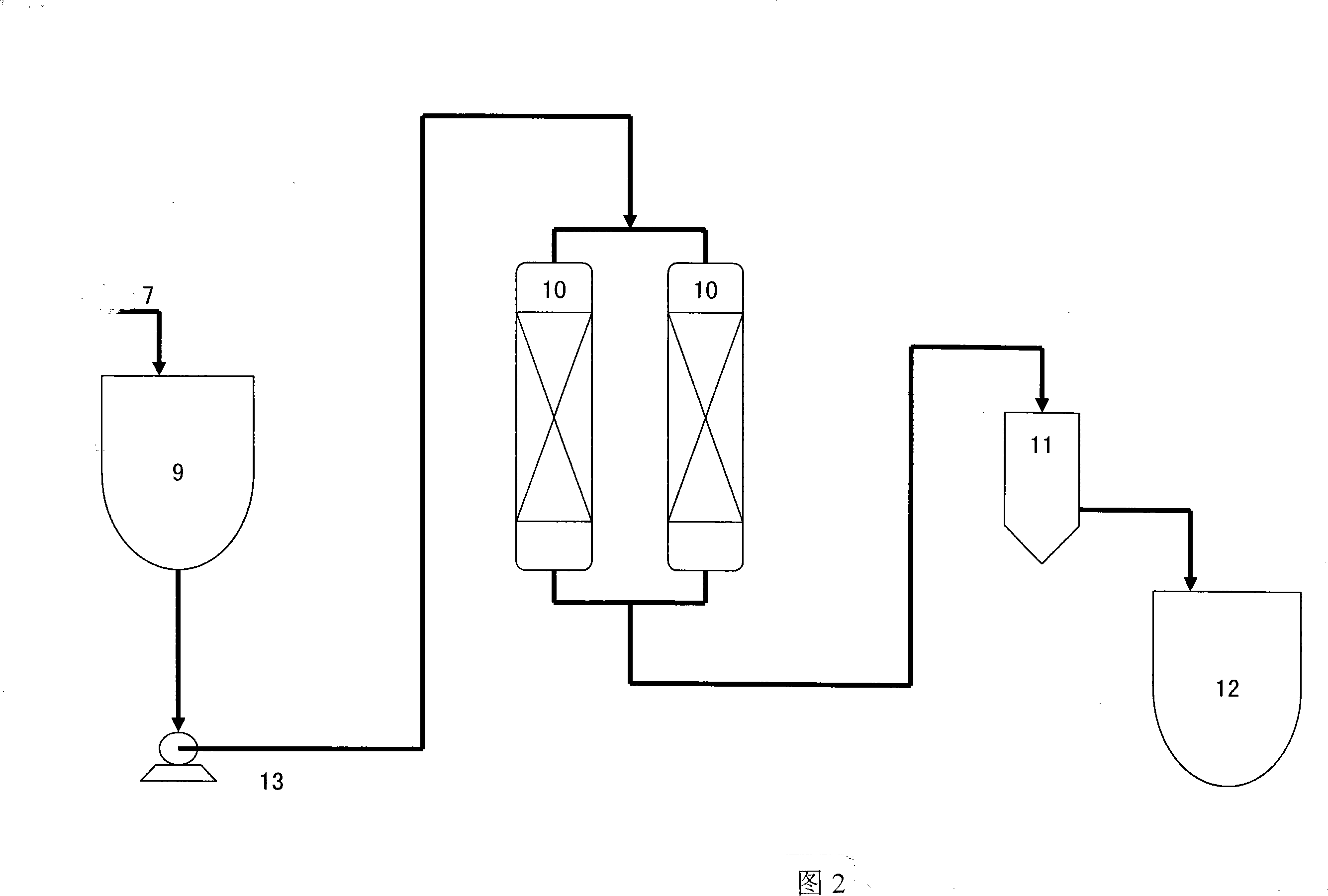

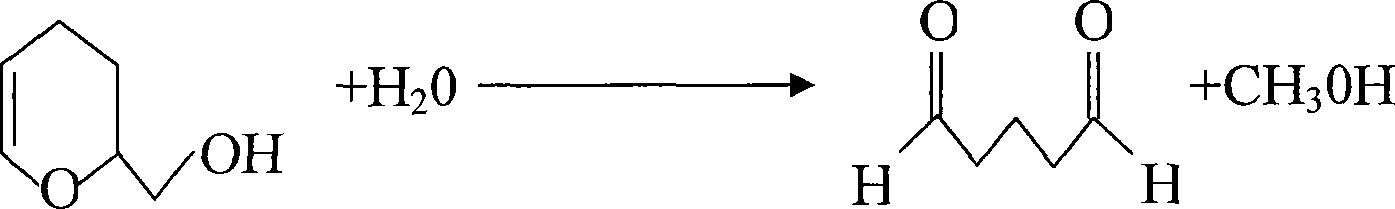

[0027] In a 10,000L reactor, add metered water, 3,4-dihydropyran-2-methyl ether and phosphoric acid catalyst successively, and carry out hydrolysis reaction at 50-90°C for 0.5-2 hours to obtain a concentration of 15-35%. Semi-finished product of glutaraldehyde aqueous solution. The semi-finished product is separated from methanol according to the process flow shown in Figure 1. The temperature of the material when it enters the rectification tower is controlled at 50-95°C, and the vacuum degree of the rectification system is controlled at 0.60-0.96Mpa; after separating methanol, 53.6% The concentrated glutaraldehyde aqueous solution has a chromaticity of No. 60 and a methanol content of 0.35%. After the upper material is decolorized and filtered according to the process flow shown in Figure 2, the glutaraldehyde aqueous solution with a chroma of No. 30 is obtained, and then 15 to 30% NaH 2 PO 4 The pH of the liquid is adjusted to 3.0-5.0, and distilled water is added for pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com