Production technique of fibre for high-strength low-extention polypropylene rope

A production process, polypropylene technology, applied in fiber treatment, fiber chemical characteristics, rayon filament physical therapy and other directions, can solve the problems of high elongation, no UV resistance, low strength, etc., to achieve the effect of optimizing the modification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

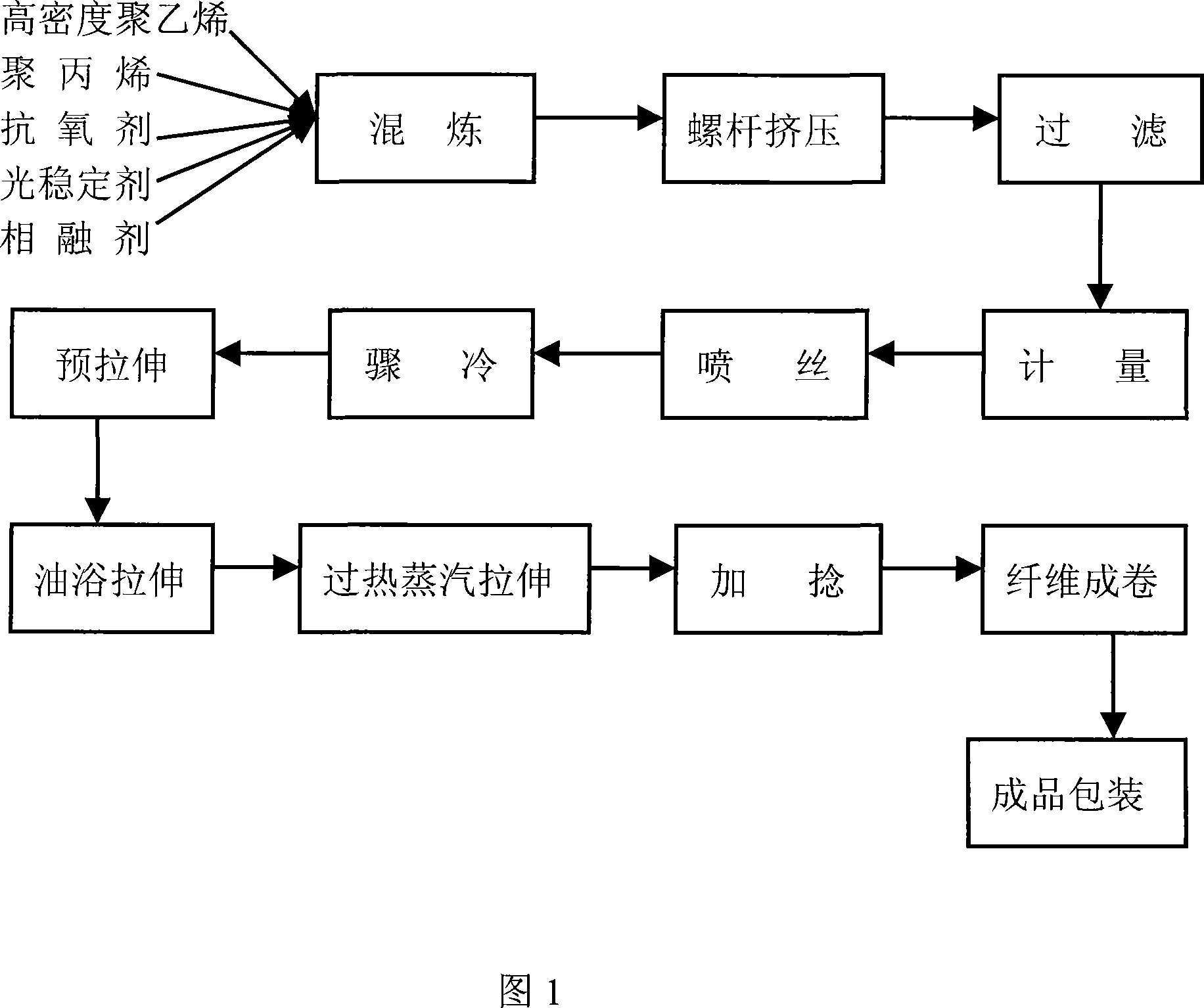

[0022] Refer to the attached drawings, the production process of high-strength and low-elongation polypropylene fiber includes: modification of polypropylene raw materials (participated by copolymers such as polypropylene, high-density polyethylene, light stabilizers, compatibility agents, and antioxidants); twin screw Adjust the aspect ratio to increase by 15%-30% and the screw to increase the mixing device; melt spinning for quenching process: quenching temperature 0-15℃, quenching time 15-30 seconds; high temperature oil bath stretching: Stretching ratio is 6-10 times, oil bath temperature is 80-100℃, oil bath time is 5-10 seconds; high temperature steam stretching: stretching ratio is 0.5-3 times, superheated steam 120~140℃, overheating time 3 ~8 seconds; Multifilament twisting: There are two types of twisting, S-type and Z-type, with 20-80 twists per meter. The total fineness of the finished fiber reaches 5,000 denier to 30,000 denier.

[0023] Specific steps:

[0024] The fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com