Ultrasonic wave automatic detection system of copper and non-corrodible steel variety metal vacuum brazing water joint

A dissimilar metal, automatic detection technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc. Rules, sound wave attenuation and other problems, to achieve the effect of simple structure, diverse functions, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

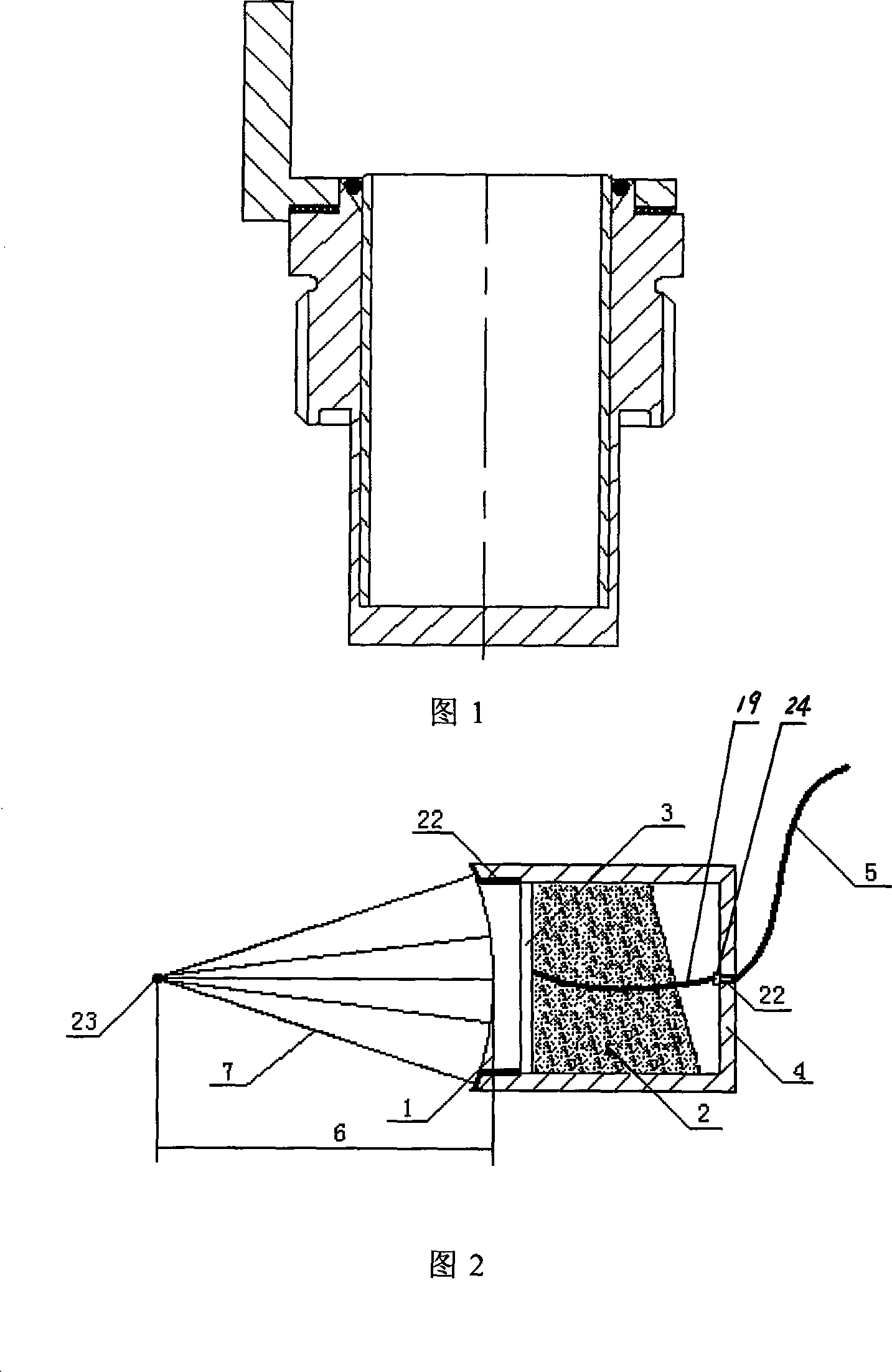

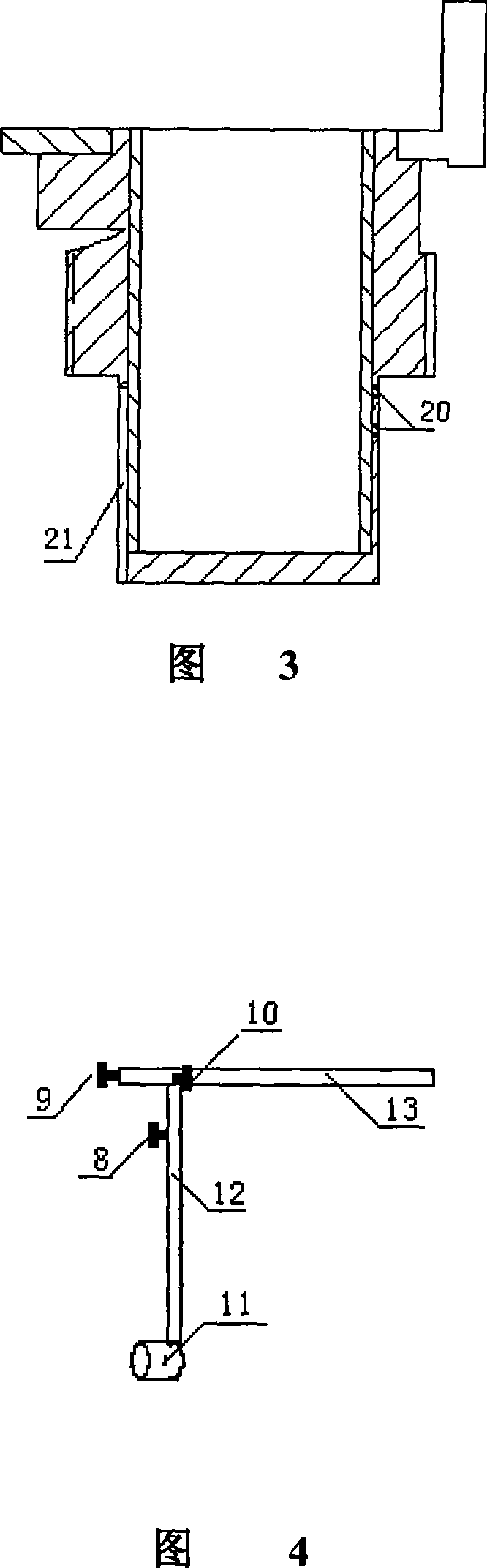

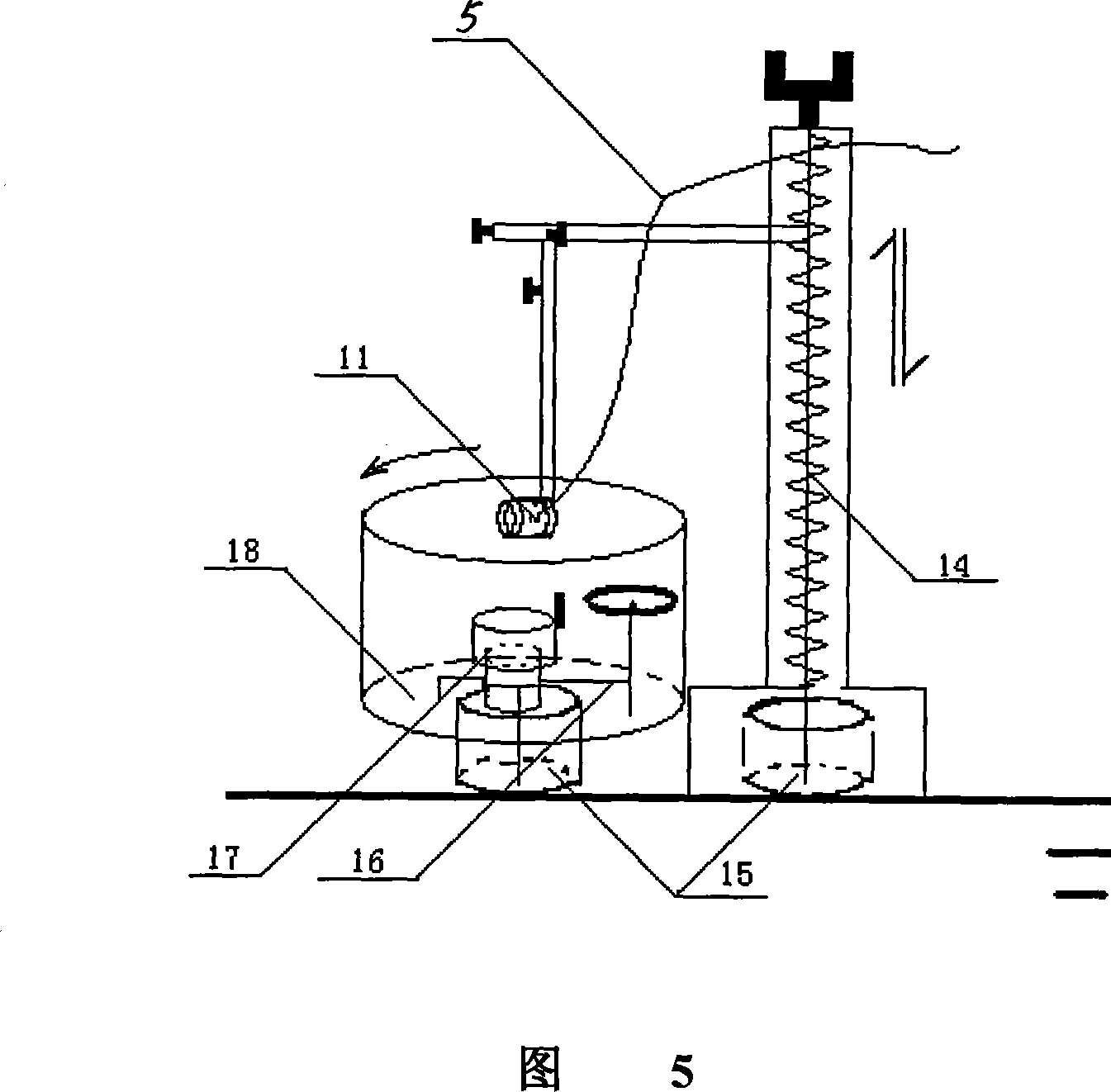

[0045] The ultrasonic testing system for copper and stainless steel dissimilar metal vacuum brazed water joints is composed of hardware and software, in which the hardware is composed of an automatic detection device for water joints, a single crystal water immersion focusing probe, and a comparison test block; the software is composed of a computer program for performing detection tasks composition.

[0046] In the hardware: an automatic detection device for water joints, including an industrial computer, two motor drivers 15 controlled by the industrial computer, two motors controlled by their respective motor drivers, and one of the motors 15 drives a screw rod that can move vertically up and down (i.e. the drive shaft) 14, the screw rod 14 is equipped with a probe recliner composed of a horizontal rod 13 and a vertical rod 12, and the single crystal water immersion focusing probe is installed on the probe fixture at the lower end of the vertical rod 12 of the probe recliner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com