Dye sensitization solar cell and working electrode thereof

A solar cell and working electrode technology, which is applied in the field of dye-sensitized solar cells, can solve the problems of tight space for microelectronic devices, difficult manufacturing cost of photovoltaic cells, constraints on designers' thinking, etc., and achieves small size, easy deformation, and easy series and parallel connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A specific implementation example of the present invention is introduced below;

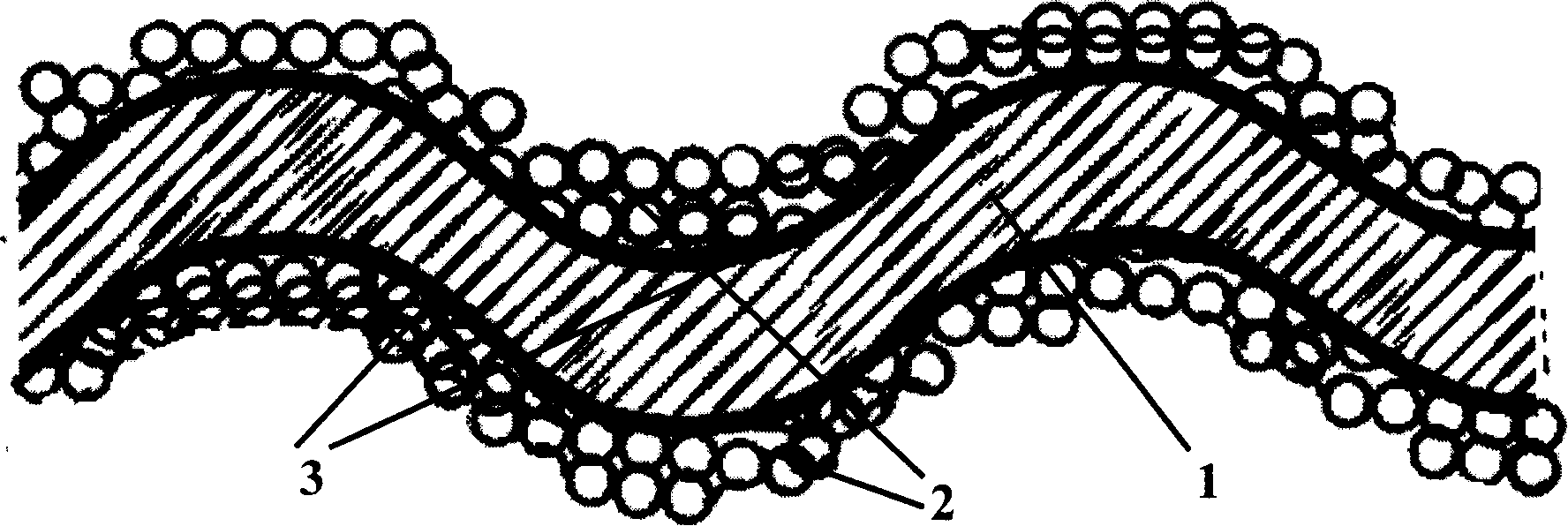

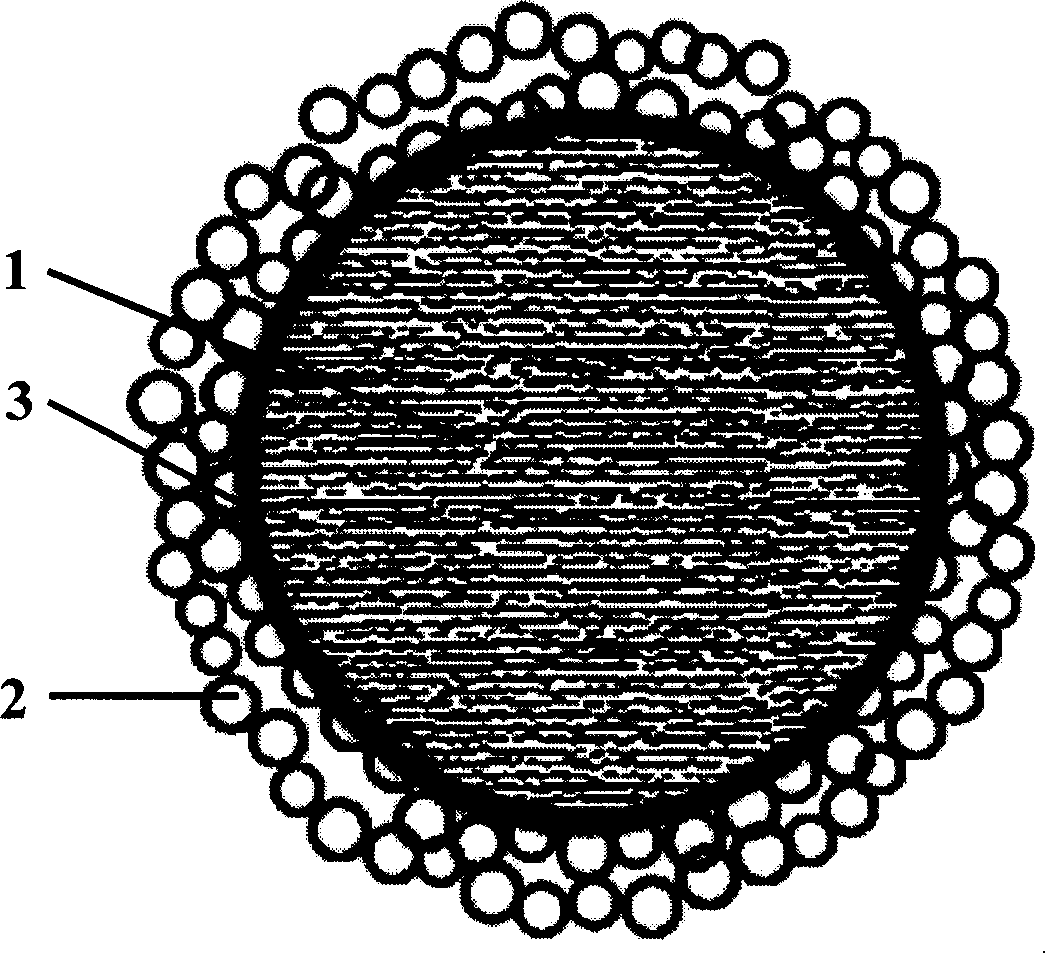

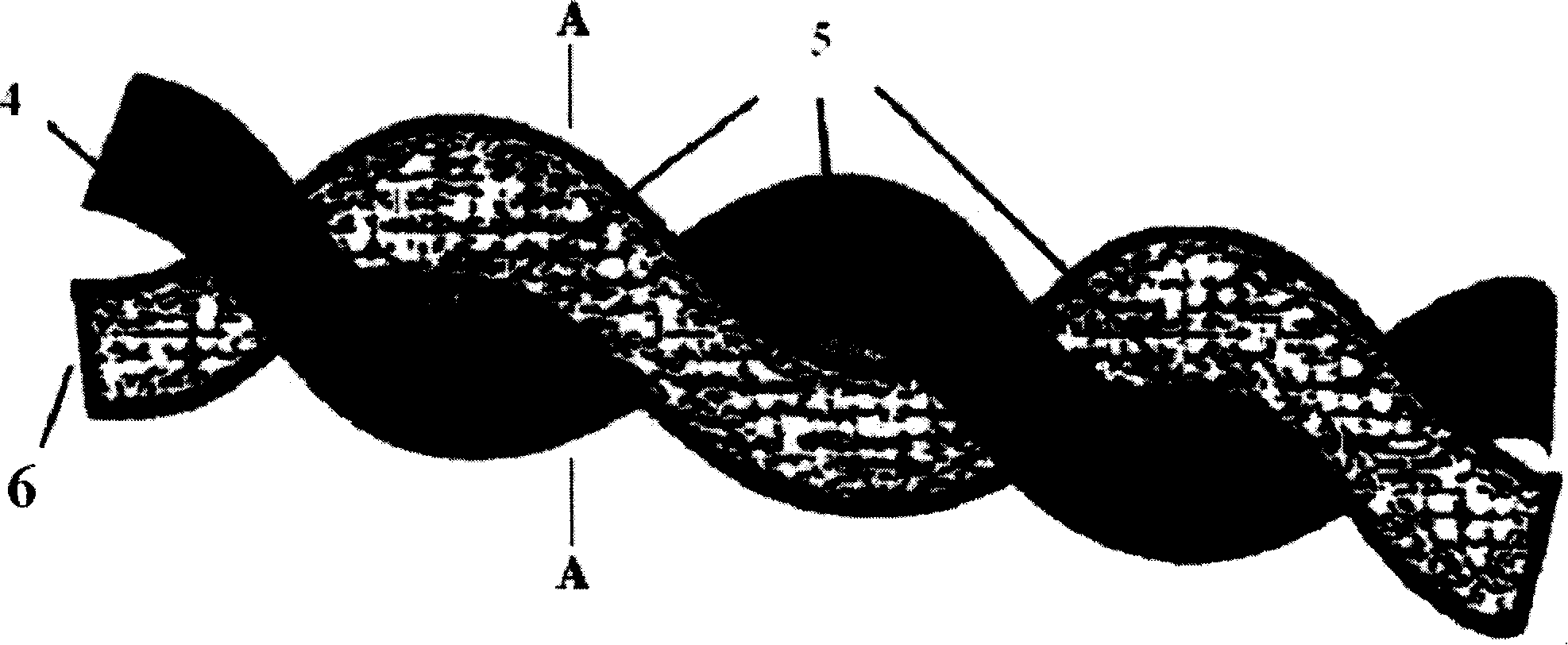

[0024] Such as figure 1 , figure 2 As shown, the working electrode of the dye-sensitized solar cell includes a conductive filamentary matrix 1 and a sensitized semiconductor film 2. The sensitized semiconductor film 2 is a porous film structure composed of semiconductor particles of different sizes that adsorb sensitized dye molecules. The chemical semiconductor thin film 2 is wrapped on the outer surface of the conductive filamentary substrate 1.

[0025] The preparation method of the sensitized semiconductor film in the working electrode of the dye-sensitized solar cell is as follows: multiple times of spraying and sintering the semiconductor material on the conductive filamentary substrate, and placing the conductive filamentary substrate with the sintered semiconductor material in the dye-sensitized can be converted.

[0026] The semiconductor material is any semiconductor material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com