Grate bar and grate for a step-grate stoker

A furnace bar and grate technology, which is applied in the field of furnace bars and grates used for step-by-step grate stokers, can solve the problem of expanding the interval between furnace bars, failing to fully prevent the continuous accumulation of refractory materials, and increasing the difficulty of adjusting combustion and other issues, to achieve the effect of reducing risks, effective and well-distributed combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

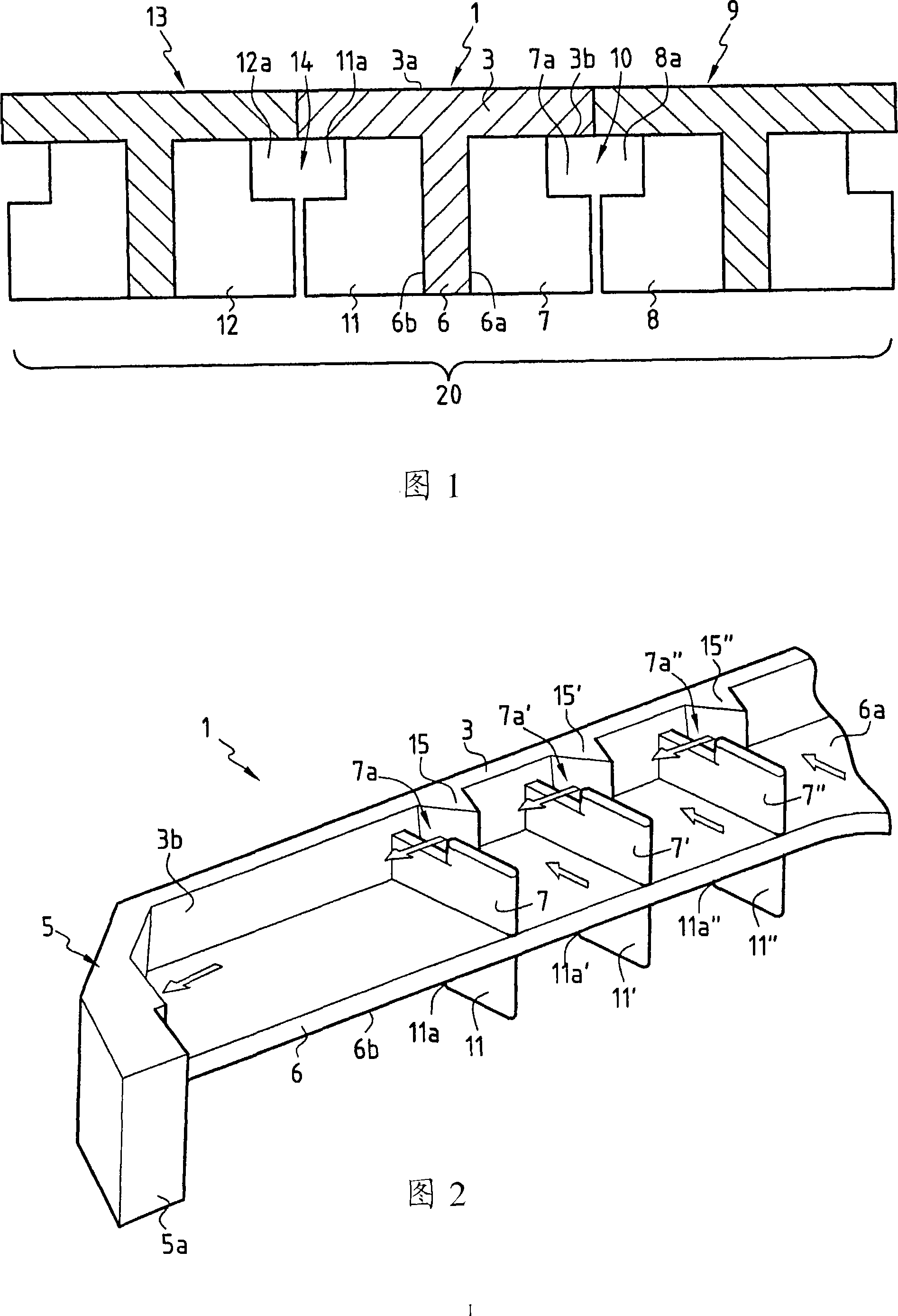

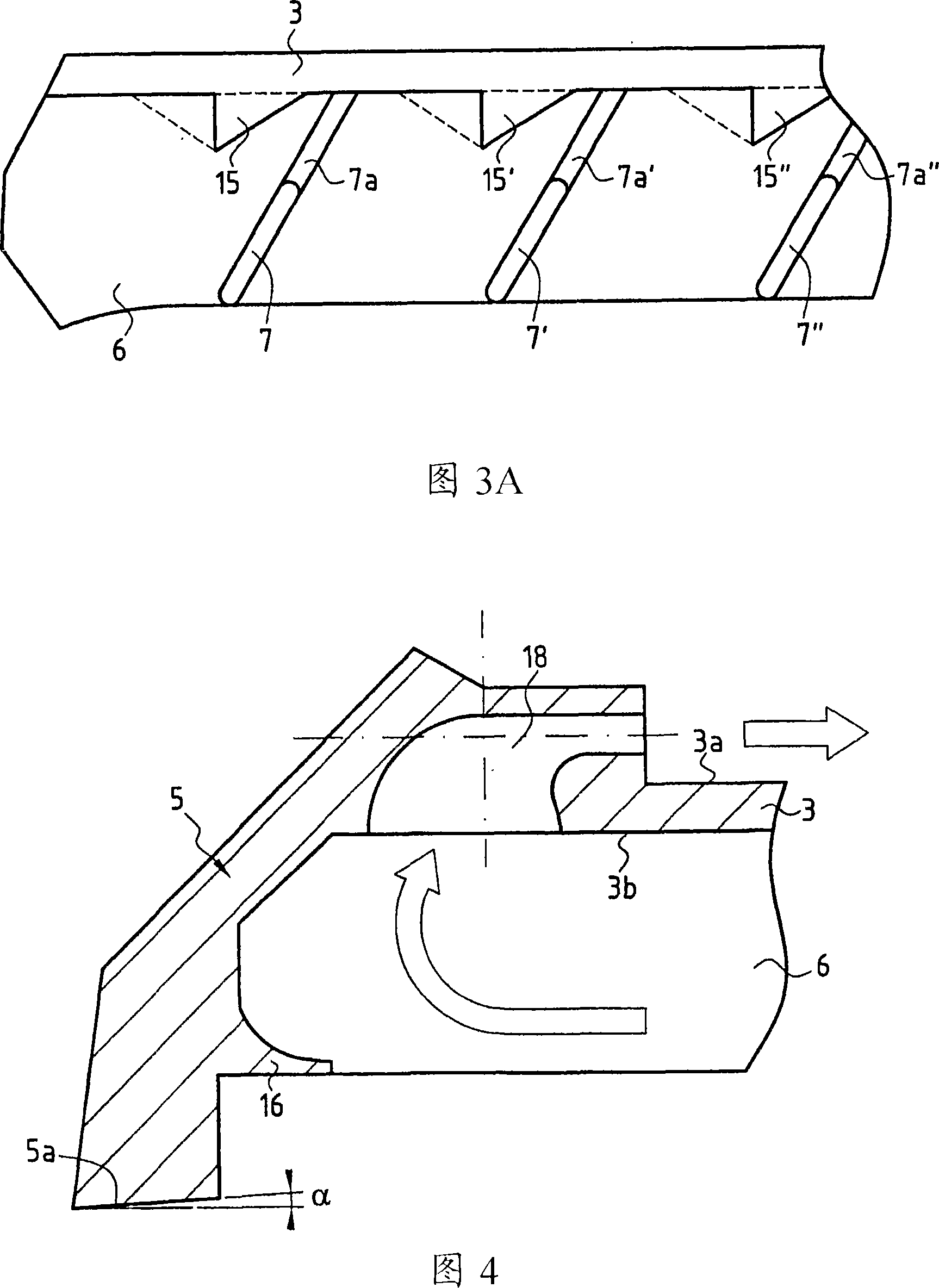

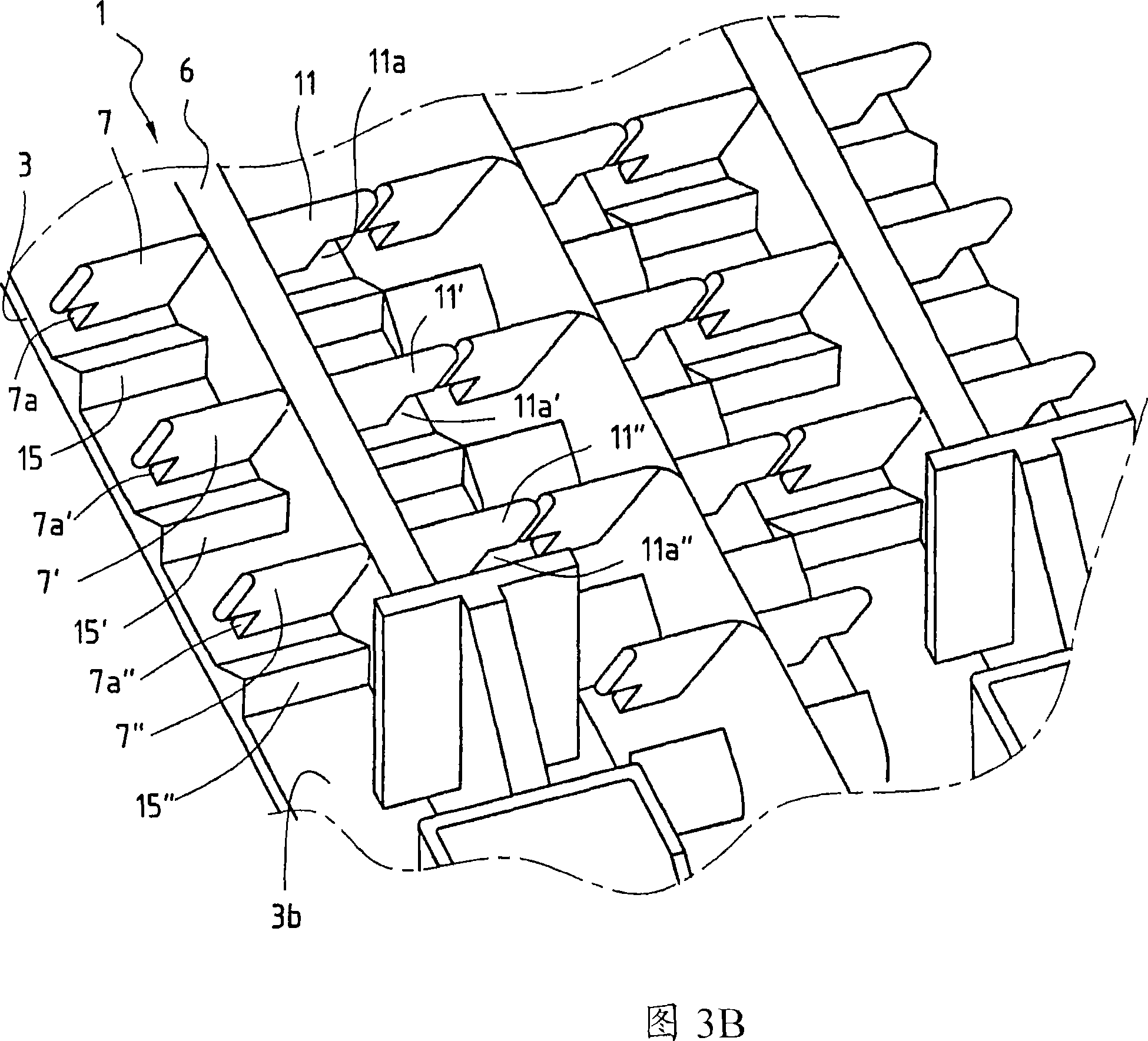

[0045] Figure 1 schematically shows a cross-sectional view of a set of three bars according to the invention.

[0046] In this figure three bars 1 , 9 , 13 are shown. It can be observed that the main part of each bar is "T" shaped, as in the case of bar 1 , with the flat part 3 atop the longitudinal projection 6 . Among other advantages, this "T" shaped main part, due to its moment of inertia, offers a preferred level of geometrical and mechanical precision, as well as a better resistance to deformation at high temperatures.

[0047] The materials used are preferably refractory alloys with high resistance to thermal wear, thermal corrosion, oxidation and thermal shock. Cast manufacturing methods allow the realization of such high fusion and high melting point alloys. The "T" shaped main part, fully removable from its mold, allows the use of a "natural" casting method which has the particular advantage of being considerably easier than other more complex casting methods.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com