Method for making surface pattern by employing water transfer printing

A technology of surface pattern and water transfer printing, which is applied in the fields of crafts, decorative arts, and preserved paintings for producing decorative surface effects, and can solve the problems of insufficient flatness of the film, troublesome pattern making, and graphic deformation, etc., to achieve clear and flat patterns , good transfer effect, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

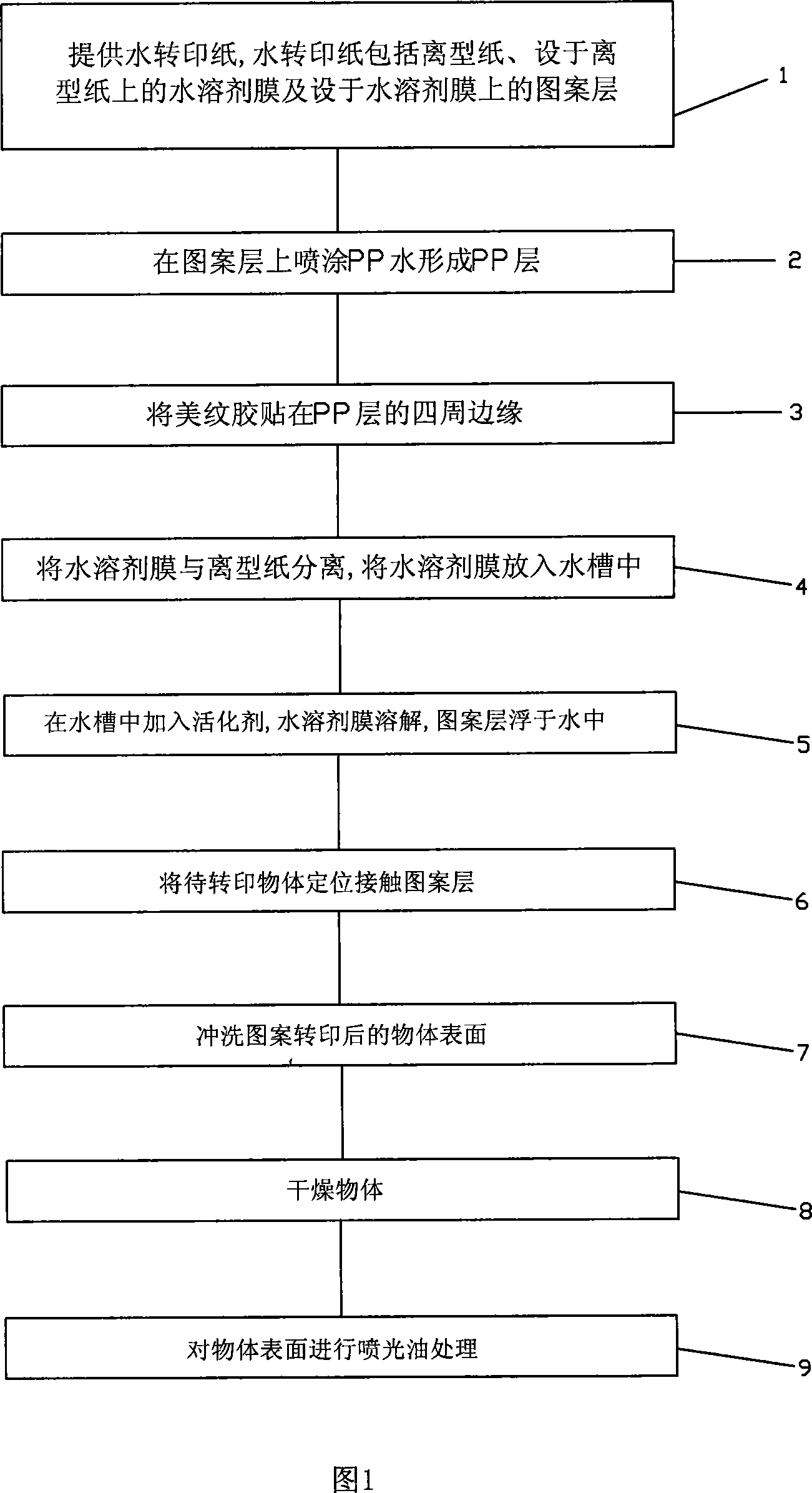

[0020] FIG. 1 is a flow chart of the method for making surface patterns by water transfer printing according to the present invention. The method includes the following steps:

[0021] Step 1: provide water transfer paper; the water transfer paper includes release paper, a water solvent film arranged on the release paper and a pattern layer arranged on the water solvent film;

[0022] The release paper is made of peelable plastic paper, which is used as the carrier of the water solvent film.

[0023] The water solvent film is made of synthetic resin with good water solubility by extrusion molding, calendering molding or tape casting; then the water solvent film is pressed on the release paper; the water solvent film and the release paper are covered by the film Machine lamination or manual lamination and set together.

[0024] The designed pattern is printed or printed on the water solvent film to form a pattern layer; if the printed or printed ink is water-soluble, a stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com