Method for preparing in-situ self-toughening alumina ceramics

A self-toughening technology for alumina ceramics, applied in the field of preparation of in-situ self-toughened alumina ceramics, can solve the problem of high cost and achieve simple and controllable equipment and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

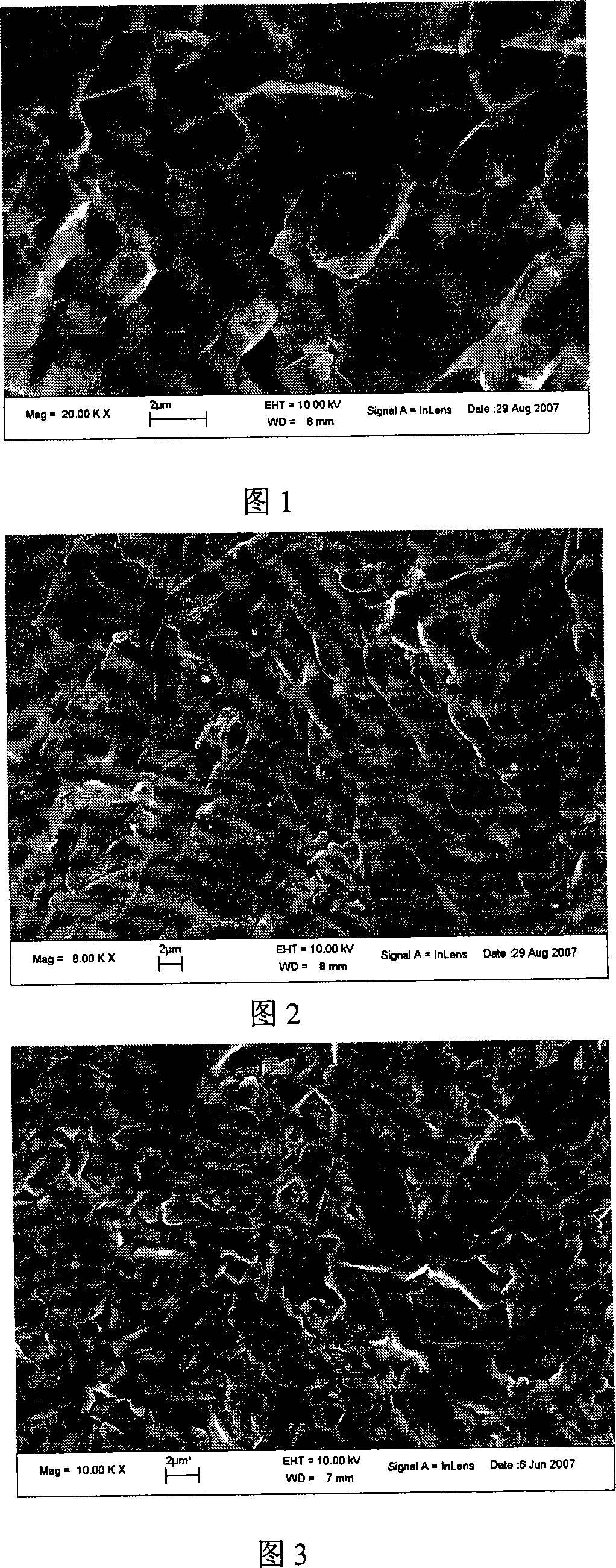

[0026] Weigh the initial raw material 40g Al 2 o 3 and 0.004g Al powder into a nylon resin ball mill jar, use alumina balls with a purity of 99%, add polyethylene glycol with a mass fraction of alumina powder of 1‰ and 250mL alcohol, and perform wet ball milling in a high-energy ball mill for 8 hours . Put the mixture after high-energy ball milling into a 99% alumina ceramic crucible, dry it in an oven at 50°C to obtain a uniformly mixed powder, shape it with various molding methods, and sinter it at 1550°C in an ordinary sintering furnace under an air atmosphere. Hours, a single-phase alumina ceramic with in-situ growth of long columnar and plate-like crystals is obtained, and its typical structure is shown in Figure 1. It can be seen from Figure 1 that the prepared alumina ceramic grains have appeared plate-shaped crystals or long columnar crystals with an aspect ratio greater than 2.

Embodiment 2

[0028] Weigh the initial raw material 40g Al 2 o 3 and 0.02g Al powder into a nylon resin ball mill jar, use alumina balls with a purity of 99%, add polyethylene glycol with a mass fraction of alumina powder of 5‰ and 250mL alcohol, and perform wet ball milling in a high-energy ball mill for 10 hours . Put the mixture after high-energy ball milling into a 99% alumina ceramic crucible, and dry it in an oven at 50°C to obtain a uniformly mixed powder, which is formed by cold isostatic pressing and sintered at 1580°C in an ordinary sintering furnace under an air atmosphere. Hours, a single-phase alumina ceramic with in-situ growth of long columnar and plate-like crystals was obtained, and its typical structure is shown in Figure 2. It can be seen from Figure 2 that there are long columnar and plate-shaped crystals with a large area as shown by the arrows. These irregularly grown grains form a certain degree of interpenetrating network structure. The longest grain aspect ratio i...

Embodiment 3

[0030] Weigh the initial raw material 40g Al 2 o 3 and 0.04g Al powder into a nylon resin ball mill jar, use alumina grinding balls with a purity of 99%, add polyethylene glycol with a mass fraction of alumina powder 1% and 250mL alcohol, and perform wet ball milling in a high-energy ball mill for 12 hours . Put the mixture after high energy ball milling into a 99 alumina ceramic crucible, dry it in an oven at 50°C to obtain a uniformly mixed powder, shape it by injection molding, and sinter at 1560°C for 3 hours in an ordinary sintering furnace under an air atmosphere , to obtain single-phase alumina ceramics with in-situ growth of long columnar and plate-like crystals, the typical structure of which is shown in Figure 3. It can be seen from Figure 3 that there are long columnar and plate-like crystals with a large area. As shown by the arrows, these irregularly grown grains form a certain degree of interpenetrating network structure. The longest grain aspect ratio is great...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com