Modified cordierite porous ceramic material and preparation method and application thereof

A technology of porous ceramics and cordierite, applied in chemical instruments and methods, silicates, inorganic chemistry, etc., can solve the problems of high cost and poor removal ability of low-concentration heavy metal ions, and achieve low production cost and high mechanical strength. , The effect of wide adaptability of chemical adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

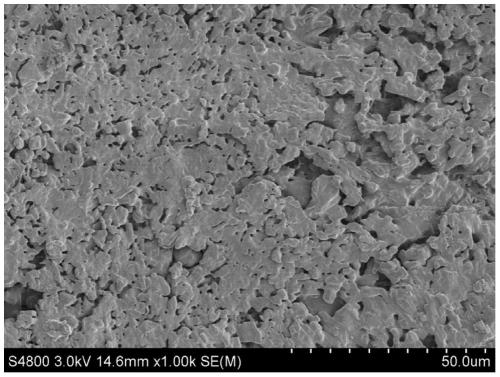

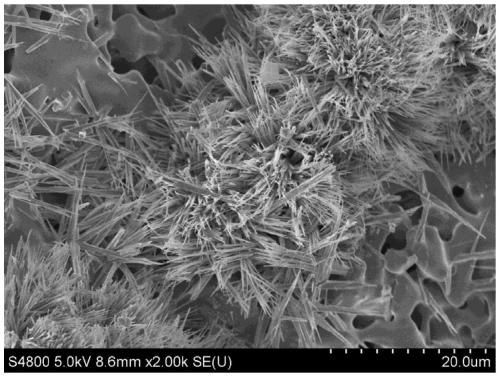

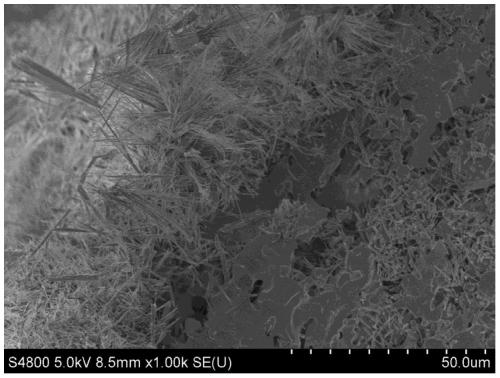

Image

Examples

preparation example Construction

[0041] This embodiment also provides a method for preparing a modified cordierite porous ceramic material, which specifically includes the following steps:

[0042] Step 1, weighing aluminum sulfate, silicon source and sulfate according to the formula, fully grinding, sieving, and regrinding to obtain a mixed powder; covering the obtained mixed powder on the cordierite ceramic block of the formula and heating to react;

[0043] Step 2, boiling the product obtained in Step 1 in a boiling water bath until the molten salt remaining on its surface is completely dissolved, then cooling, washing, and drying to obtain cordierite-mullite whiskers;

[0044] Step 3, in the cordierite-mullite whisker that step 2 obtains, add the solvent of formula quantity and silane coupling agent, carry out reaction;

[0045] In step four, the product obtained in step three is naturally cooled and washed to obtain a modified cordierite porous ceramic material.

[0046] The temperature rise rate of the...

Embodiment 1

[0059] This example provides a modified cordierite porous ceramic material and its preparation method. The modified cordierite porous ceramic material includes the following raw materials in parts by weight: 12 parts of aluminum sulfate, 3 parts of silicon source, 85 parts of molten salt, cordierite 10 parts, 80 parts of solvent and 10 parts of silane coupling agent.

[0060] The preparation method of the modified cordierite porous ceramic material, the method specifically includes the following steps:

[0061] Step one, the Al 2 (SO4) 3 18H 2 O was sintered in a muffle furnace at 400°C for 3 hours to remove crystal water to obtain anhydrous aluminum sulfate; weigh aluminum sulfate, diatomaceous earth and potassium sulfate according to the formula, fully grind, sieve, and regrind to obtain a mixed powder ; Cover the obtained mixed powder on the cordierite ceramic block with the formula amount at the bottom of the corundum crucible and heat it for reaction, raise it to 1000°...

Embodiment 2

[0067] This example provides a modified cordierite porous ceramic material and its preparation method. The difference between this example and Example 1 is that the modified cordierite porous ceramic material includes the following raw materials in parts by weight: 12 parts of aluminum sulfate, silicon 3 parts of source, 85 parts of molten salt, 20 parts of cordierite, 70 parts of solvent and 10 parts of silane coupling agent.

[0068] The difference between the preparation method of the modified cordierite porous ceramic material in this example and Example 1 is that in step 1: in the muffle furnace, the temperature is raised to 900°C at a rate of 5°C / min, and the temperature is kept at the highest temperature for 2h ; In step three, react at 60° C. for 24 hours; in step four, wash with absolute ethanol or acetone for 5 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com