Special type latex paper production method

A production method and technology of latex paper, applied in pulp beating method, paper, papermaking and other directions, can solve the problems of inability to complete continuous production and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The present invention is further described below, but not limiting the present invention.

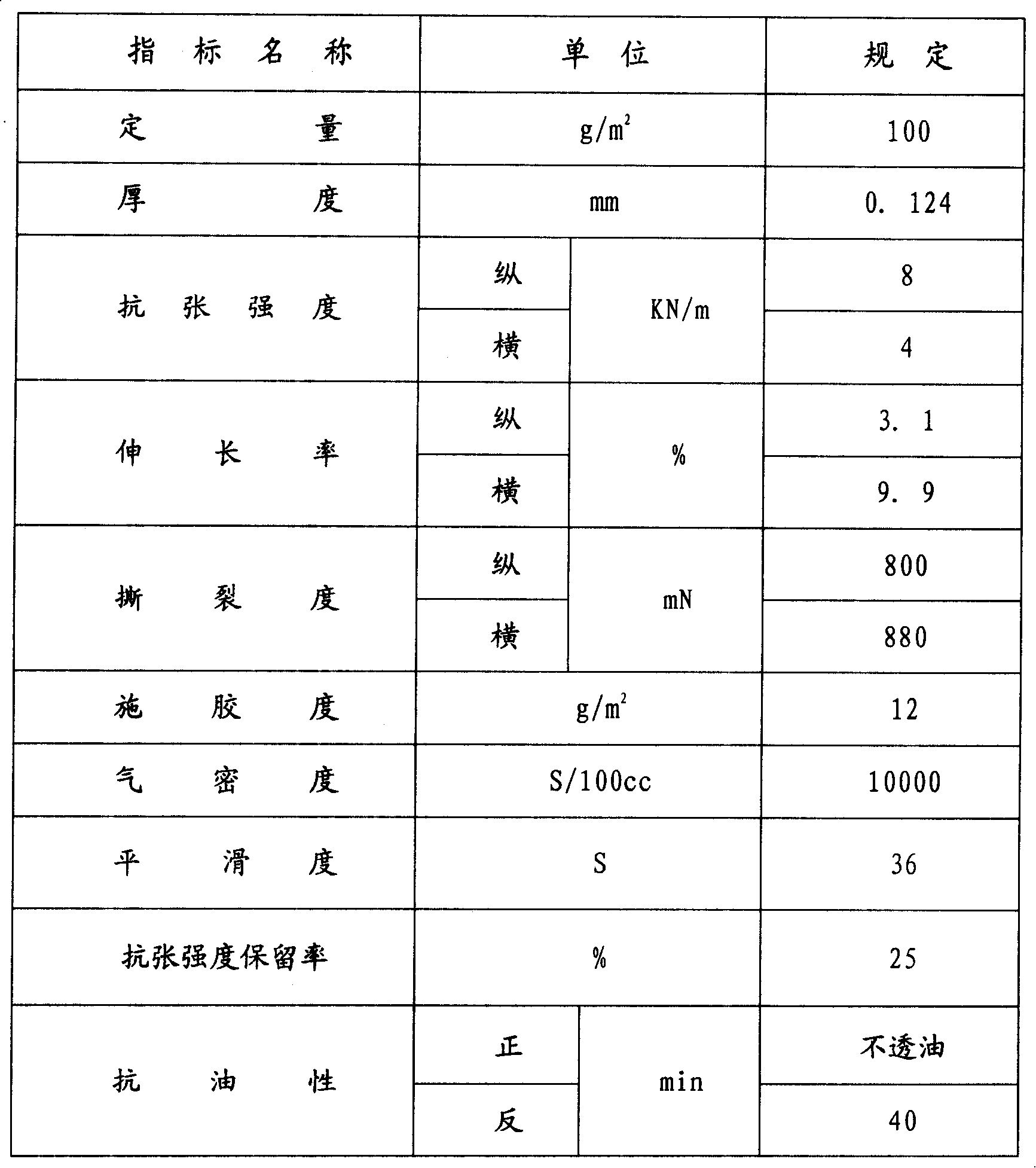

[0007] The production process of TJ-1 special latex paper base paper of the present invention:

[0008] The main raw material is bleached kraft pulp board with a content of 100%, and the following are added according to the weight percentage: 10%-12% light calcium, and water, which are pulped by a hydraulic pulper, and then enter the pre-grinding pool, and pass through the double disc Refining with a mill, and then enter the pulp tank, add 0.4%-0.6% PAE into the pulp tank, then pump into the pulp mixing box, add 0.3%-0.5% AKD and 0.3%-0.5% waterproof and oil-repellent agent, and then enter the degreaser The slag is removed by the slag machine, and then 0.1%-0.2% dye retention aid is added after the slag removal, and then enters the screen section, press section and drying section through the pulp pump and rotor screen, and then enters the drying section and calendering after surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com