Axail air gap type electric motor

A technology of axial air gap and motor, which is applied in electric components, synchronous motors with stationary armatures and rotating magnets, electromechanical devices, etc., can solve the problem of small size and light weight, unavoidable large stator and increased loss and other problems, to achieve the effect of improving torque, preventing magnet rotation, and reducing resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

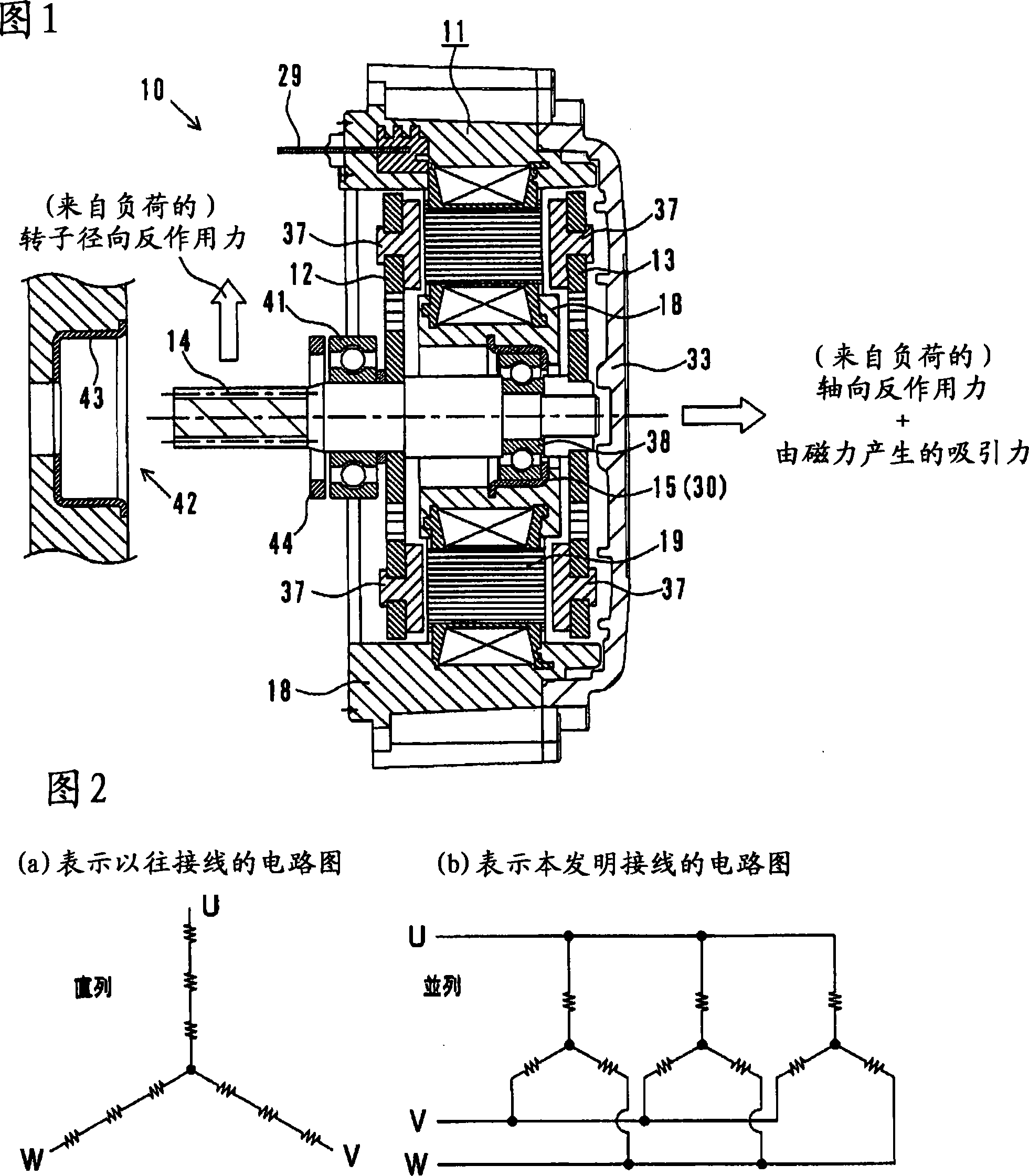

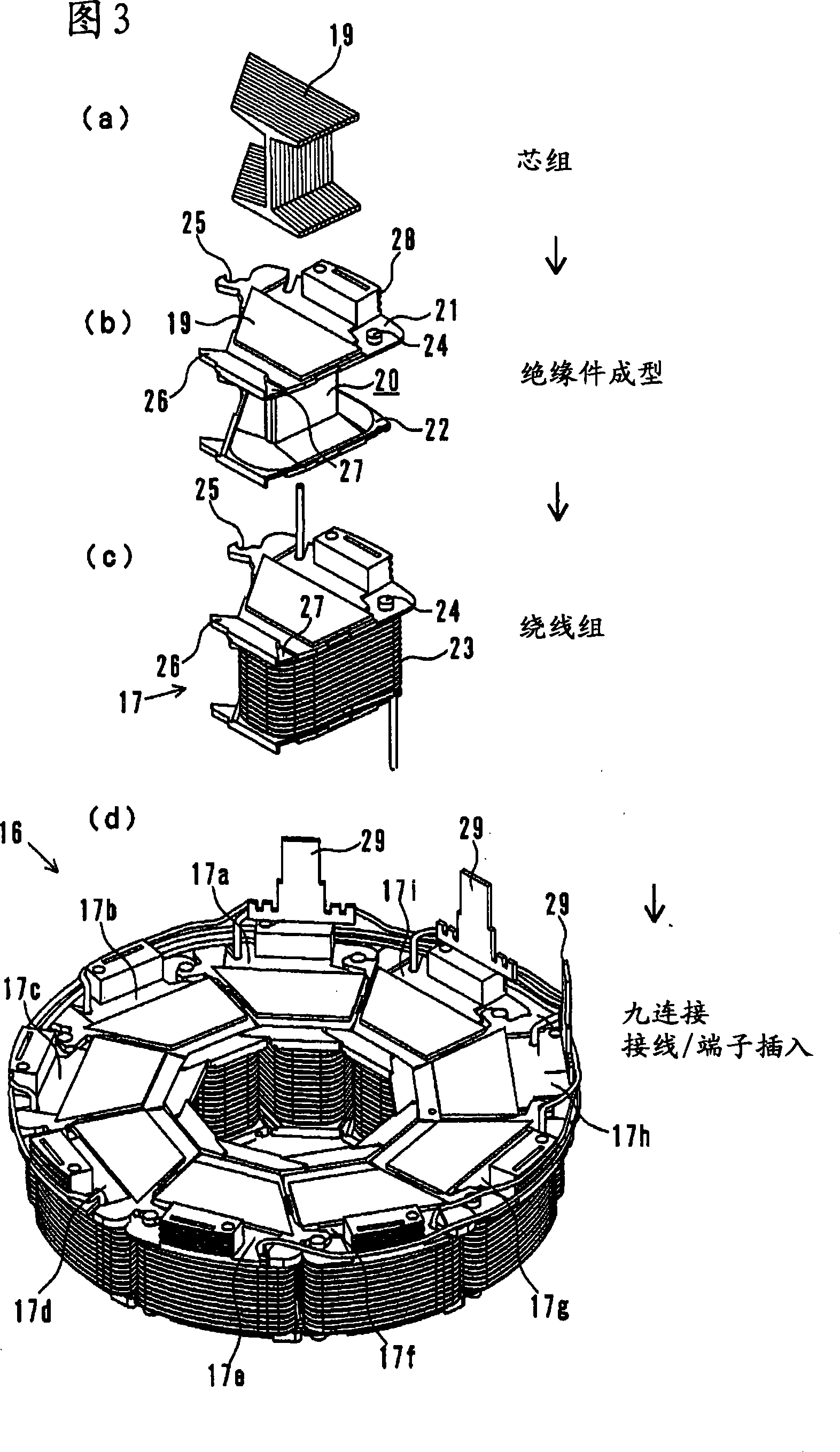

[0034] Embodiments of the present invention will be described with reference to the drawings. FIG. 1 is a cross-sectional view schematically showing the internal structure of an axial air gap motor according to the present invention. As shown in FIG. 1 , an axial air-gap motor 10 includes a substantially disk-shaped stator 11 and a pair of rotors 12 and 13 disposed opposite to each other with a predetermined gap on both sides of the stator 11. The rotors 12 and 13 The same rotor output shaft 14 is shared, and the stator 11 has a bearing portion 15 for supporting the rotor output shaft 14 on its inner peripheral side.

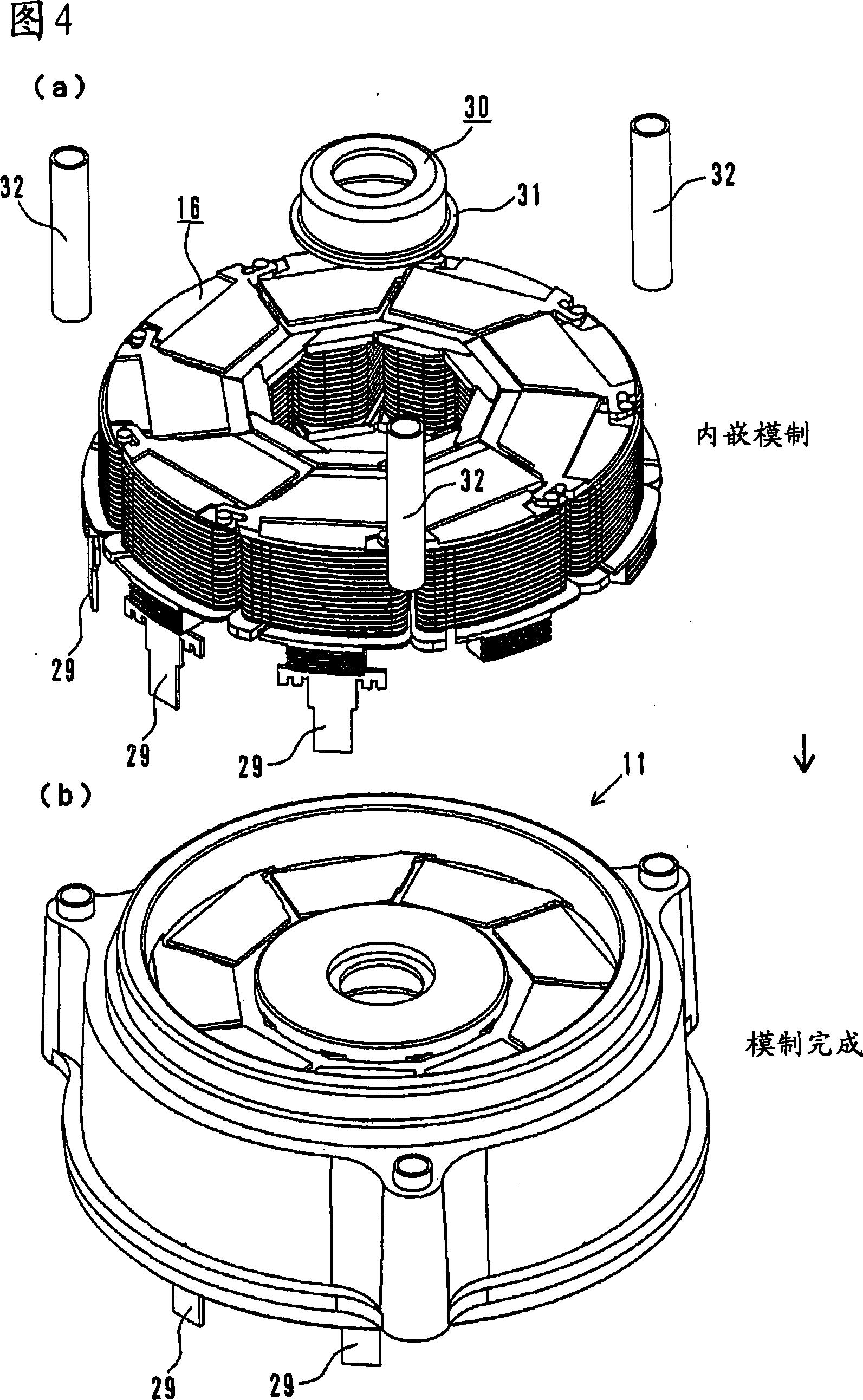

[0035] The stator 11 includes a ring-shaped (so-called toroidal) stator core 16 and a bearing portion 15 coaxially inserted into the inner peripheral side of the stator core 16 , which are integrally molded from a synthetic resin 18 .

[0036] In addition, in this description, when a bearing part is shown, it means the whole structure which fixes a shaft includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com