Solid-state laser device

A solid-state laser, laser light source technology, applied in lasers, solid-state laser parts, laser parts and other directions, can solve the problems of base material damage, laser transmittance decline, coating damage, etc., to improve reliability, prevent optical Effects of component aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

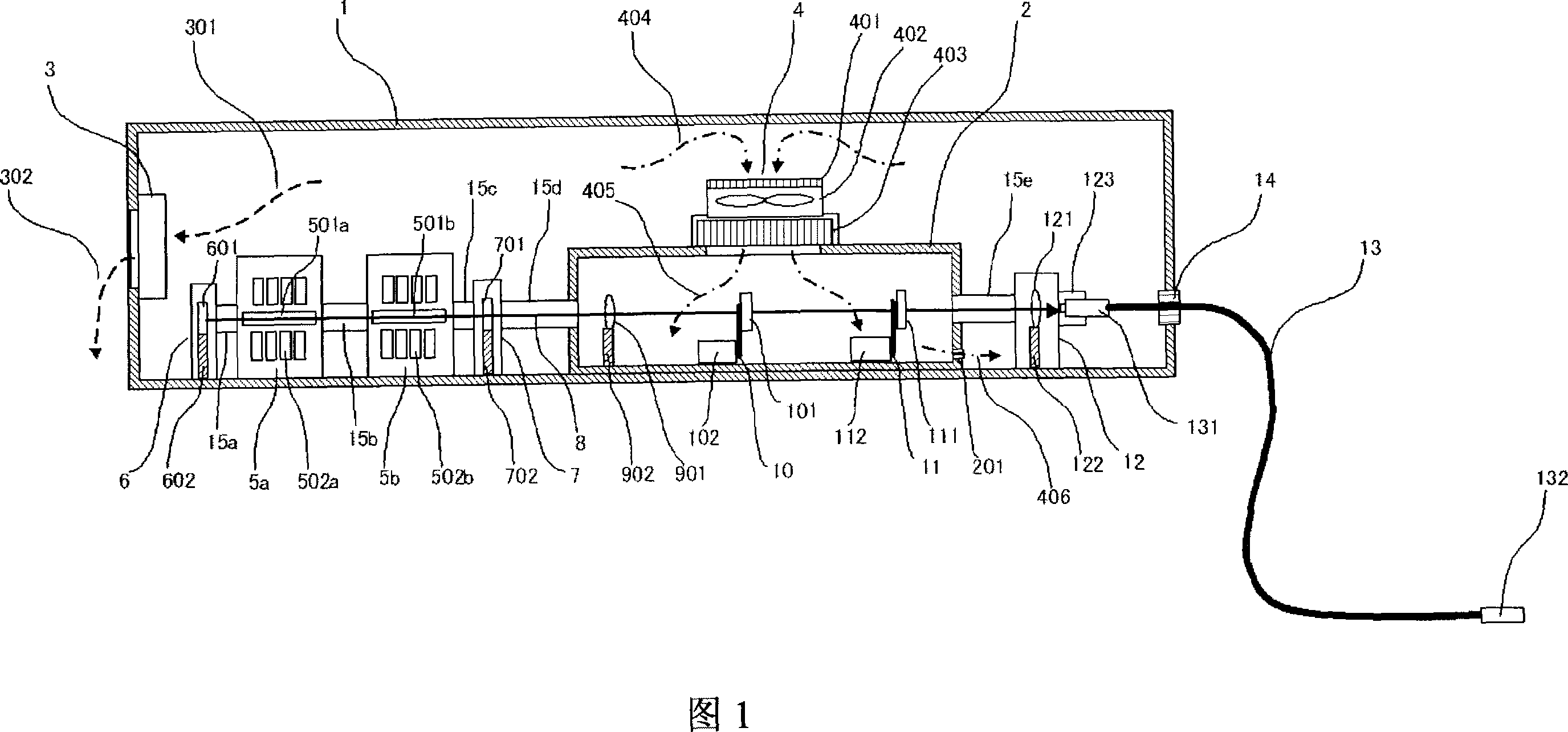

[0020] FIG. 1 is a schematic diagram showing the configuration of a solid-state laser device in Embodiment 1 of the present invention. In FIG. 1 , 1 is an external case having a substantially sealed structure, which also serves as a protective case for preventing leakage of laser light and scattered light to the outside. Here, the substantially airtight structure refers to a structure having airtightness of IP 21 to IP 56 or an equivalent level based on the foreign matter entry level specified in IEC Standard 529 (the same applies below). 2 is an inner case disposed inside the outer case 1 . 3 is a dehumidifier installed on the side wall surface of the outer case 1 as a dehumidification unit, and discharges moisture in the outer case 1 to the outside of the outer case 1 . 301 and 302 are dotted lines schematically showing the water 301 inside the outer case 1 and the water 302 discharged out of the outer case 1 . In addition, in the present embodiment, "SP dehumidifier port ...

Embodiment approach 2

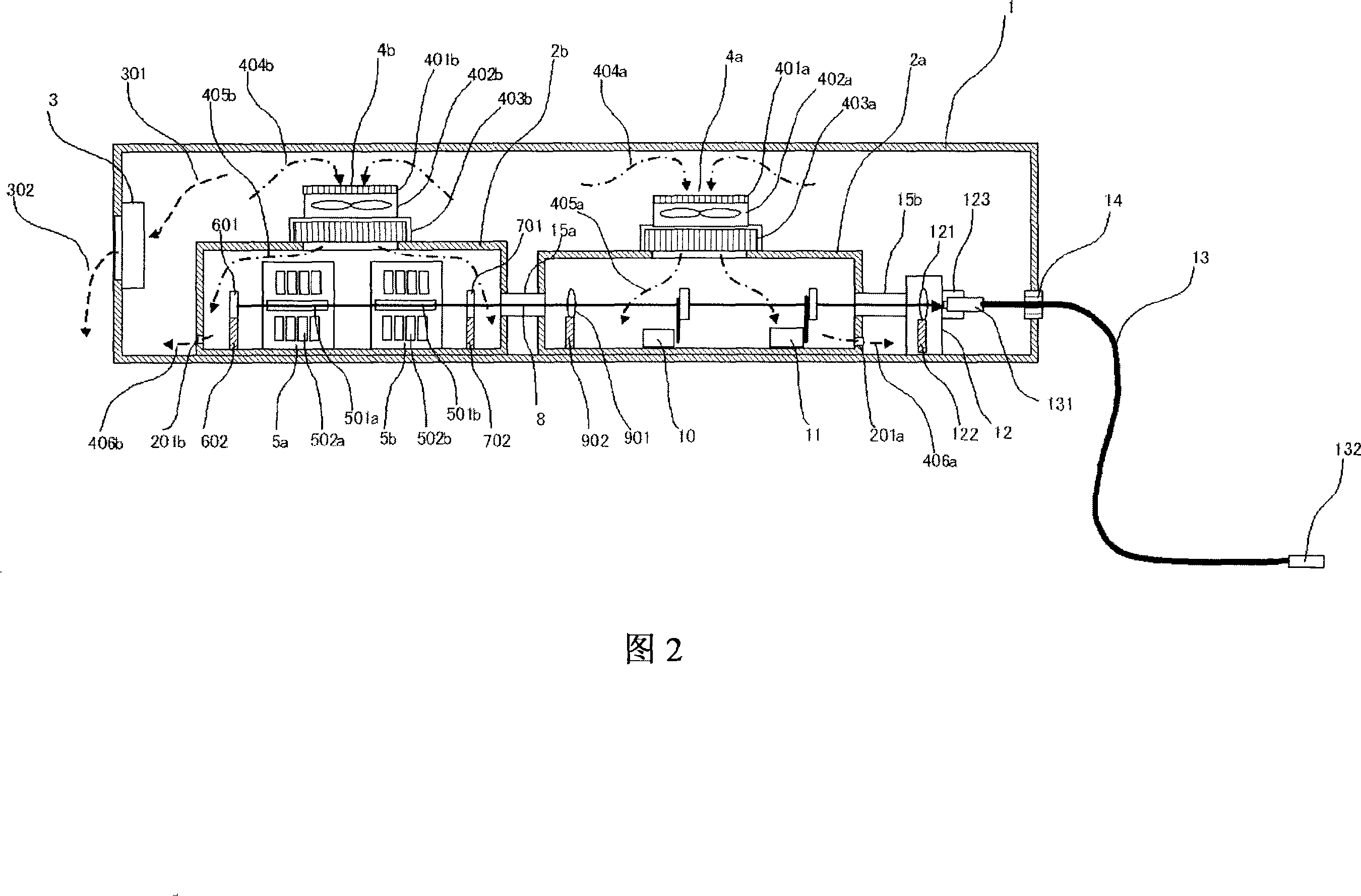

[0029] FIG. 2 is a schematic diagram showing the configuration of a solid-state laser device according to Embodiment 2 of the present invention. In this embodiment, two inner cases 2a and 2b are provided in a single outer case 1 having a substantially airtight structure. In the first inner casing 2a, the collimator lens 901, the intermediate light shielding unit 10, and the safety light shielding unit 11 are arranged in the same manner as in the above-mentioned first embodiment. In addition, a laser light source including two resonator units 5 a and 5 b , a total reflection mirror 601 , and a partial reflection mirror 701 is arranged in the second inner casing 2 b.

[0030] As shown in this embodiment, since a plurality of inner casings 2a, 2b are provided in a single outer casing 1, not only the same effect as that of the above-mentioned first embodiment can be obtained, but also by arranging the inner casing 2b Resonant cavity unit 5a, 5b, not only can reduce the requiremen...

Embodiment approach 3

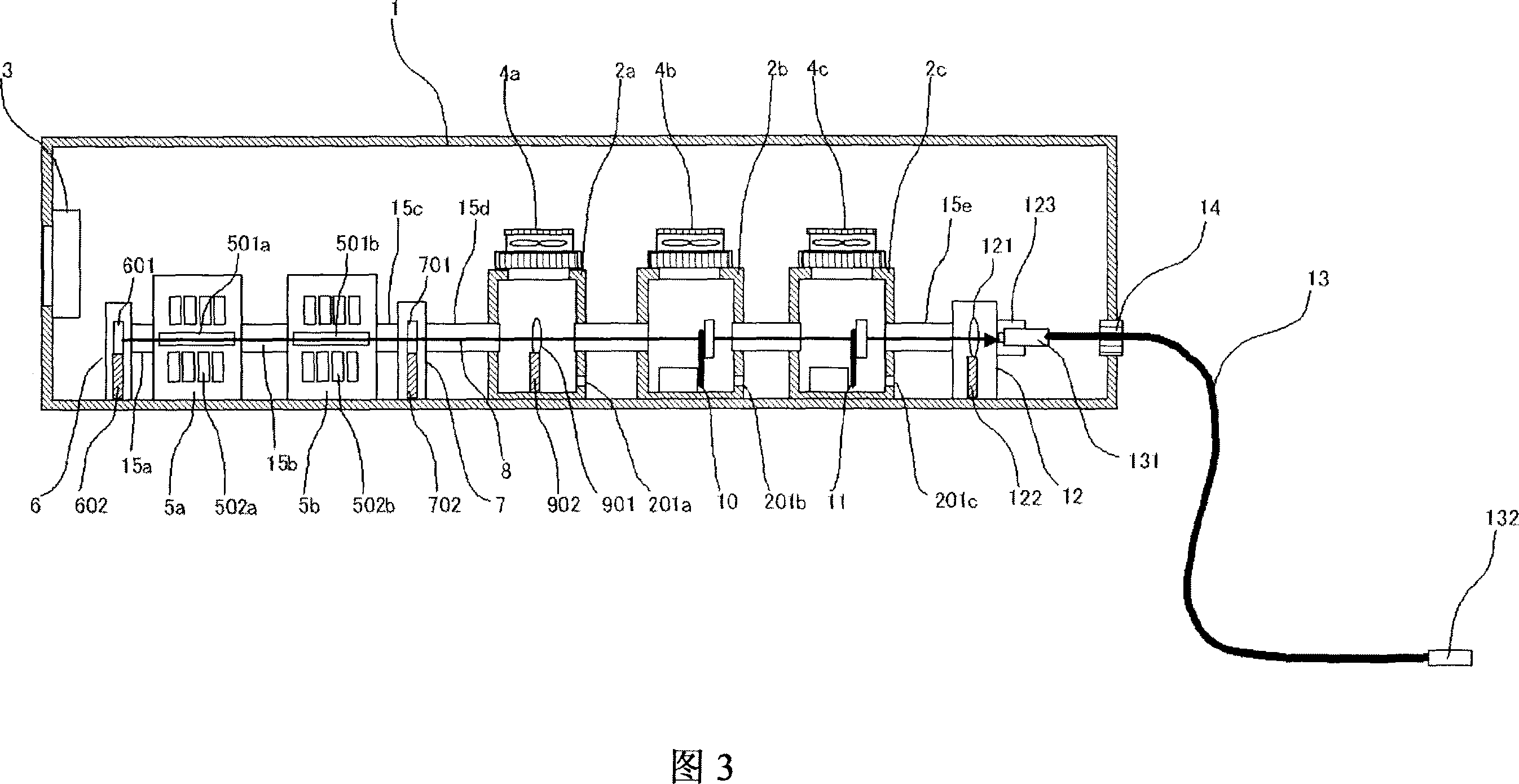

[0035] 3 is a schematic diagram showing the configuration of a solid-state laser device in Embodiment 3 of the present invention. In this embodiment, internal housings 2a, 2b, 2c are provided for collimator lens 901, intermediate light shielding unit 10, and safety light shielding unit 11 constituting the optical system unit for transmitting laser light 8 to optical fiber 13, respectively. According to this embodiment, not only can the same effect as that of the above-mentioned Embodiment 1 and Embodiment 2 be obtained, but also since the inner casings 2a, 2b, and 2c are provided for each unit, when performing maintenance work on each unit, it only needs to be opened as The inner case 2 of the target unit part is enough, so the risk of dust and the like entering into the inner case 2 of other units can be effectively reduced, and the reliability can be further improved.

[0036] In addition, in this embodiment, the collimator lens 901, the intermediate light-shielding unit 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com