Method for preparing four kinds of theaflavin monomer

A technology of theaflavins and monomers, which is applied in the field of preparing theaflavins monomers, can solve problems such as difficult amplification, inability to be suitable for large-scale industrial production, and separation, and achieve the effect of improving utilization and being suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

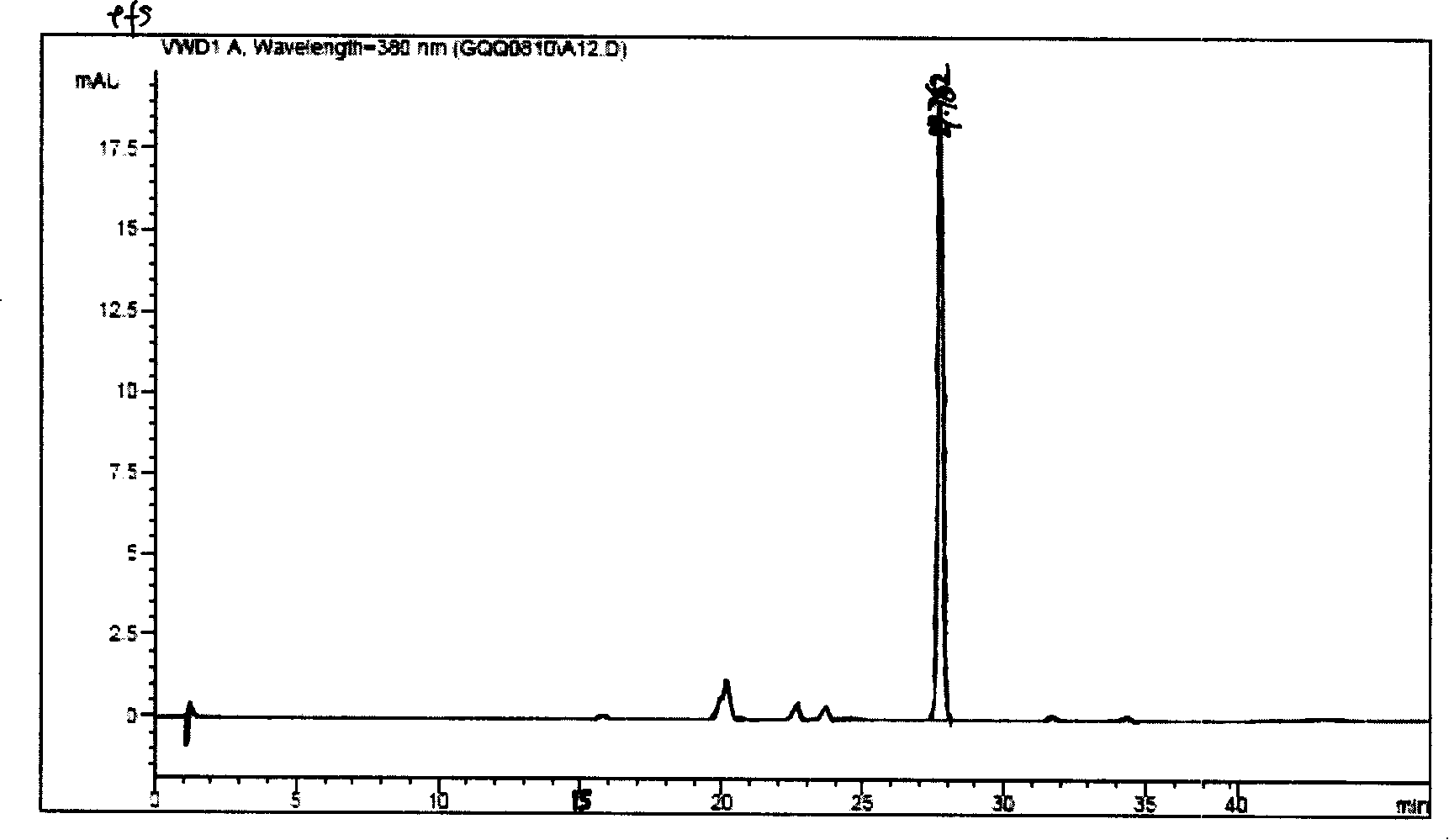

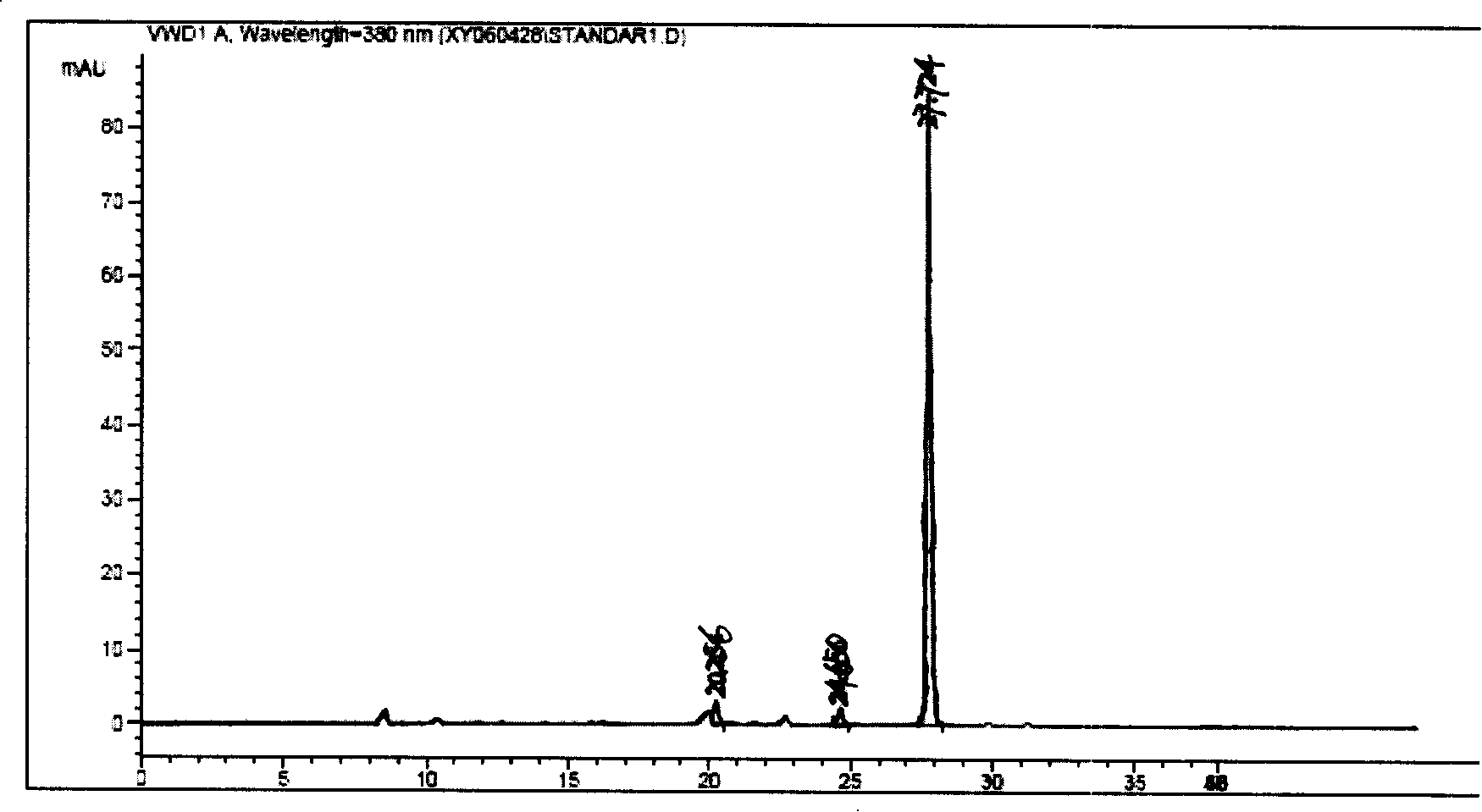

[0026] The theaflavin extracts on the market (the total content of the four theaflavins of TF, TF-3-G, TF-3'-G and TFDG is 40%) are used as raw materials. Weigh 2g of theaflavin extract and dissolve it in 20ml of water as the loading solution.

[0027] The polyamide resin with a particle size of 80-100 objects is filled into a test-scale column with a diameter of 20mm and a length of 800mm. The volume of the packed column bed is 180ml. The column is equipped with a heating mantle, and the resin is filled with water, 5% NaOH aqueous solution, and Water, 10% acetic acid aqueous solution, water, 95% ethanol and water are washed to remove various impurities contained.

[0028] The packed column was kept at a constant temperature of 20°C, and the column solution was loaded onto the top of the polyamide resin. At a temperature of 20°C, use a mixed solvent of ethyl acetate:ethanol:acetic acid=6:2:3 to elute various theaflavins from the column at a constant flow rate of 2BV (column b...

Embodiment 2

[0031] The mixed solvent in Example 1 is replaced by methyl isoamyl ketone: ethanol: acetic acid=6: 2: 3, and the operation in Example 1 is repeated to obtain four sections of eluate, after drying, wherein theaflavin ( TF) purity is 97%, theaflavin-3-gallate (TF-3-G) purity is 93%, theaflavin-3'-gallate (TF-3'-G) purity is 96% , Theaflavin digallate (TFDG) purity is 98%.

Embodiment 3

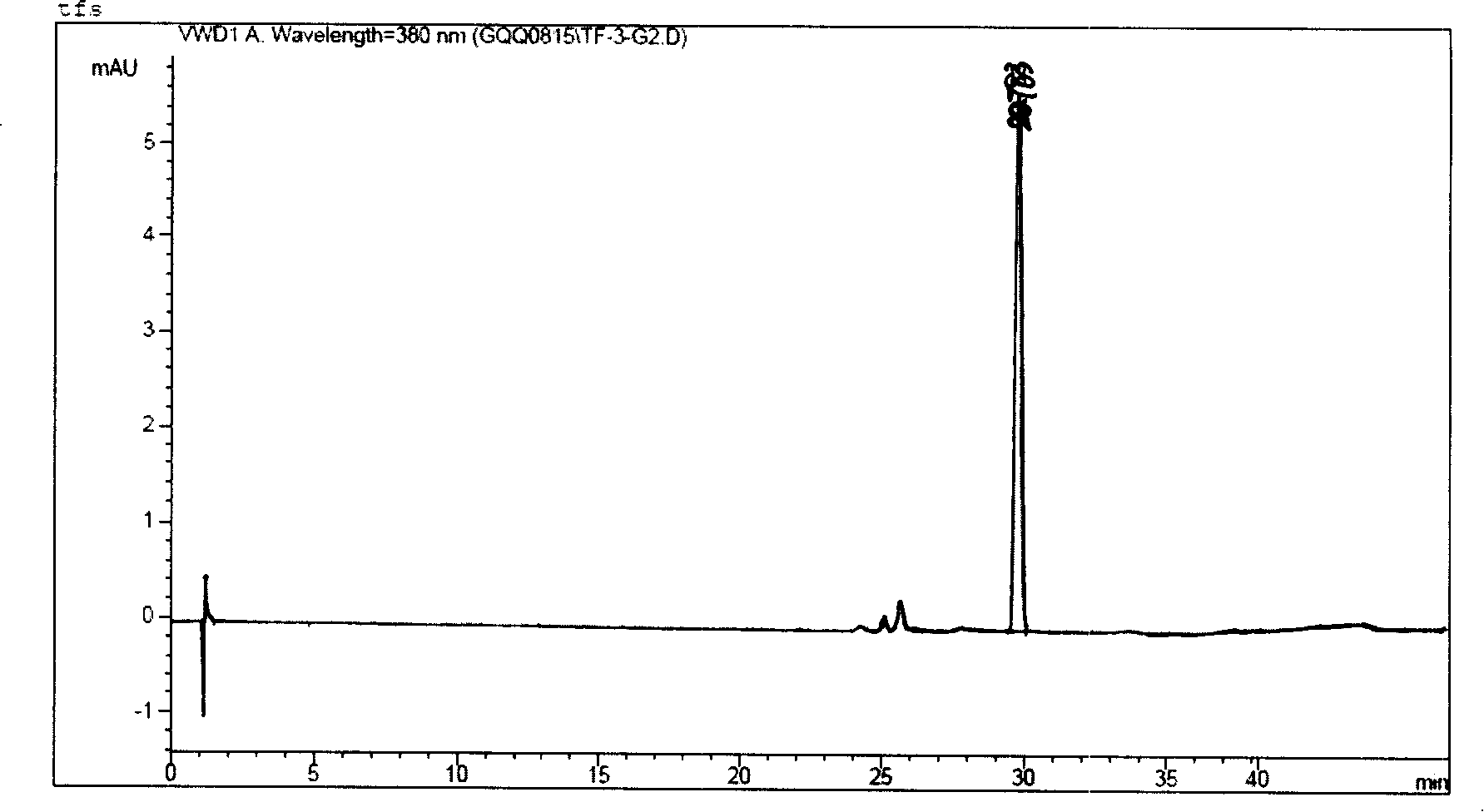

[0033]The theaflavin extracts on the market (the total content of the four theaflavins of TF, TF-3-G, TF-3'-G and TFDG is 60%) are used as raw materials. Weigh 4g of theaflavin extract and dissolve it in 20ml of water as the loading solution.

[0034] The polyamide resin with a particle size of 150-200 objects is filled into a test-scale column with a diameter of 25mm and a length of 600mm. The packed column bed volume is 215ml. The column is equipped with a heating mantle, and the resin is sequentially filled with water, 5% NaOH aqueous solution, Water, 10% acetic acid aqueous solution, water, 95% ethanol and water are washed to remove various impurities contained.

[0035] The packed column was kept at a constant temperature of 40°C, and the column solution was loaded onto the top of the polyamide resin. At a temperature of 40°C, first use a 10BV mixed solvent of ethyl acetate:ethanol:acetic acid=4:1:3 to elute at a constant flow rate of 2BV / hour through the pump, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com