Elastic polyurethane cladding non-powder rubber medical glove and method for producing the same

An elastic polyurethane and polyamic acid coating technology, applied in the field of medical supplies, can solve the problems of insufficient film density, inelasticity, and easy peeling of the coating, and achieve good biocompatibility, enhanced slippery effect, and mature preparation technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

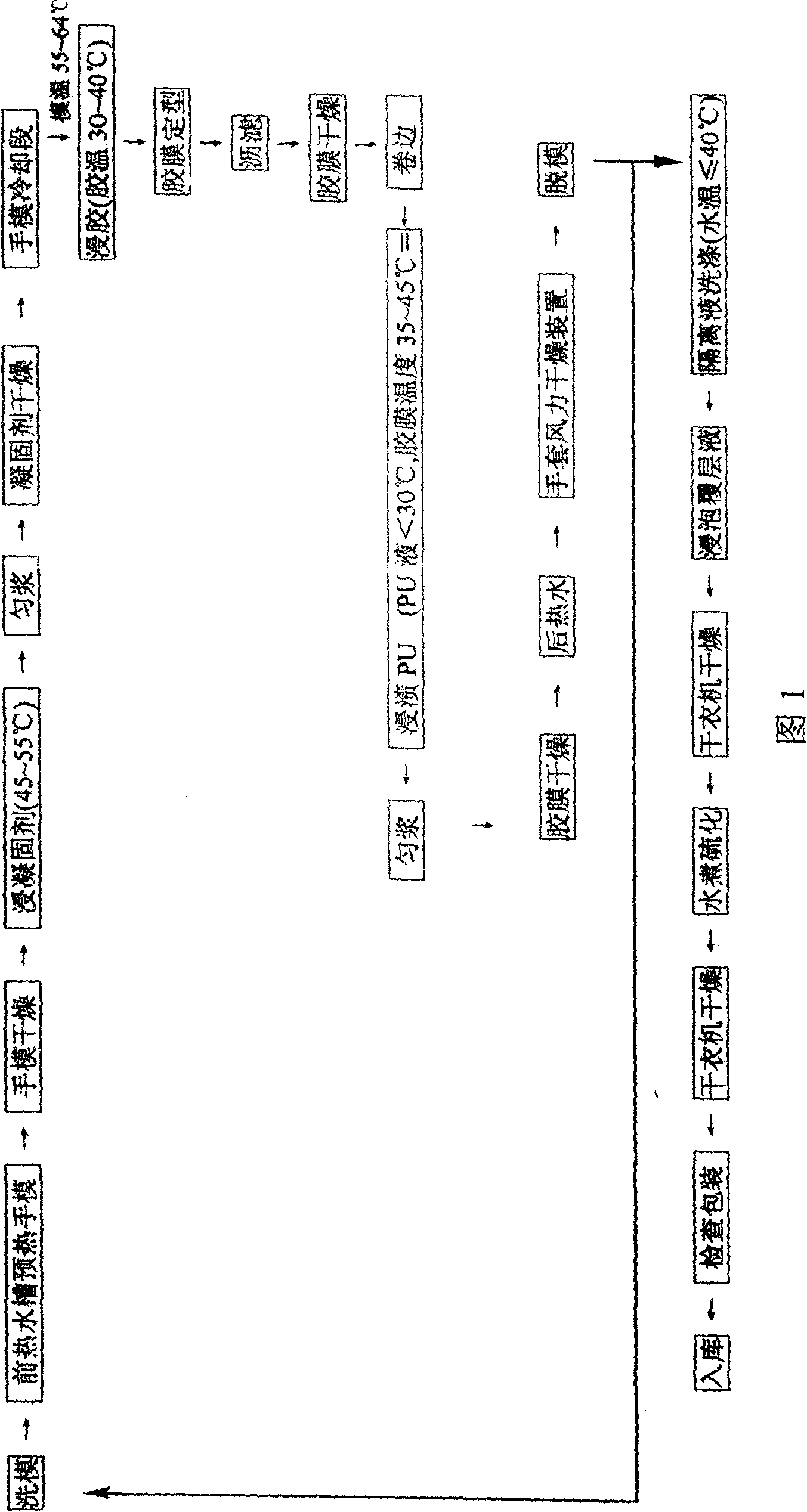

Image

Examples

Embodiment 1

[0032] The invention consists of a natural rubber glove body, an elastic polyurethane coating on the inner surface of the glove sleeve, and a modified polyacrylic acid coating on the outer surface of the glove sleeve. The preparation process includes the following steps:

[0033] 1. Prepare elastic polyurethane coating solution: Mix and stir according to the following raw materials and weight percentages, the stirring time is 10-20 hours, and the stirring speed is 60-100 rpm:

[0034] PU133-211 elastic polyurethane (30% concentration) 8.5

[0035] PHC-20 ultrafine inorganic silicon (20% concentration) 0.02

[0036] Soft water balance

[0037] 2. Preparation of modified polyacrylate coating solution:

[0038] Dilute it according to the ratio of modified polyacrylate MAX-30: soft water = 1:32 (component weight ratio), and use it after stirring for 30 minutes.

[0039] 3. Apply the elastic polyurethane cladding:

[0040] When impregnating the inner surface of the natural rubb...

Embodiment 2

[0046] The invention consists of a natural rubber glove body, an elastic polyurethane coating on the inner surface of the glove sleeve, and a modified polyacrylic acid coating on the outer surface of the glove sleeve. The preparation process includes the following steps:

[0047] 1. Prepare elastic polyurethane coating solution: Mix and stir according to the following raw materials and weight percentages, the stirring time is 10-20 hours, and the stirring speed is 60-100 rpm:

[0048] PU133-211 elastic polyurethane (30% concentration) 12

[0049] PHC-20 ultrafine inorganic silicon (20% concentration) 0.1

[0050] Soft water balance

[0051] 2. Preparation of modified polyacrylate coating solution:

[0052] Dilute it according to the ratio of modified polyacrylate MAX-30: soft water = 1:40 (component weight ratio), and use it after stirring for 30 minutes.

[0053] 3. Apply the elastic polyurethane cladding:

[0054] When impregnating the inner surface of the natural rubber g...

Embodiment 3

[0060] The invention consists of a natural rubber glove body, an elastic polyurethane coating on the inner surface of the glove sleeve, and a modified polyacrylic acid coating on the outer surface of the glove sleeve. The preparation process includes the following steps:

[0061] 1. Prepare elastic polyurethane coating solution: Mix and stir according to the following raw materials and weight percentages, the stirring time is 10-20 hours, and the stirring speed is 60-100 rpm:

[0062] PU133-211 elastic polyurethane (30% concentration) 16

[0063] PHC-20 ultrafine inorganic silicon (20% concentration) 0.14

[0064] Soft water balance

[0065] 2. Preparation of modified polyacrylate coating solution:

[0066] Dilute it according to the ratio of modified polyacrylate MAX-30: soft water = 1:40 (component weight ratio), and use it after stirring for 30 minutes.

[0067] 3. Apply the elastic polyurethane cladding:

[0068] When impregnating the inner surface of the natural rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com