Method for eliminating leftover after chemical mechanical grinding

A chemical-mechanical, residue-based technology that is applied in the manufacture of polishing compositions containing abrasives, electrical components, and semiconductor/solid-state devices. It can solve problems such as pollutant residues, achieve high grinding rates, reduce costs, and improve reliability. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

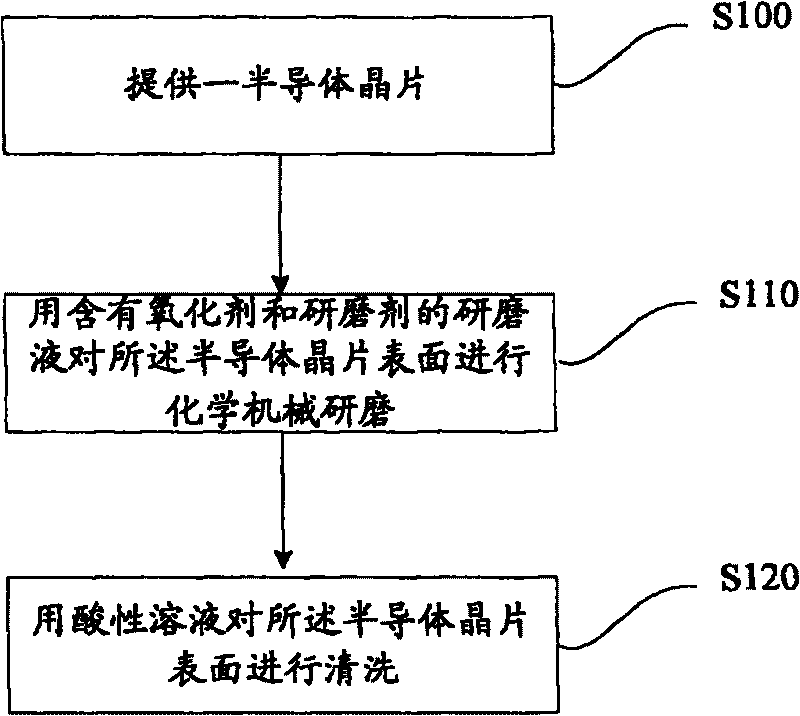

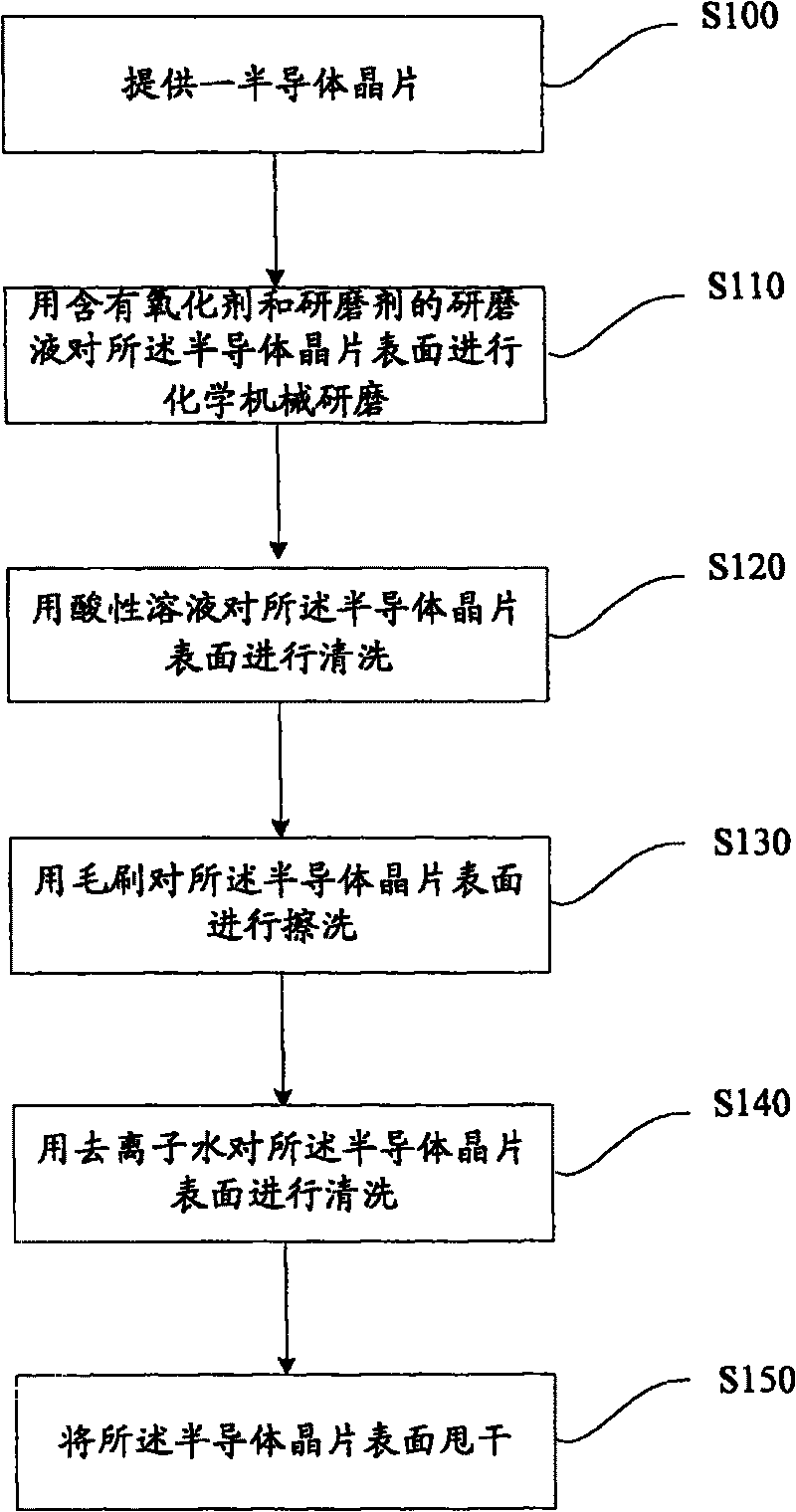

[0030] In the semiconductor manufacturing process, tungsten is often used as a connection plug to connect the semiconductor transistor device and the metal interconnection line at the back end. The process of forming the connection plug is generally a damascene process, that is, firstly, a contact hole (contact) is formed in the insulating dielectric layer through a photolithography and etching process, and then metal tungsten is deposited in the contact hole, and is planarized by chemical mechanical polishing. liquefied, followed by post-grind cleaning to remove slurry and particle contamination. The invention provides a method for removing residues after chemical mechanical grinding of tungsten, which can effectively remove residues ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com