Polyimide fibre containing benzimidazole structure and preparation method thereof

A technology of polyimide fiber and benzimidazole is applied in the field of polyimide fiber containing benzimidazole structure and its preparation field, which can solve the problem of low mechanical properties of PMDA-ODA type polyimide fiber, and achieves Improved mechanical strength, improved heat resistance, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

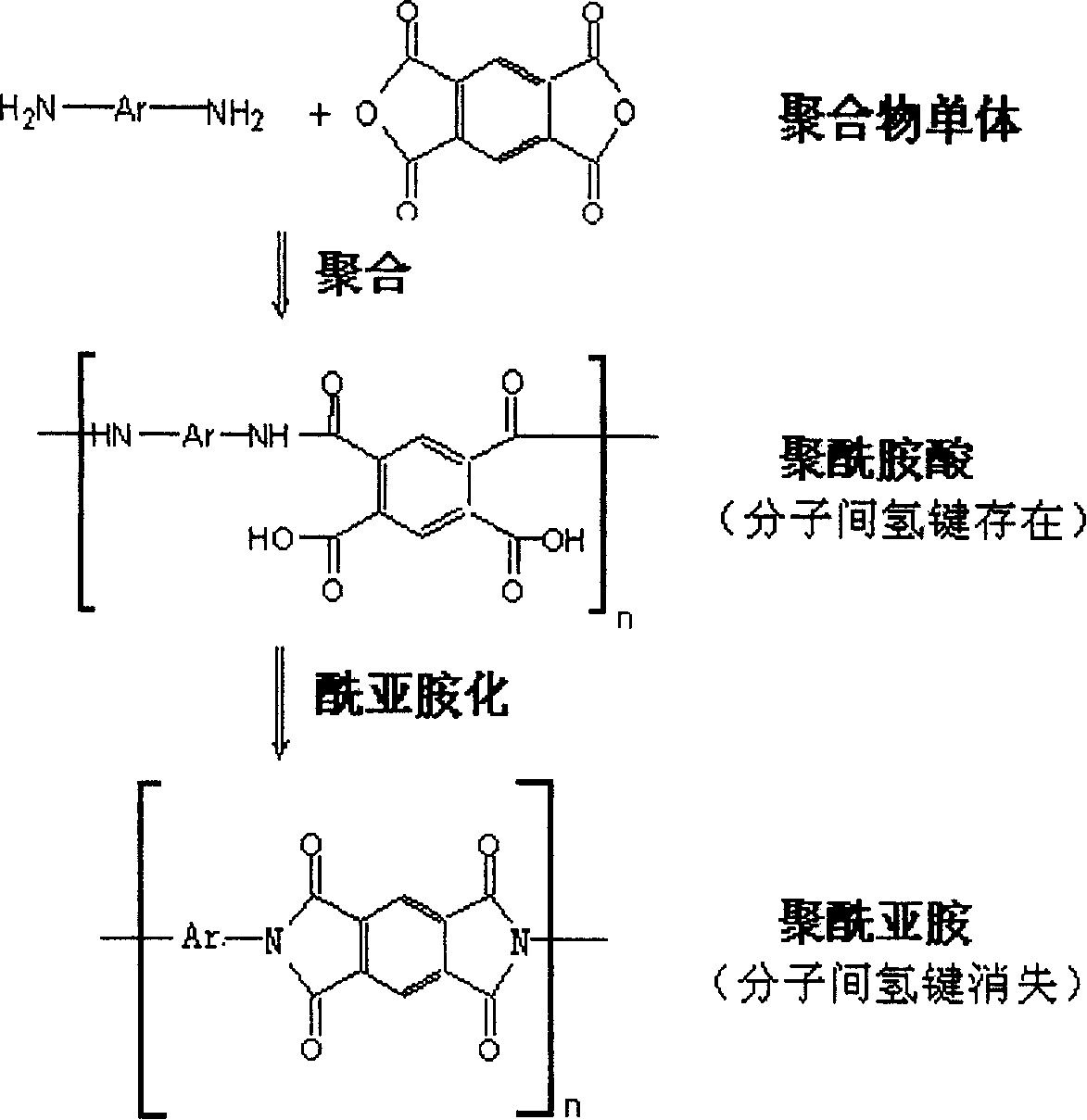

Method used

Image

Examples

Embodiment 1

[0031] The synthesis of polyamic acid solution is by PMDA: ODA: PABZ=10: 9: 1 molar ratio, first ODA and PABZ two kinds of diamine monomers are added in the solvent N-methylpyrrolidone of metering, make its total solid content be 12%, then stirred under the protection of nitrogen to dissolve all ODA and PABZ, then added PMDA and stirred, and continued to react at 15°C for 10 hours in a nitrogen atmosphere to obtain a viscous polyamic acid homogeneous solution. Its intrinsic viscosity is 3.16dL / g.

[0032] Polyamic acid fiber spinning The obtained polyamic acid solution is filtered, defoamed, and polyamic acid fiber is obtained according to the conventional dry / wet spinning process, wherein the number of spinneret holes used is 30 to 100 holes, and the hole diameter is 0.1 mm; the coagulation bath used is a mixture of ethanol and water, its weight ratio is 50:50, and the draw ratio of the fiber in the spinning stage is 1.5. In addition, the conventional wet spinning process ca...

Embodiment 2

[0037] The synthesis of polyamic acid solution is by PMDA: ODA: PABZ=10: 7: 3 molar ratio, first ODA and PABZ two kinds of diamine monomers are added in the solvent N-methylpyrrolidone of metering, make its total solid content be 12%, and then stirred under the protection of nitrogen to dissolve all ODA and PABZ, and then added PMDA and stirred to make it continue to react at 30°C for 15 hours in a nitrogen atmosphere to obtain a viscous polyamic acid homogeneous solution. Its intrinsic viscosity is 2.73dL / g.

[0038] Since the processes of polyamic acid fiber spinning and polyamic acid fiber imidization are exactly the same as those in Example 1, they are omitted here.

[0039] The structural formula of gained polyimide fiber is as shown in embodiment 1, and n in the formula: m=7: 3, and its tensile strength is 0.92GPa, and initial modulus is 56.6GPa, and elongation at break is 6.6%; The glass transition temperature is 410°C.

Embodiment 3

[0041] The synthesis of polyamic acid solution presses PMDA: ODA: PABZ=10: 5: 5 molar ratio, first adds ODA and PABZ two kinds of diamine monomers in the solvent N-methylpyrrolidone of metering, makes its solid content be 10 %, then stirred under the protection of nitrogen to completely dissolve ODA and PABZ, then added PMDA and stirred, and continued to react at 40° C. for 24 hours in a nitrogen atmosphere to obtain a viscous polyamic acid homogeneous solution. Its intrinsic viscosity is 2.35dL / g.

[0042] Since the processes of polyamic acid fiber spinning and polyamic acid fiber imidization are exactly the same as those in Example 1, they are omitted here.

[0043] The structural formula of gained polyimide fiber is as shown in embodiment 1, and n in the formula: m=5: 5, and its tensile strength is 1.26GPa, and initial modulus is 130.7GPa, and elongation at break is 5.8%; The glass transition temperature is 425°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com