Feed soybean oligosaccharide powder and manufacture method thereof

A technology of soybean oligosaccharide and a manufacturing method, which is applied in the directions of animal feed, animal feed, food preparation, etc., can solve the problems of high moisture content of soybean whey liquid, increase transportation and storage costs, and limit the scope of regional consumption, etc. Prevent and reduce morbidity, improve the effect of attracting food, and improve the effect of micro-ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

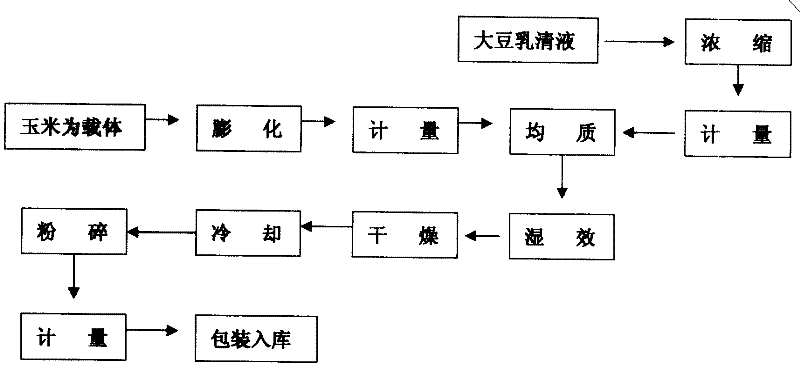

Method used

Image

Examples

Embodiment 1

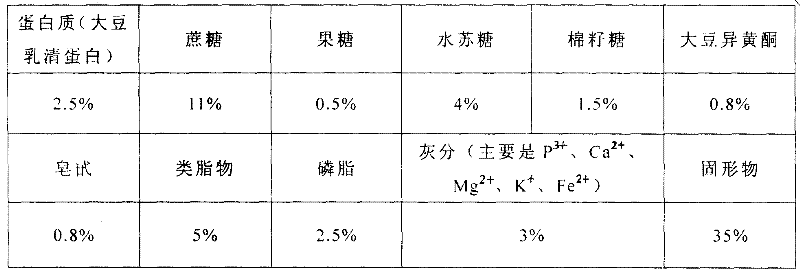

[0033] 1. Firstly, the by-product of concentrated soybean protein produced by Qinhuangdao Jinhai Food Co., Ltd.—soybean whey (soybean molasses), with a water content of 35%-70%, is concentrated through a dryer and concentrated into a large product with a water content of about 35%. Soybean whey liquid, weighing 350kg for later use;

[0034] 2. Then crush the corn (safe water), pass through a 3mm sieve, and puff the crushed corn through an extruder (dry method or wet method) at a temperature of 140°C, and weigh 150kg for use.

[0035] 3. After the above-mentioned treatment, the raw materials to be measured in proportion to be used are homogenized in batches through a twin-shaft mixer, and stirred and mixed evenly, each mixing 250kg.

[0036] 4. Place the mixed materials each time in the temporary material bin of the dryer for wet treatment, so that the mixed materials each time can be uniform as a whole.

[0037] 5. The material after homogenization and moisture treatment shou...

Embodiment 2

[0044] 1. Firstly, the by-product of concentrated soybean protein produced by Qinhuangdao Jinhai Food Co., Ltd.—soybean whey (soybean molasses), with a water content of 35%-70%, is concentrated through a dryer and concentrated into a large product with a water content of about 35%. Soybean whey liquid, weighing 250kg for later use;

[0045] 2. Then crush the corn (safe water), pass through a 3mm sieve, and puff the crushed corn through an extruder (dry method or wet method) at a temperature of 140°C, and weigh 250kg for use.

[0046] 3. After the above-mentioned treatment, the raw materials to be measured in proportion to be used are homogenized in batches by a twin-shaft mixer, stirred and mixed evenly, and mixed 500kg each time.

[0047] 4. Place the mixed materials each time in the temporary material bin of the dryer for wet treatment, so that the mixed materials each time can be uniform as a whole.

[0048] 5. The material after homogenization and moisture treatment shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com