Non-contact tonometery and device

A measurement method and non-contact technology, applied in the direction of tonometer, etc., can solve the problems of complex structure, complex corneal alignment system, complex design, etc., and achieve the effect of simple overall structure design, effective intraocular pressure measurement, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

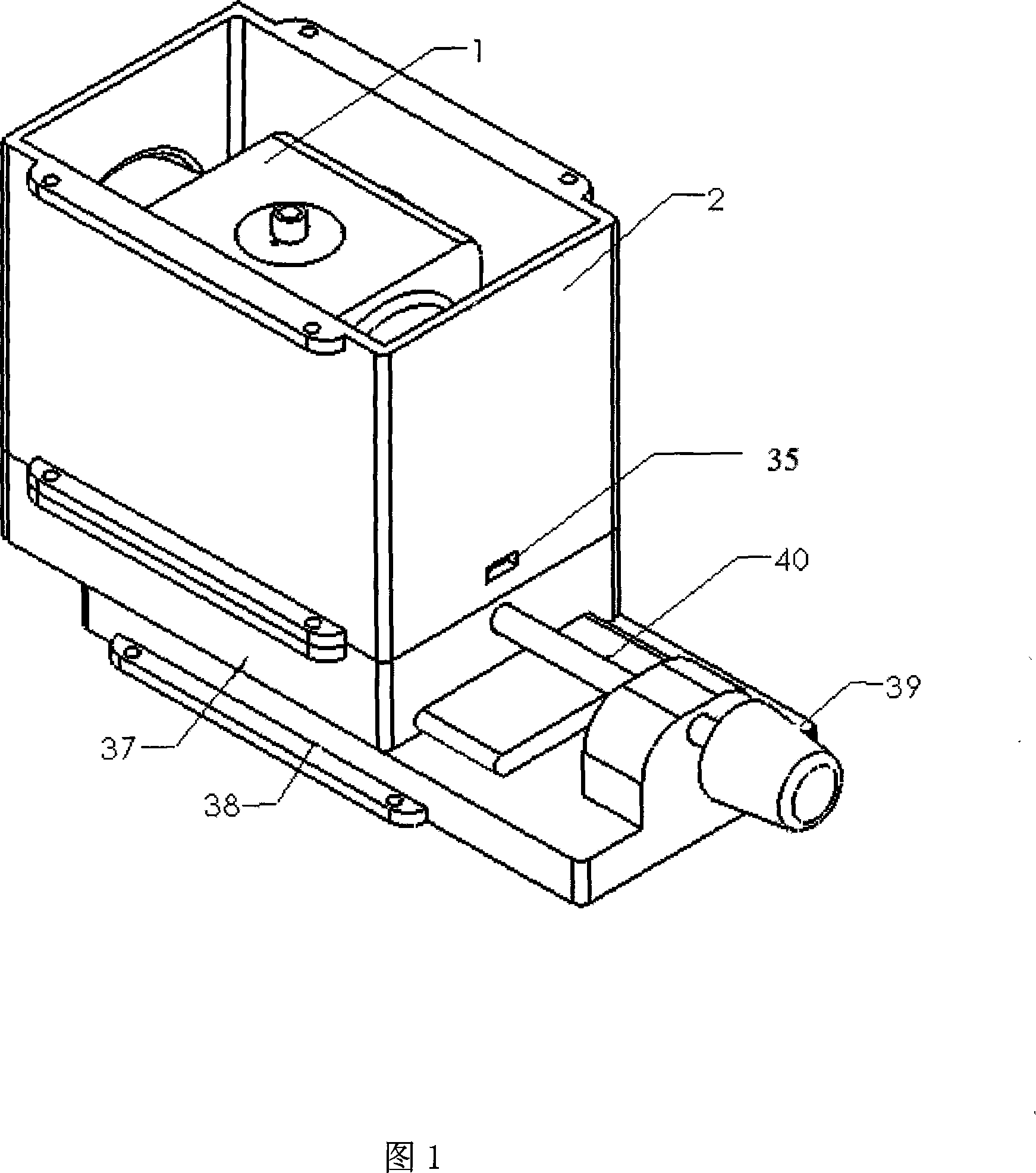

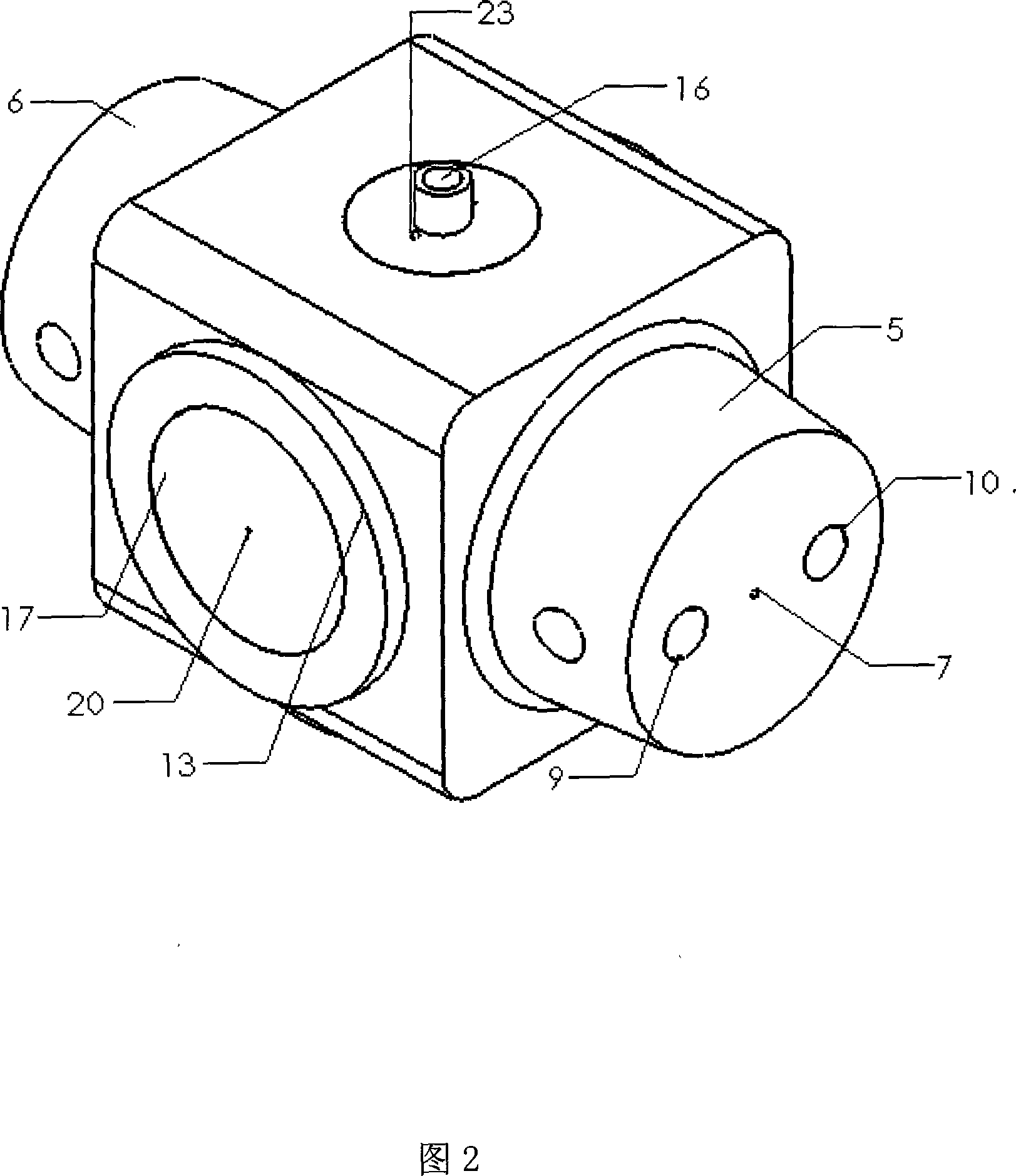

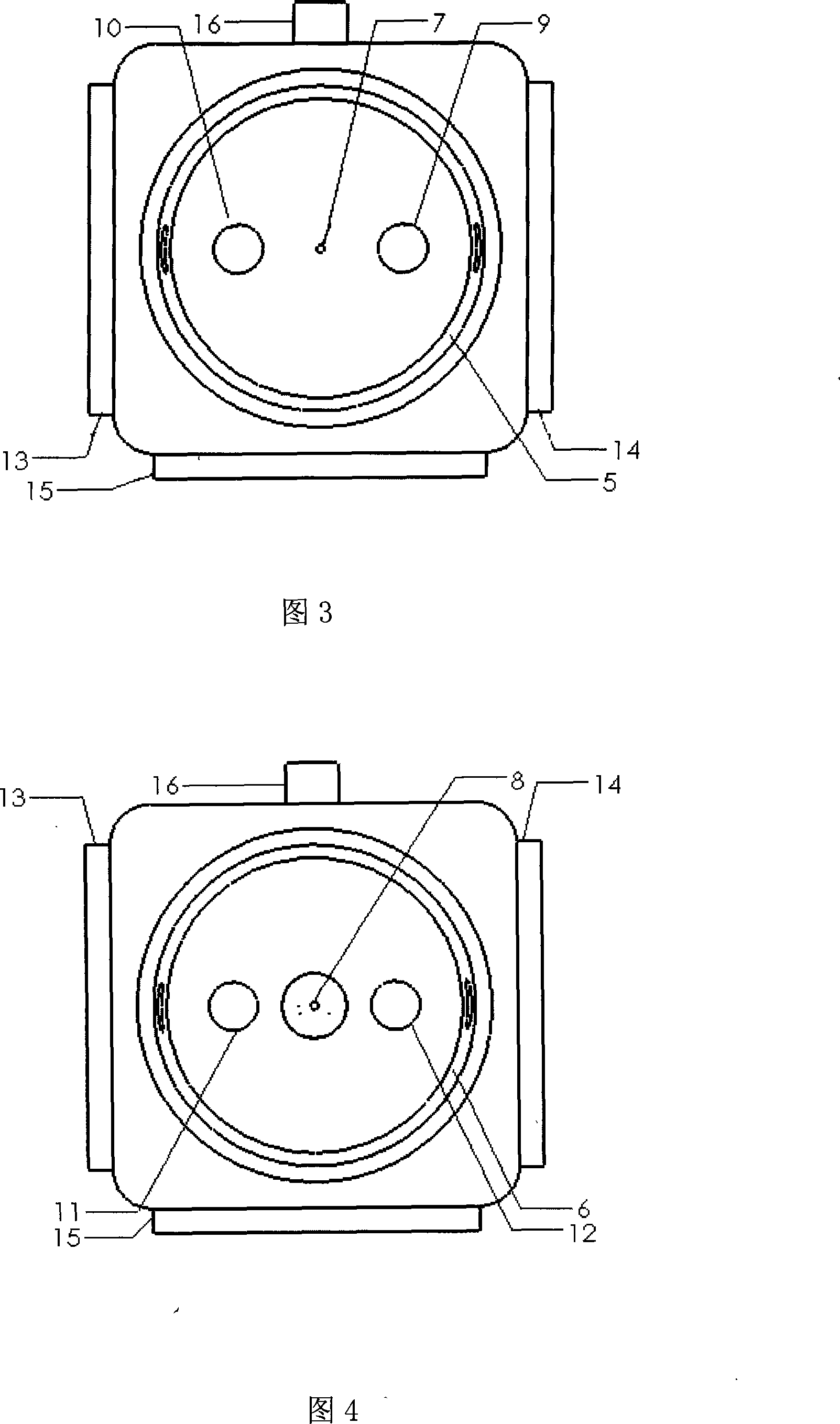

[0032] The present invention will be described in detail based on the illustrated embodiments.

[0033] Figure 2 is a perspective view of the air-floating intraocular pressure measurement module. The front and rear of the air-floating intraocular pressure measurement module are composed of two symmetrical bosses 5 and 6. As shown in Figure 3 and 4, there are nozzles 7 and 8 of the same diameter at the centers of the symmetrical bosses 5 and 6 respectively. , the diameter parameters of the nozzle are designed using the theory of hydrodynamic jet technology, and the nozzles 7 and 8 are connected to the central air cavity 26 designed by the air-floating intraocular pressure measurement module on the same horizontal line. As shown in FIG. 7 , a hole 16 is opened on the top of the air-floating tonometry module, and the hole communicates with the central air cavity 26 . As shown in Figures 5, 6, and 8, the bottom of the air-floating intraocular pressure measurement module has a bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com