Digitalis extract and preparation thereof

A technology for extracting digitalis, applied in the field of digitalis total glycosides in digitalis and its preparation, can solve the problems of extracting digitalis and not mentioning it, and achieve the effect of simple operation, high content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

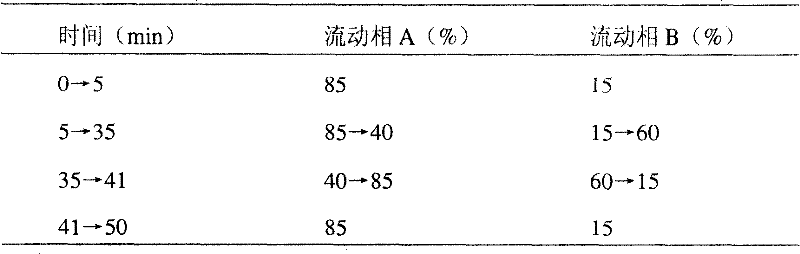

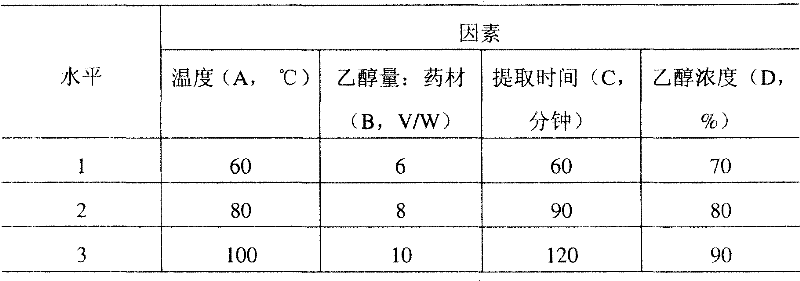

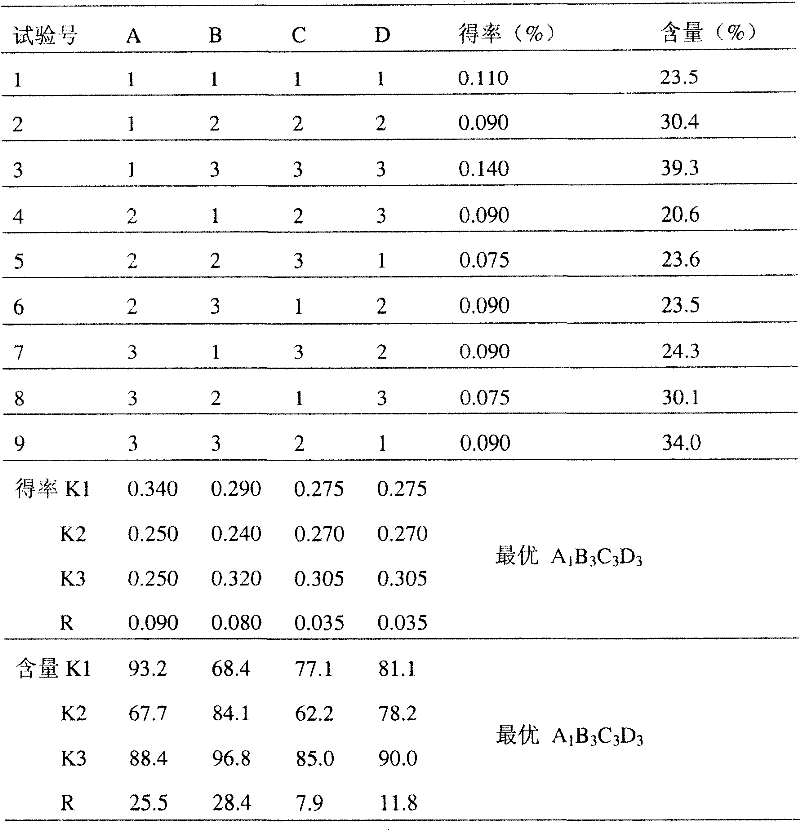

Method used

Image

Examples

Embodiment 1

[0071] Add 6 L of 70% ethanol aqueous solution to 1 kg of digitalis leaf meal, and extract under reflux at 60° C. for 60 minutes. Add 6L of 70% ethanol to the residue and extract under reflux at 60°C for 60 minutes, and combine the extracts. The resulting extract was concentrated under reduced pressure until the alcohol content was 20%, and then placed in a 4°C refrigerator overnight, filtered the next day, and after the supernatant was concentrated to remove ethanol, use one-third of the amount (based on the volume of the solution to be extracted, the next Same) petroleum ether extraction once. The water layer was recovered to dryness under reduced pressure, dissolved in 20% ethanol, extracted three times with one-third of the amount of ethyl acetate each time, and the ethyl acetate layers were combined. After the obtained ethyl acetate layer was concentrated to 800ml, the ethyl acetate layer was extracted with 80ml of 10% NaOH solution for 8 times, and then extracted once w...

Embodiment 2

[0073]Add 8 L of 80% ethanol aqueous solution to 1 kg of digitalis leaf coarse powder, and extract under reflux at 60° C. for 90 minutes. Add 8 L of 80% ethanol to the residue and extract under reflux at 60°C for 90 minutes, and combine the extracts. The resulting extract was concentrated under reduced pressure until the alcohol content was 20%, and then placed in a 4°C refrigerator overnight, filtered the next day, and after the supernatant was concentrated to remove ethanol, use one-third of the amount (based on the volume of the solution to be extracted, the next Same) petroleum ether extraction once. The water layer was recovered to dryness under reduced pressure, dissolved in 20% ethanol, extracted three times with one-third of the amount of ethyl acetate each time, and the ethyl acetate layers were combined. After the obtained ethyl acetate layer was concentrated to 800ml, the ethyl acetate layer was extracted with 80ml of 10% NaOH solution for 8 times, and then extract...

Embodiment 3

[0075] Add 10 L of 90% ethanol aqueous solution to 1 kg of digitalis leaf coarse powder, and extract under reflux at 60° C. for 120 minutes. The residue was further extracted with 10 L of 90% ethanol under reflux at 60° C. for 120 minutes, and the extracts were combined. The resulting extract was concentrated under reduced pressure until the alcohol content was 20%, and then placed in a 4°C refrigerator overnight, filtered the next day, and after the supernatant was concentrated to remove ethanol, use one-third of the amount (based on the volume of the solution to be extracted, the next Same) petroleum ether extraction once. The water layer was recovered to dryness under reduced pressure, dissolved in 20% ethanol, extracted three times with one-third of the amount of ethyl acetate each time, and the ethyl acetate layers were combined. After the obtained ethyl acetate layer was concentrated to 800ml, the ethyl acetate layer was extracted with 80ml of 10% NaOH solution for 8 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com