A kind of lactobacillus plantarum and its application in preparing boiled bamboo shoots

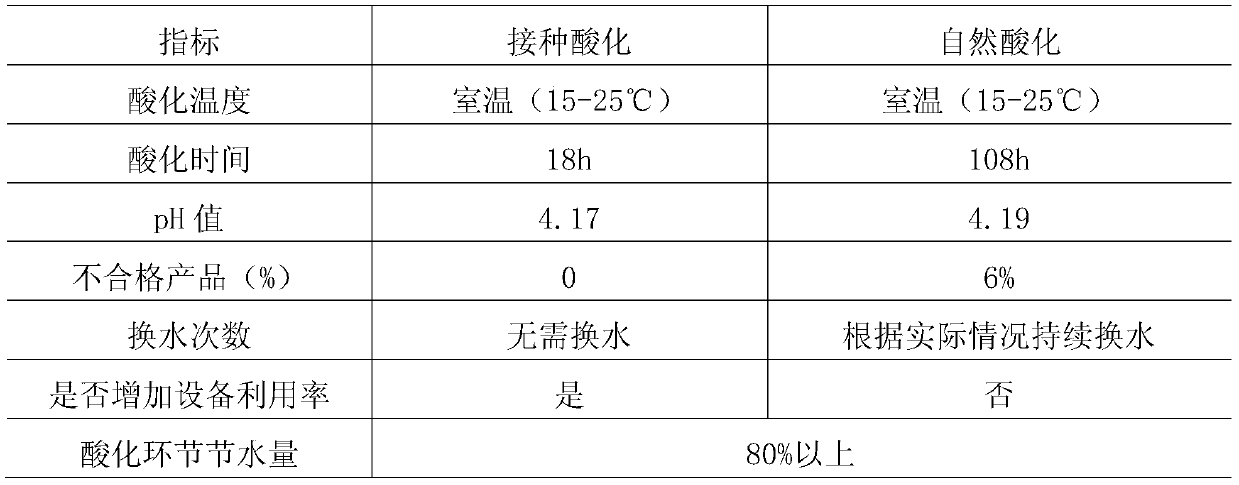

A technology of Lactobacillus plantarum and water boiling, applied in the direction of application, microbial-based methods, biochemical equipment and methods, etc., can solve the problems of long acidification process, large wastewater discharge, inconvenient quality control, etc., and achieve fine texture, Effects of reducing wastewater discharge and inhibiting bacterial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Raw material processing: remove harmful raw materials such as insect pests, overnight bamboo shoots, damaged bamboo shoots, choose fresh bamboo shoots of the day, pre-cook at 100°C (120min for large shoots, 90min for small shoots), rinse and cool in running water quickly, and remove the head and shell according to According to the corresponding standards, sorting and shaping, grading and fractal, and then weighing and filling, the bamboo shoots keep about 60% of the tank capacity;

[0047] (2) Preparation of base liquid: fresh bamboo shoots are shelled and cut into small pieces, beaten according to the ratio of bamboo shoots to water at 1:5, heated at 95°C for 35 minutes, cooled to below 45°C, filtered with a 200 mesh filter cloth to obtain the clear liquid. Bamboo shoot nutrient solution: The acidification base liquid is compounded according to the ratio of 5% bamboo shoot nutrient solution, 95% water and 0.5% sucrose;

[0048] (3) Fermentation and acidification: Inject...

Embodiment 2

[0052] In this example, the fresh bamboo shoots in step (1) are selected, pre-cooked, cooled, shaped, graded according to the corresponding standards, and finally weighed and filled; in step (2), the fresh bamboo shoots are shelled and cut into small pieces, and the water ratio is 1 : 15 beating, heating to 95°C for 15 minutes, filtering to prepare bamboo shoot nutrient solution, and preparing acidification base solution according to the ratio of nutrient solution 15%, water 85%, and sucrose 2%; step (3) activate L.Plantarum SZS001 The 5mL / L inoculum is connected to the acidification base solution, acidified for 30 hours at room temperature (15-25°C), and the pH value of the bamboo shoot meat is checked to be 3.9, and the acidification is ended; in step (4), refill the acidified boiled bamboo shoots with water , Sterilize, adjust acid, then seal, cool and store. Others are the same as in Example 1. The obtained boiled bamboo shoots have fine texture, pure aroma and no peculiar...

Embodiment 3

[0054] In this example, the fresh bamboo shoots in step (1) are selected, pre-cooked, cooled, shaped, and graded according to the corresponding standards, and finally weighed and filled; in step (2), the fresh bamboo shoots are beaten according to the shoot water ratio of 1:10, 95 Keep it at ℃ for 25 minutes to prepare bamboo shoot nutrient solution; prepare acidification base solution according to the ratio of nutrient solution 10%, water 90%, and sucrose 1%, standby, standby; in step (3), the activated L.Plantarum SZS001 is inoculated at 10mL / L Add the amount of acidification base liquid, acidify at room temperature (15-25℃) for 16 hours, check the pH of the bamboo shoots to be 4.2, and end the acidification; in step (4), refill, sterilize and adjust the acidification of the bamboo shoots in step (3). , Then seal, cool and store. Others are the same as in Example 1. The obtained boiled bamboo shoots have fine texture, pure aroma and no peculiar smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com