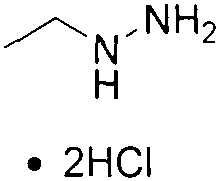

New method for synthesizing ethylhydrazine dihydrochloride

A technology of dihydrochloride and synthesis method, which is applied in the field of synthesis of ethylhydrazine dihydrochloride, can solve the problems of unavailable raw materials and low yield, and achieve the goals of easy availability of raw materials, high yield and reduction of by-products generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

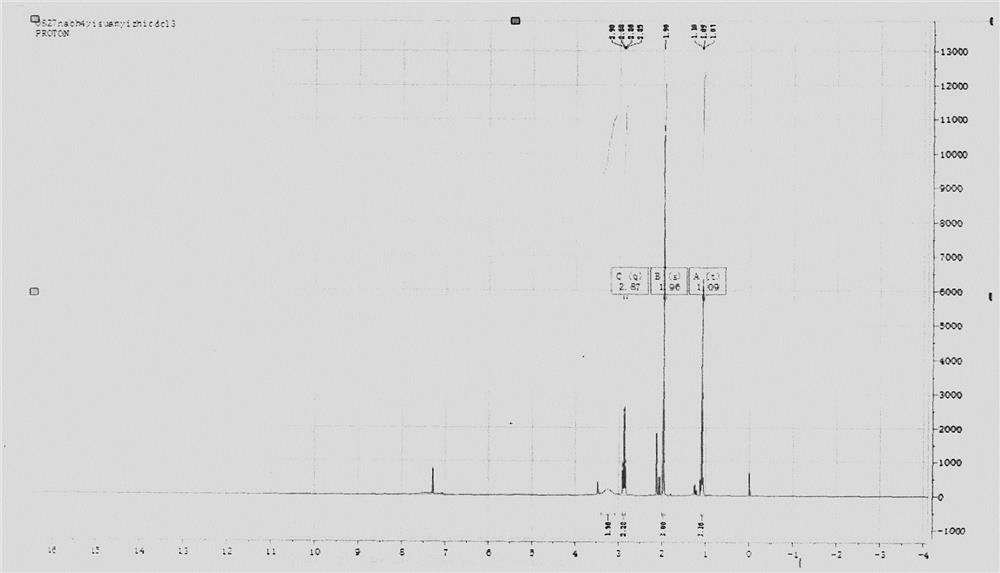

[0039] Add 100ml of acetonitrile, 20.00g of acetylhydrazide, 22.14g of anhydrous sodium acetate and 1.32g of chloro[1,3-bis(2,6-diisopropylphenyl)imidazole-2 into a 250ml four-neck round bottom flask at 0°C - Subunit] copper (I), temperature controlled dropwise addition of 58.84g of bromoethane, raised to 20°C and stirred for 12h after dropping, suction filtered and evaporated to remove the solvent to obtain 23.00g of acetyl ethylhydrazine, yield 83.42%.

Embodiment 2

[0041] Add 100ml tetrahydrofuran, 20.00g acetylhydrazide, 36.74g potassium dihydrogen phosphate and 1.32g chloro[1,3-bis(2,6-diisopropylphenyl)imidazole-2 to a 250ml four-neck round bottom flask at 0°C - Subunit] copper (I), temperature controlled dropwise addition of 58.84g bromoethane, raised to 20°C and stirred for 12h after dripping, filtered with suction, evaporated the solvent under reduced pressure to obtain 24.37g acetyl ethyl hydrazine, the yield was 88.39 %.

Embodiment 3

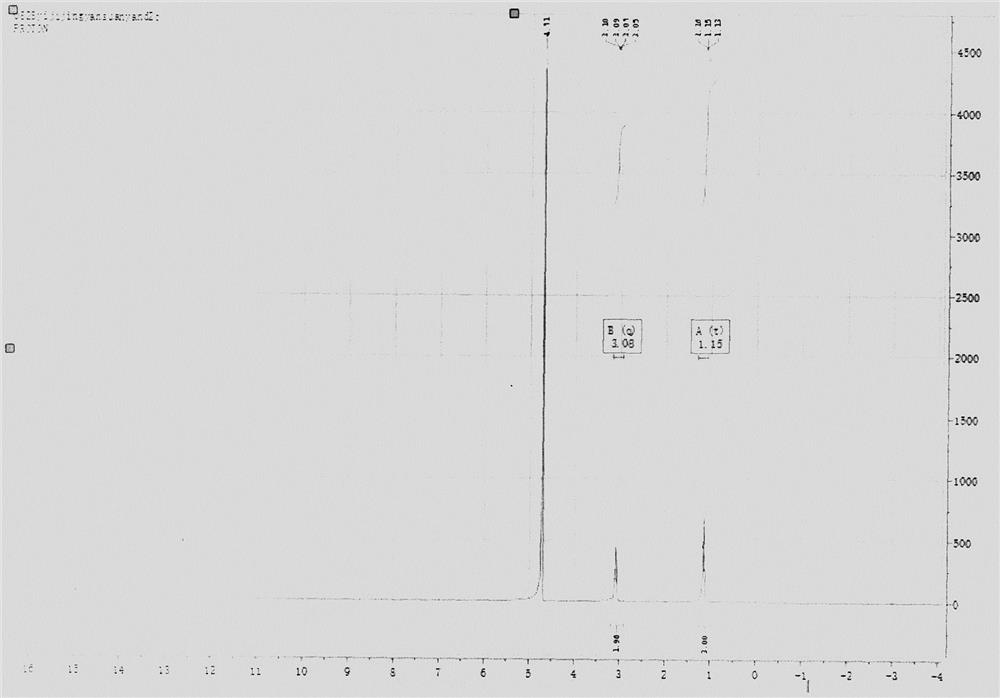

[0043] Add 100ml of methanol to a 250ml four-neck round-bottom flask, add 20g of acetylethylhydrazine at 20°C, add 49.64g of concentrated hydrochloric acid dropwise, raise the temperature to 60°C and stir for 4h after the dropwise, evaporate the solvent under reduced pressure to obtain 25.97g of ethyl hydrazine Hydrazine dihydrochloride, yield 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com