Combined stalk returning field no-tillage fertilizing and seeding machine

A seeder and straw technology, which is applied to fertilizers and sowing equipment, harvesters, planting methods, etc., can solve the problems of increased work load, heavy mechanical work load, and easy clay in the compactor, so as to reduce machine load and work load , prevent the effect of burial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

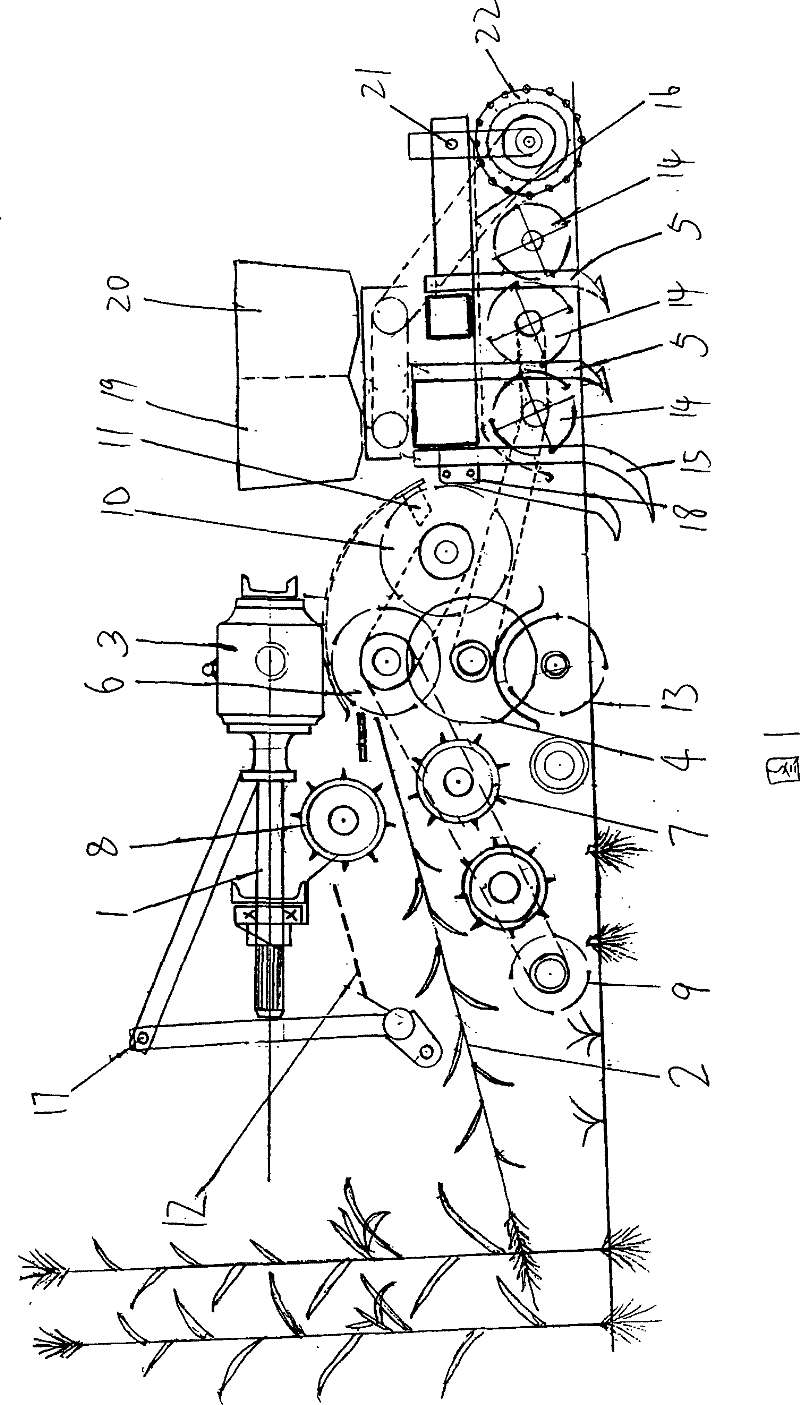

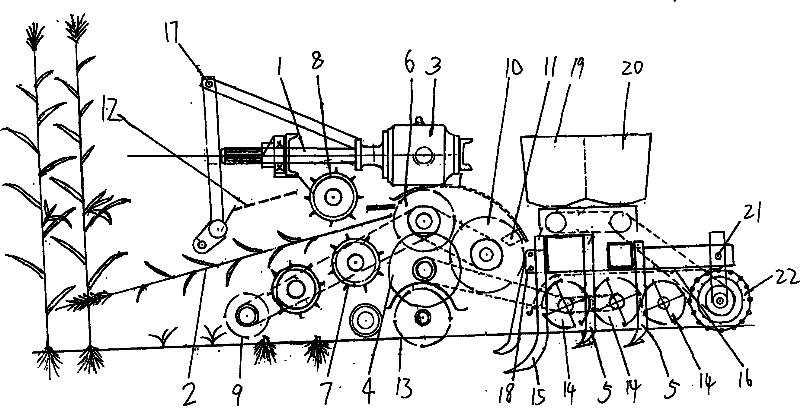

[0017] The drawings show a specific embodiment of the invention.

[0018] The combined straw-returning no-tillage fertilizer planter of the present invention includes a straw-returning device and a detachable no-tillage fertilizer seeding device connected thereafter.

[0019] In the combined straw-returning no-tillage fertilizing planter of the present invention, the straw-returning device includes a frame, a gearbox 3 that can be connected to the output shaft of the tractor's power machine, a cutting rotary knife 6, a cutting rotary knife 9, and a cutting rotary knife driven by the gearbox. Stubble cutter 13, upper feeding and squeezing wheel 8, lower feeding and squeezing wheel 7. After cutting the rotary knife, there are secondary crushing rotary knife 10 and secondary crushing fixed knife 11 at the bottom. The secondary crushing rotary knife passes through the belt pulley pair by the cutting rotary knife. Or driven by the sprocket pair. The gearbox 3 is connected to the tracto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com