Firedamp type anaerobic aerobic integrated biochemical reactor

A biochemical reactor, anaerobic and aerobic technology, used in gas production bioreactors, biochemical instruments, bioreactor/fermenter combinations, etc. It can achieve the effect of wide application, low processing cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

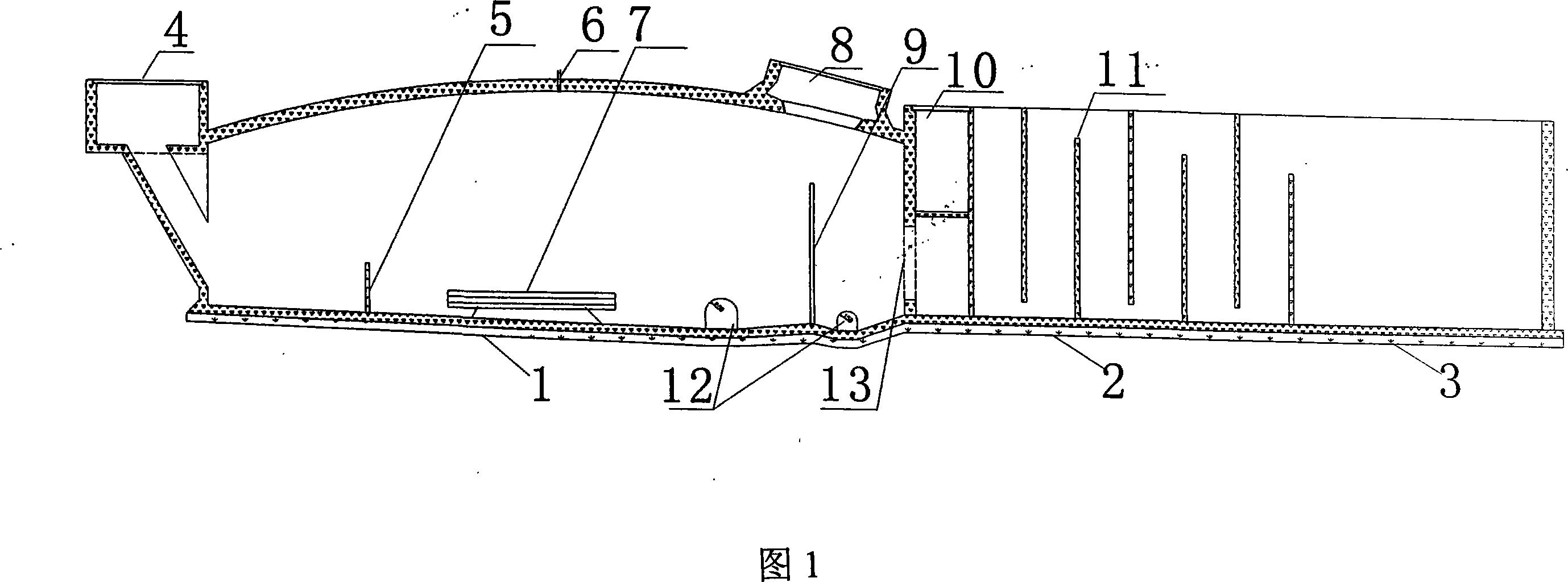

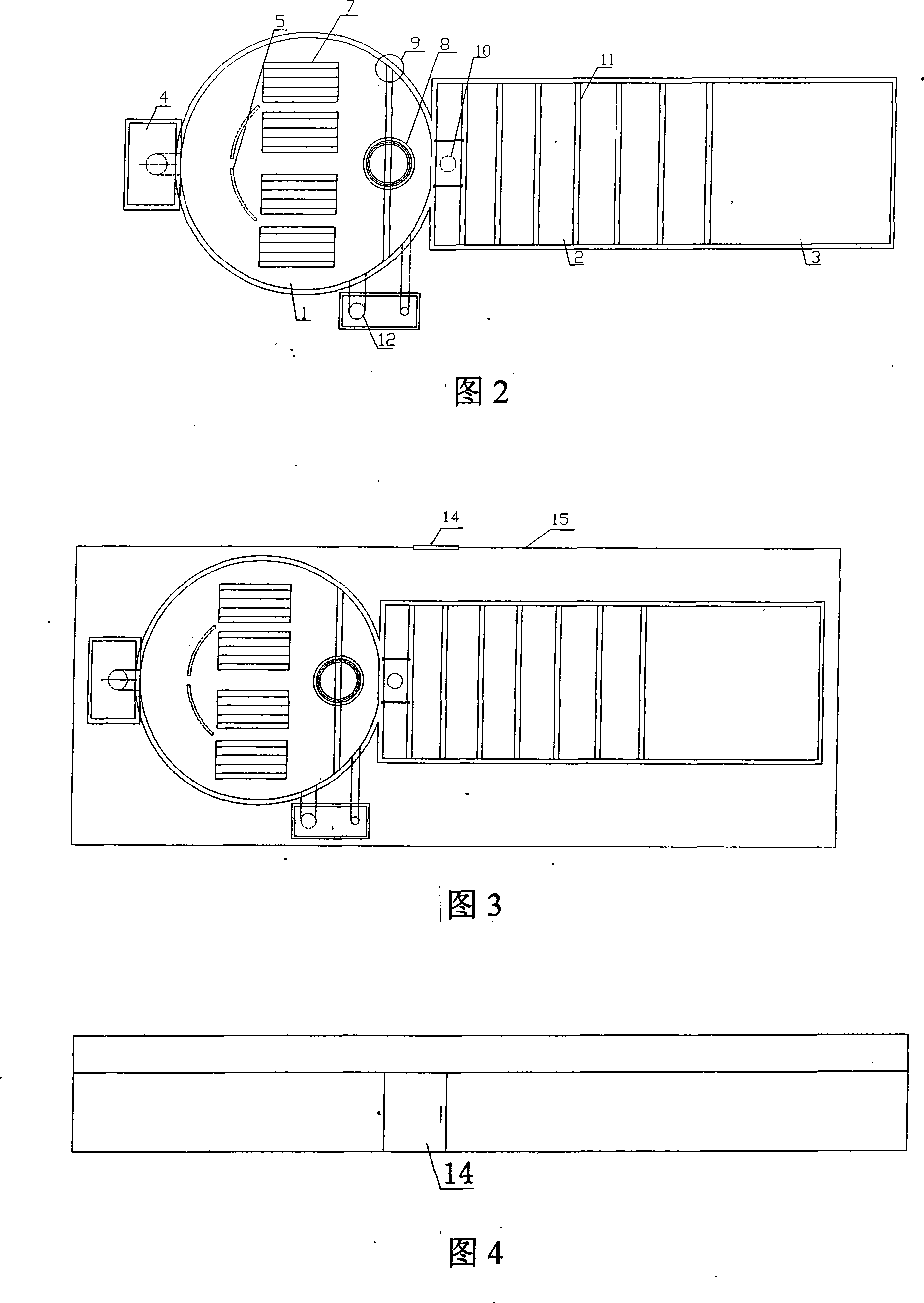

[0016] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0017] As shown in Figures 1-4, a biogas-type anaerobic-aerobic integrated biochemical reactor is characterized in that it is composed of a biogas-type anaerobic tank 1, a natural contact aerobic tank 2 and a water storage tank 3; The front end of the top of the pool 1 is provided with a feed water inlet 4, the front end of the bottom of the vertical anaerobic pool 1 is provided with a meandering flow distribution plate 5, and a heat exchanger 7 is arranged at intervals parallel to the bottom of the anaerobic pool. connection; the rear end of the vertical anaerobic pool has a baffle plate 9, and a slag outlet 12 is respectively set up on the anaerobic pool 1 wall on both sides of the baffle plate 9, and the top of the anaerobic pool 1 is provided with a biogas conduit 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com